Sorting machine for processing electronic components

A technology for electronic components and sorting machines, applied in sorting and other directions, can solve problems such as inspection accuracy errors, photographing area restrictions, and different lighting environments, and achieve the effects of reducing production costs, improving processing speed, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Referring to the accompanying drawings, preferred embodiments according to the present invention will be described, and for the sake of conciseness of description, descriptions on repeated or substantially identical configurations will be omitted or compressed as much as possible.

[0059]

[0060] For the tray T, for example, the technology of Korean Laid-Open Patent No. 10-2008-00406541 can be referred to.

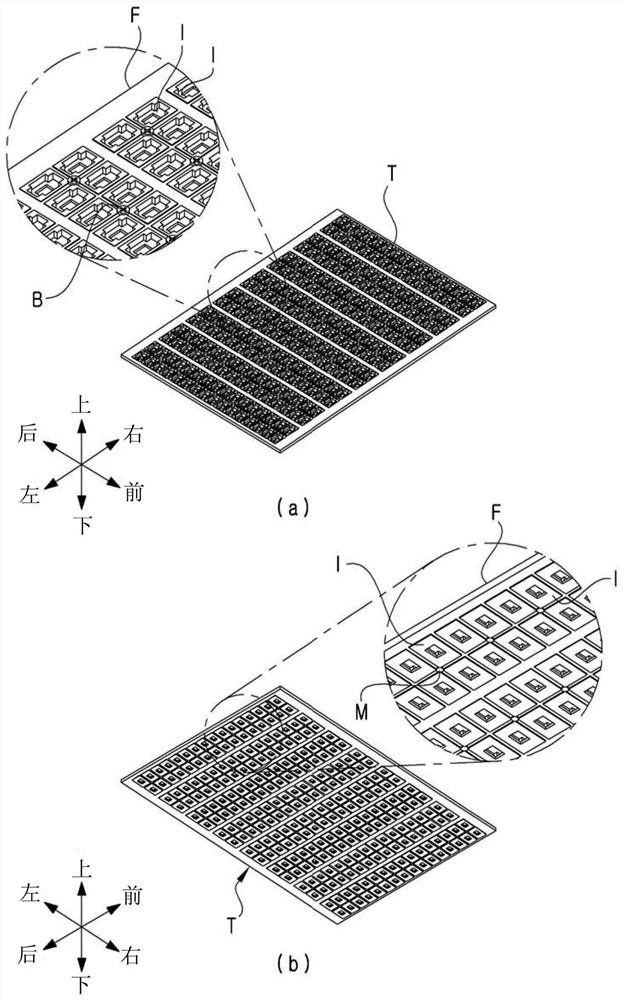

[0061] figure 1 (a) and (b) are a schematic plan perspective view and bottom perspective view about the tray T.

[0062] Tray T is equipped with frame F and insert I.

[0063] The frame F constitutes the skeleton of the tray T, and the inserts I are arranged on the frame F in a row of 16×16.

[0064] As is well known, the interposer 1 has a housing space for housing electronic components, and has a latch for securing the electronic components housed in the housing space.

[0065] and, figure 1 The tray T has the following structure: four inserts I in a 2×2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com