Automatic Tube Brush Online Cleaning System

A cleaning system and fully automatic technology, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, etc., can solve the problems of many types and quantities of parts, high manufacturing and maintenance costs, and complicated manufacturing processes, so as to achieve convenient operation and low manufacturing cost. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

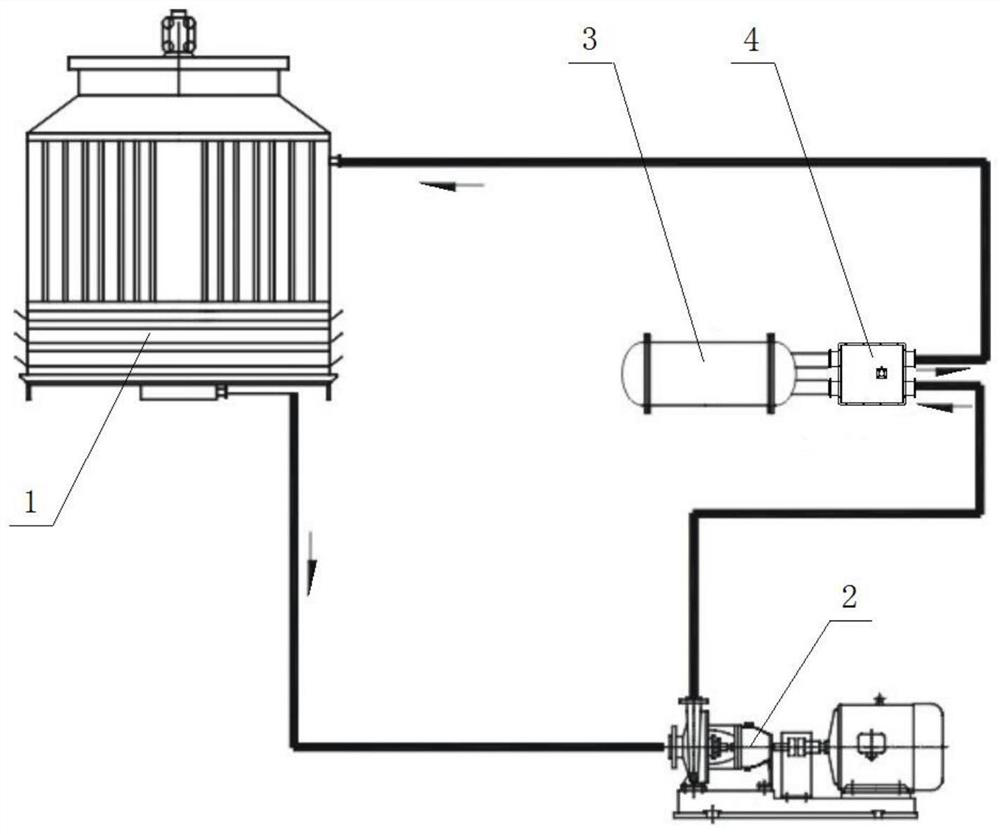

[0045] Such as figure 1 As shown, a fully automatic tube brush online cleaning system is placed in a water circulation loop composed of a cooling tower 1, a cooling water pump 2 and a heat exchanger 3. It specifically includes a sliding brush assembly (the sliding brush assembly is composed of a nylon brush and a brush basket), a four-way reversing valve 4 and a control system, wherein the four-way reversing valve 4 is used to control the reversing of the water flow of the heat exchange tube in the heat exchanger flow.

