Hydraulic holding hook short-connection assembly for engineering drilling machine

An engineering drilling rig and hydraulic technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of high time consumption and difficulty in getting started, and achieve the effect of saving time and cost, improving work efficiency and facilitating splicing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the invention is not limited to these embodiments.

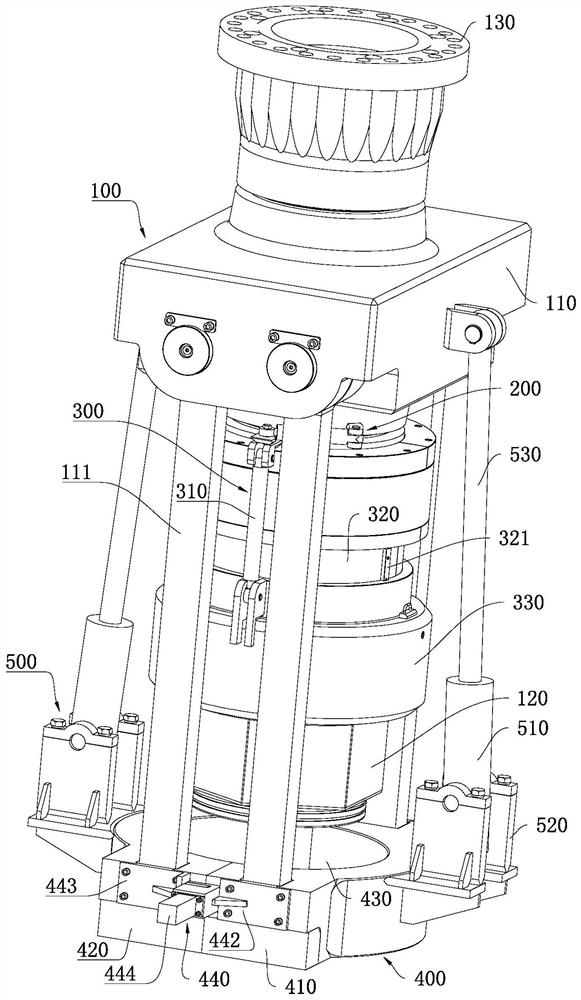

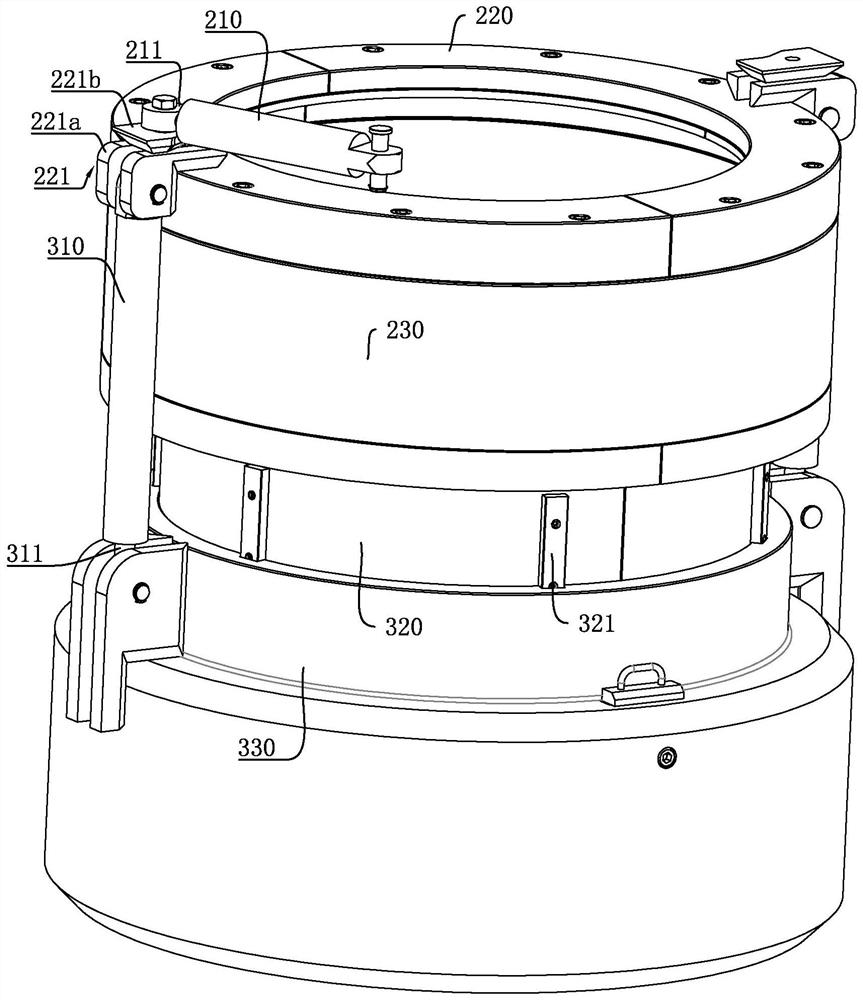

[0028] like Figure 1-3 As shown, a hydraulic hook shorting assembly for engineering drilling rigs, including:

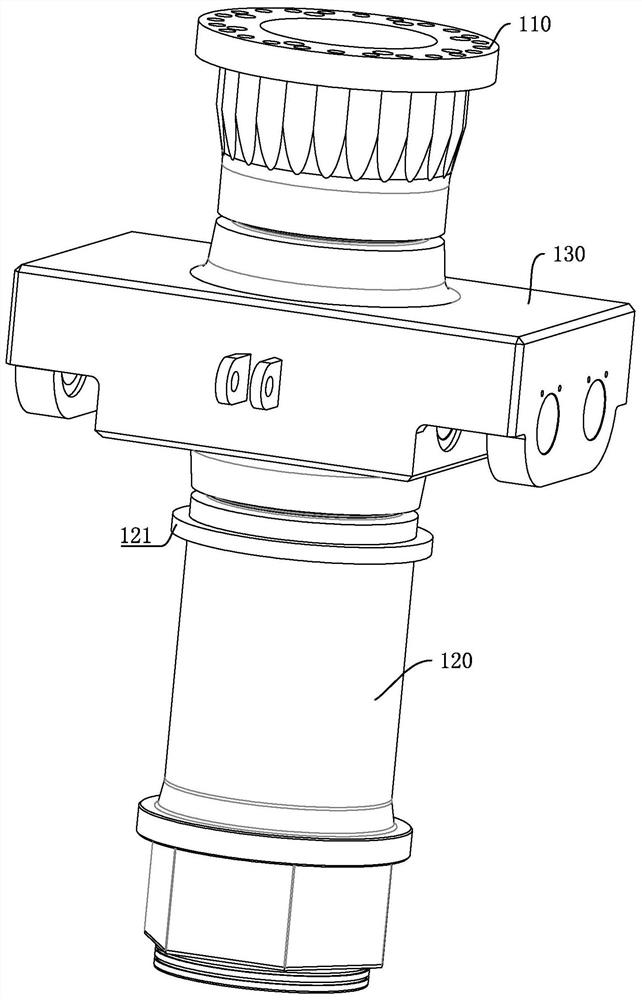

[0029] Hydraulic hook socket 100, hydraulic hook socket 100 includes a square seat 110, a joint 120 and an upper flange 130, the upper flange 130 is fixed above the square seat 110, and the joint 120 is movably arranged below the square seat 110. The flange 130 is used to fix the overall device on the engineering drilling rig, and the center position of the lower parts can be adjusted through the upper flange 130 to ensure that the center position of the joint 120 is on the same vertical line as the center position of the drilling tool. The seat 110 is used to connect the joint and the upper flange 130. The joint 120 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com