Continuous axial impact rock breaking hammer

An axial impact and rock-breaking technology, which is applied in the direction of drilling equipment, earthwork drilling, and rotary combined drilling drive devices, can solve the problems of short service life, long structure, small impact force, etc., and achieve short overall length, The effect of high life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

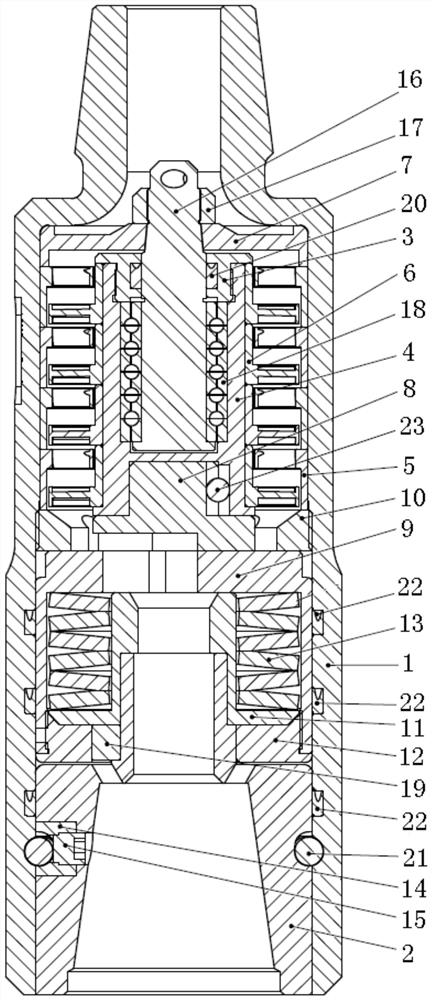

[0044] Such as figure 1 , figure 2As shown, a continuous axial impact rock breaking hammer includes a casing 1, the upper end of the casing 1 is designed with a male joint; the upper end of the casing 1 is provided with a bearing shaft 16, and the upper end of the bearing shaft 16 is fitted with a stator top ring 7, and the stator top top The ring 7 is fixed on the inner wall of the housing 1, the rotor lock nut 3 is set in the middle of the bearing shaft 16 and is sealed with the bearing shaft 16, the bearing string 18 is placed at the lower end of the rotor lock nut 3 and is set on the bearing shaft 16, and the inside of the rotor The sleeve 4 is set on the outer side of the bearing string 18, and the outer wall of the rotor inner sleeve 4 is axially and sequentially equipped with a plurality of turbine rotors 6, and the rotor lock nut 3 is threaded on the upper end of the rotor inner sleeve 4 and compresses the turbine rotor 6. The turbine stator 5 is installed on the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com