Safe inflation device

An inflatable device, a safe technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems of high opening pressure, limited exhaust speed, and inability to reduce, and achieve rapid exhaust pressure relief, The effect of ensuring safety and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

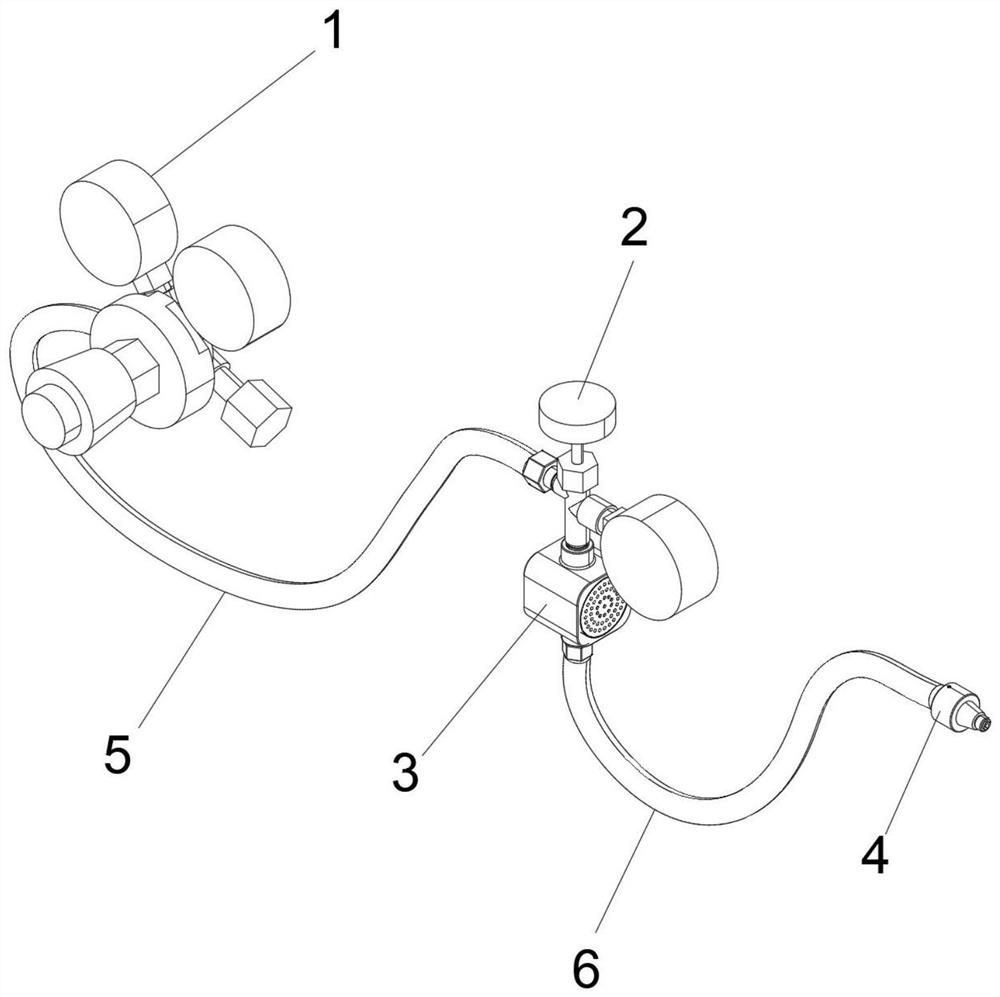

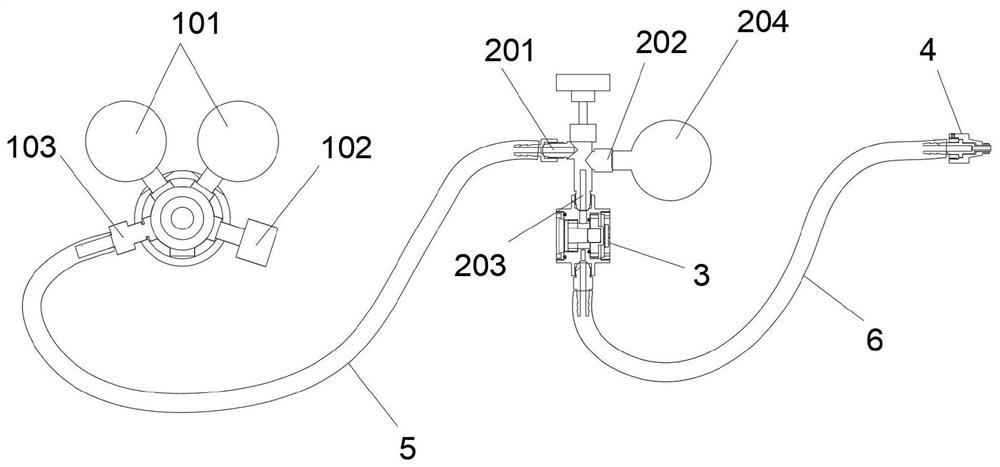

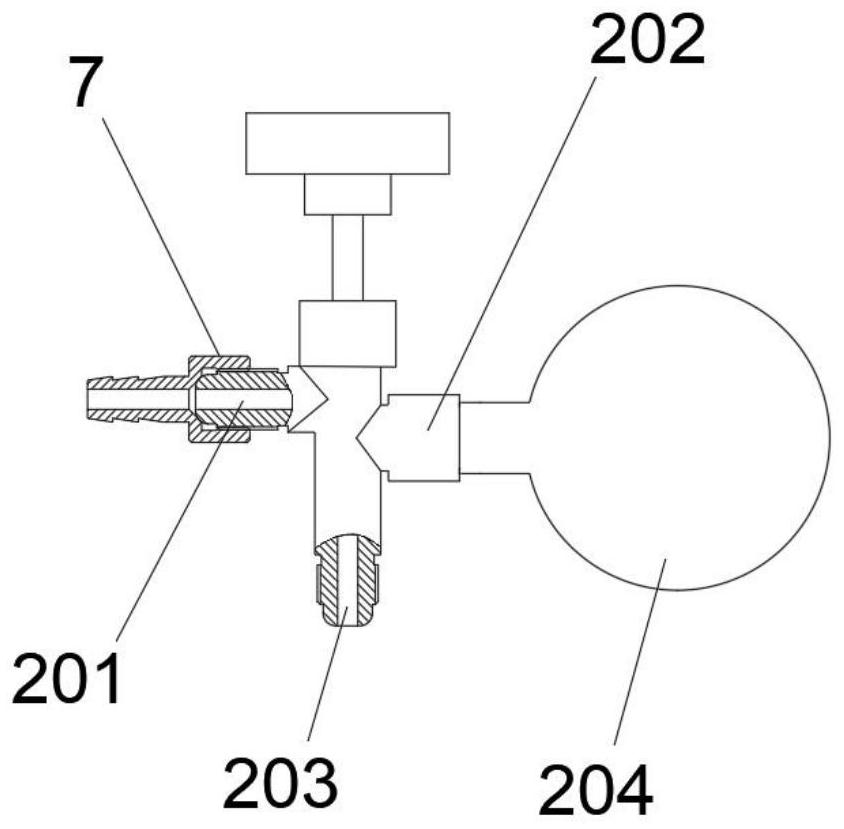

[0022] like figure 1 As shown, the technical solution of this embodiment includes a pressure reducer 1, a three-way valve 2, a safety valve 3 and an anti-twisting air nozzle 4. 5 is connected to the air inlet 201 of the three-way valve 2. There are two air outlets on the three-way valve 2, one of which is equipped with a small-range pressure gauge 204 on the air outlet 202, and the other air outlet 203 is connected to the air inlet of the safety valve 3. The air outlet 307 of the safety valve 3 is connected to the anti-twisting air nozzle 4 through the low-pressure pipe 6, and the anti-twisting air nozzle 4 is used to connect the air filling port of the optical cavity; the safety valve 3 is provided with an air pressure adjustment device , which can release the pressure of the high-pressure gas passing through the safety valve 3 .

[0023] In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com