Efficient injection-suction type hydraulic impactor

A hydraulic impactor and ejector-suction technology, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and production, etc., can solve the problems of high start-up and working pressure, unstable performance, and low energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

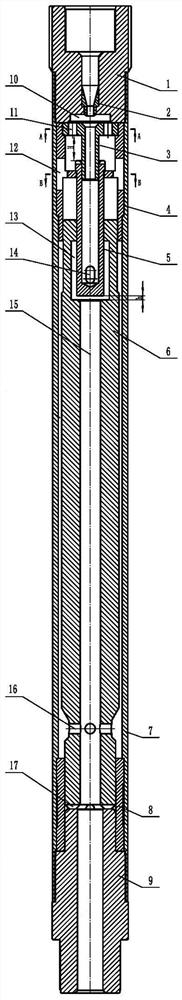

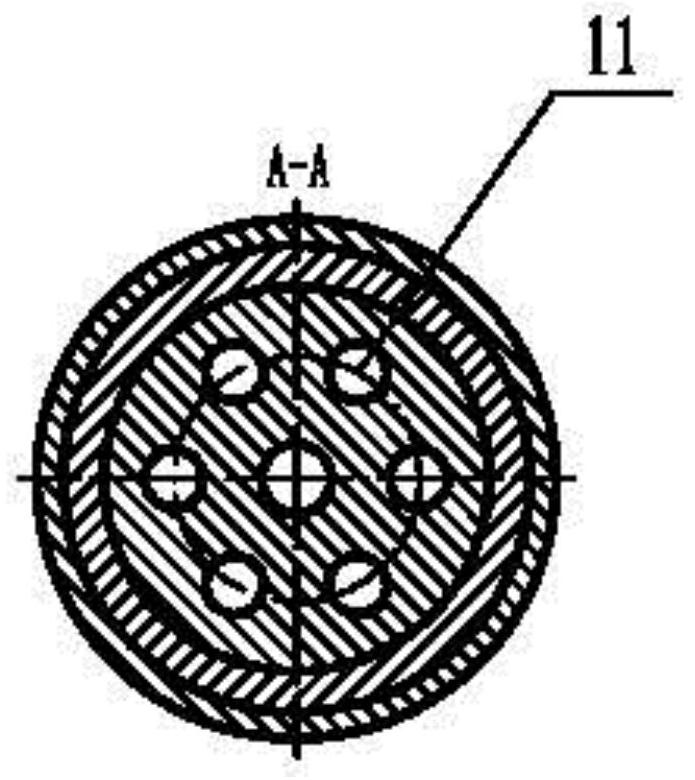

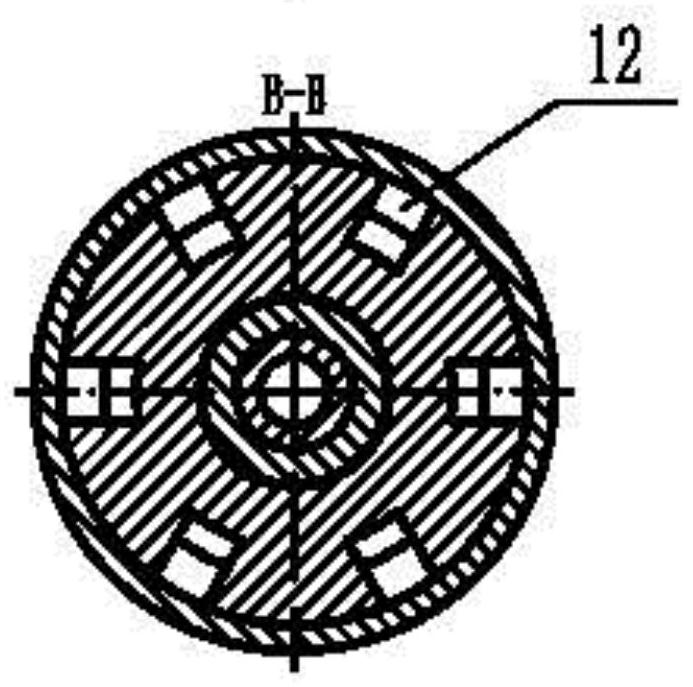

[0034] As shown in Figure 1, a high-efficiency jet-suction hydraulic impactor provided by the present invention includes an upper joint 1, a nozzle 2, a nozzle holder 3, a limit guide sleeve 4, a live valve 5, and an impact hammer rod 6. Outer pipe 7, lower cylinder liner 8, impact anvil joint 9. The lower end surface of the upper joint 1 is provided with an inner counterbore 10 with a depth of 1 mm to 20 mm, and a cavity space is formed between the inner counterbore 10 and the injector 3 . The upper part of the upper joint 1 is threadedly connected with the drill pipe, and the nozzle 2 is pressed into the center hole of the upper joint 1 through interference fit. The position is fixed, the taper of the inner taper hole at the upper part of the nozzle 2 is 0°~150°, and the diameter of the inner hole at the lower end is 1.5mm~50mm.

[0035] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com