Textile cutting device

A cutting device and textile technology, applied in the field of textiles, can solve problems such as difficult tool replacement, inability to remove wrinkles, and inability to change cutting shapes, etc., to achieve the effects of improving efficiency, not being prone to cracks, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

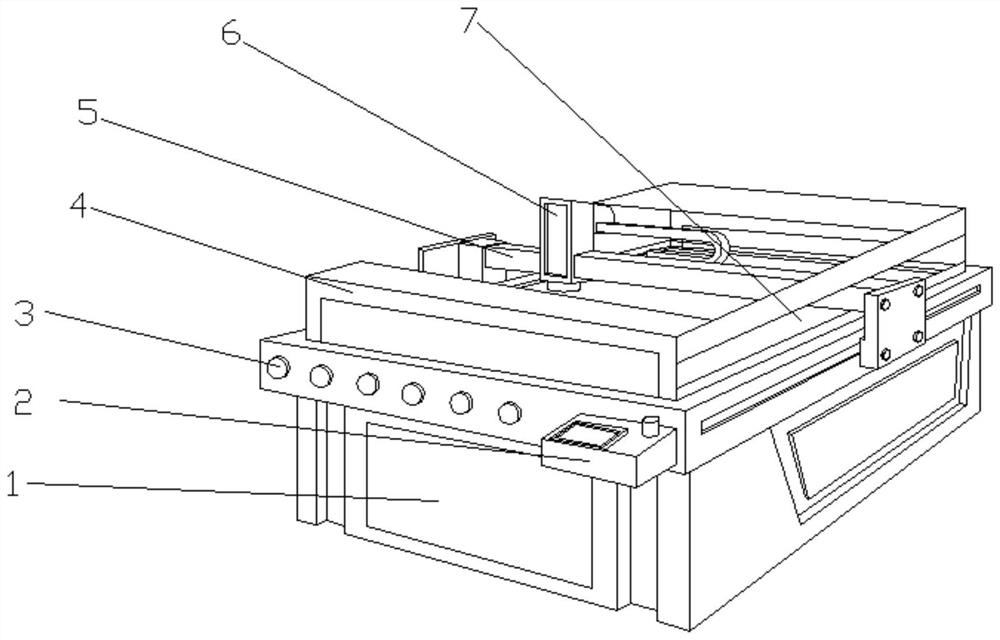

[0035]Such asFigure 1-3 One technical solution proposed in the present invention: a textile cutting device, including a base 1, a bottom fixed connection between the base 1, and the front side of the operating table 3 fixedly connected to the controller 2, the operation stage 3 The side is provided with a motor 5, and a cutting device 6 is provided on the top left side of the top portion of the mount 5, and the top portion of the operating table 3 is fixedly connected to the protective device 4, and the sidewall 7 is provided on both sides of the guard 4, and the middle of the mount 5 is run through. Slide 7.

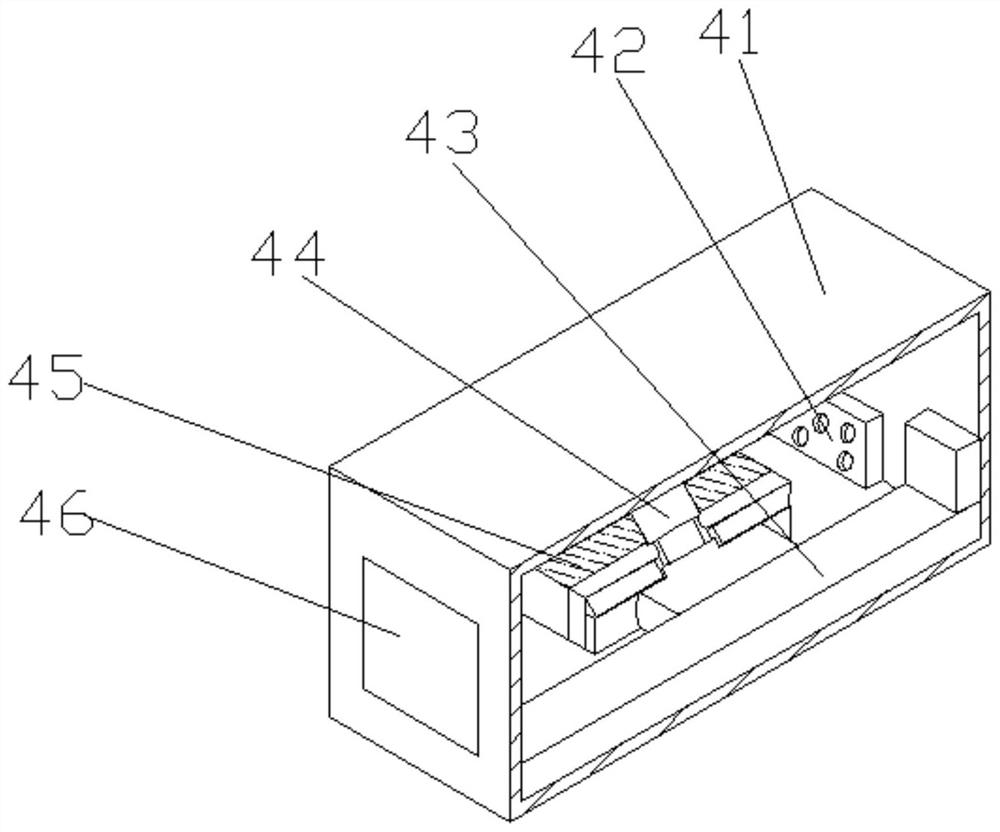

[0036]Wherein, the protective device 4 includes a frame 41, and a clamping mechanism 43 is provided with a clamping mechanism 43 in the front side of the outer casing 41, and the intermediate position of the outer casing 41 is fixed to the intermediate position of the separator 45, and the middle cavity of the separator 45 is provided. The support shaft 44, the intermediate posi...