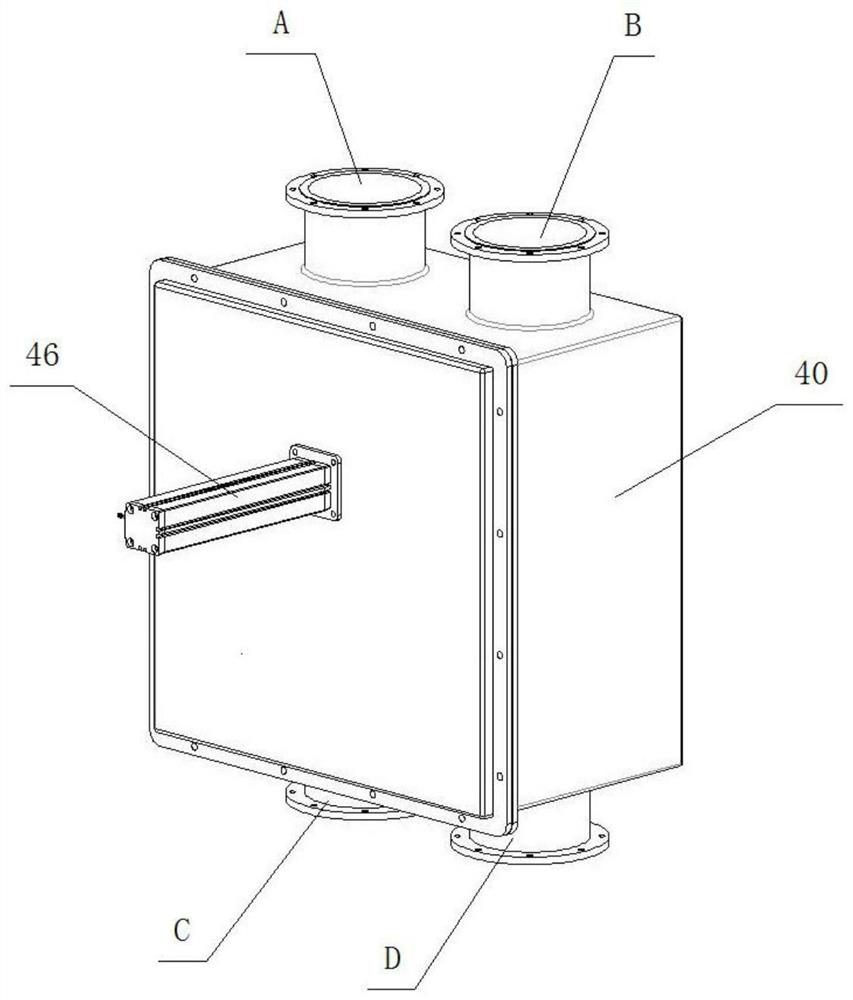

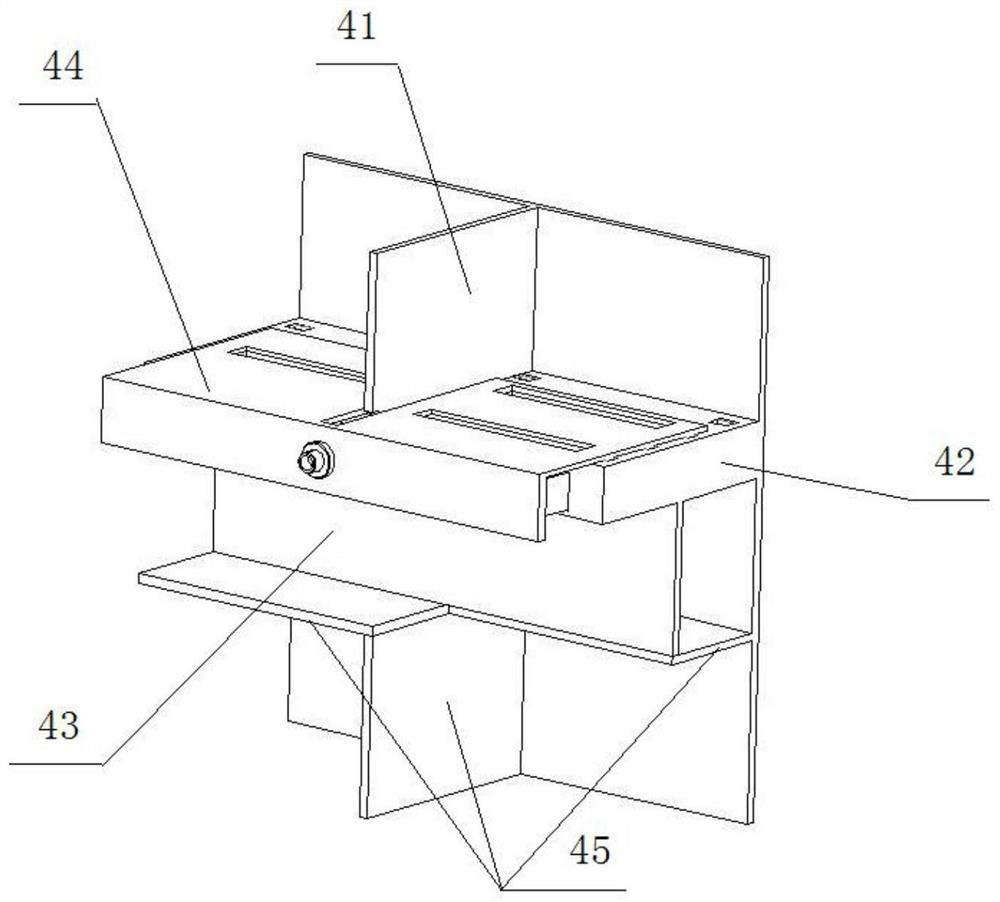

[0046] Such as Figure 2 to Figure 8 As shown, the shell 40 of the four-way reversing valve 4 is provided with four interfaces ABCD, wherein the A, B interfaces are respectively connected to the water inlet and the water outlet of the waterway, and the C, D interfaces are respectively connected to the water inlet and the water outlet of the heat exchange tube. The water outlet is connected.

[0047] The casing 40 is a rectangular box, and in the rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com