Embodiment 2

[0040]Such asFigure 1-4 As shown, in the basis of the first example, the present invention provides a technical solution: the clamping mechanism 43 includes a bracket 434, and the middle portion of the front portion of the bracket 434 is opened, and the inner wall of the grip groove 435 is fixedly connected. There is a fixed teeth 436, and the top two sides of the bracket 434 are fixedly connected to the fixed block 431, and the lumen bottom of the fixing block 431 is fixedly coupled to the side slide 433, and the top portion of the side slide 433 is provided with a hosted frame 432.

[0041]When used, from the box door 46 is placed in the material, press the start button on the controller 2, the mount 5 drives the cutting device 6 on the operating table 3 by the chute 7, and the material is more vivid to the inside of the device. The case where the material cutting will be clamped, the box door 46 can perform the internal cleaning, the through hole 42 performs internal ventilation, ma...

Embodiment 3

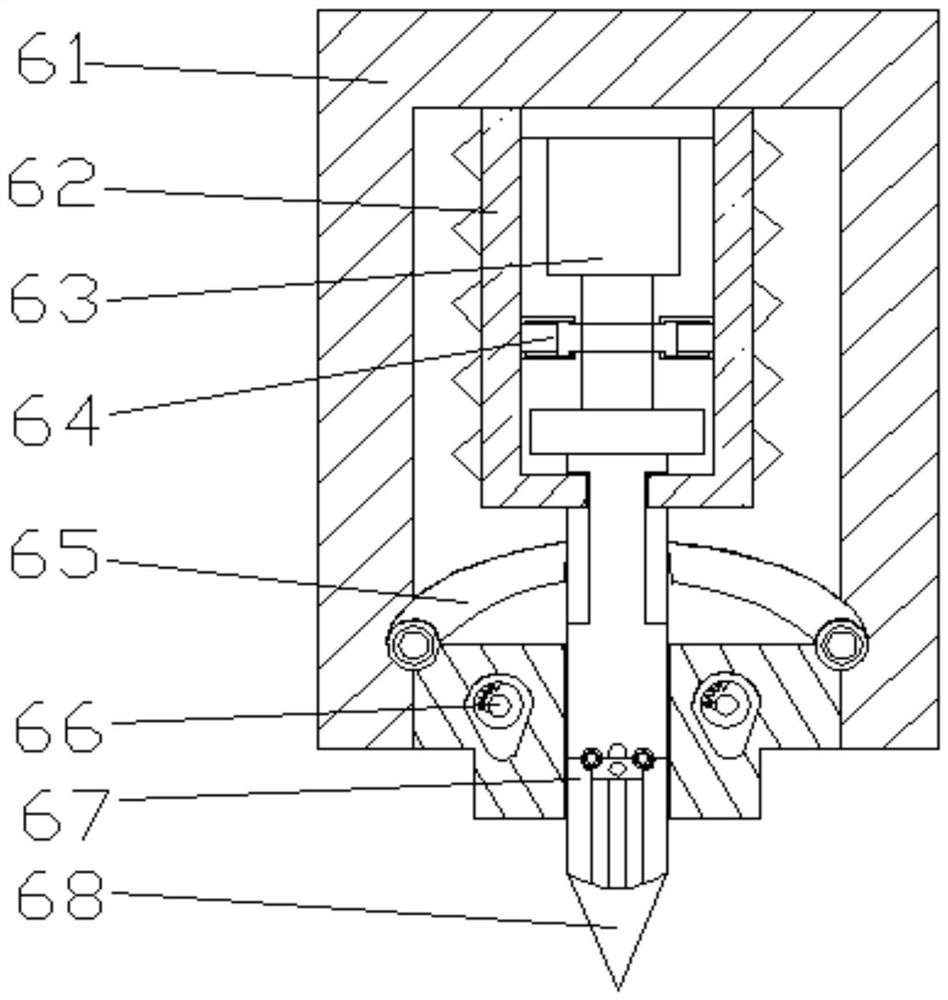

[0043]Such asFigure 1-6As shown, in the basis of the first embodiment, the present invention provides a technical solution: the drive mechanism 65 includes a bottom plate 652, and the top portion of the bottom plate 652 is fixedly connected to the upper plate 651, the bottom plate 652 is fixedly connected. There is a regulating mechanism 653, and the intermediate position of the bottom plate 652 is fixed to the outer extension rod 654, and the intermediate position of the outer extension rod 654 is fixedly connected to the pull block 655.

[0044]Wherein, the regulating mechanism 653 includes a carrier plate 6533, and the top portion of the carrier plate 6533 is provided with a swing block 6532, and the internal shrinkage block 6532 is provided. The upper left side of the swift block 6531 is provided with a front plate 6534, a swift block 6531 The contact ball 6535 is fixed to the position close to the front plate 6534.

[0045]When used, from the box door 46 is placed in the material, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com