Circuit board transferring apparatus and method and solder ball mounting method

一种电路基板、搬运装置的技术,应用在电路、送锡装置、辅助装置等方向,能够解决焊球吸附管嘴排列不一致、焊盘精度差、无法焊球准确地搭载搭载等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

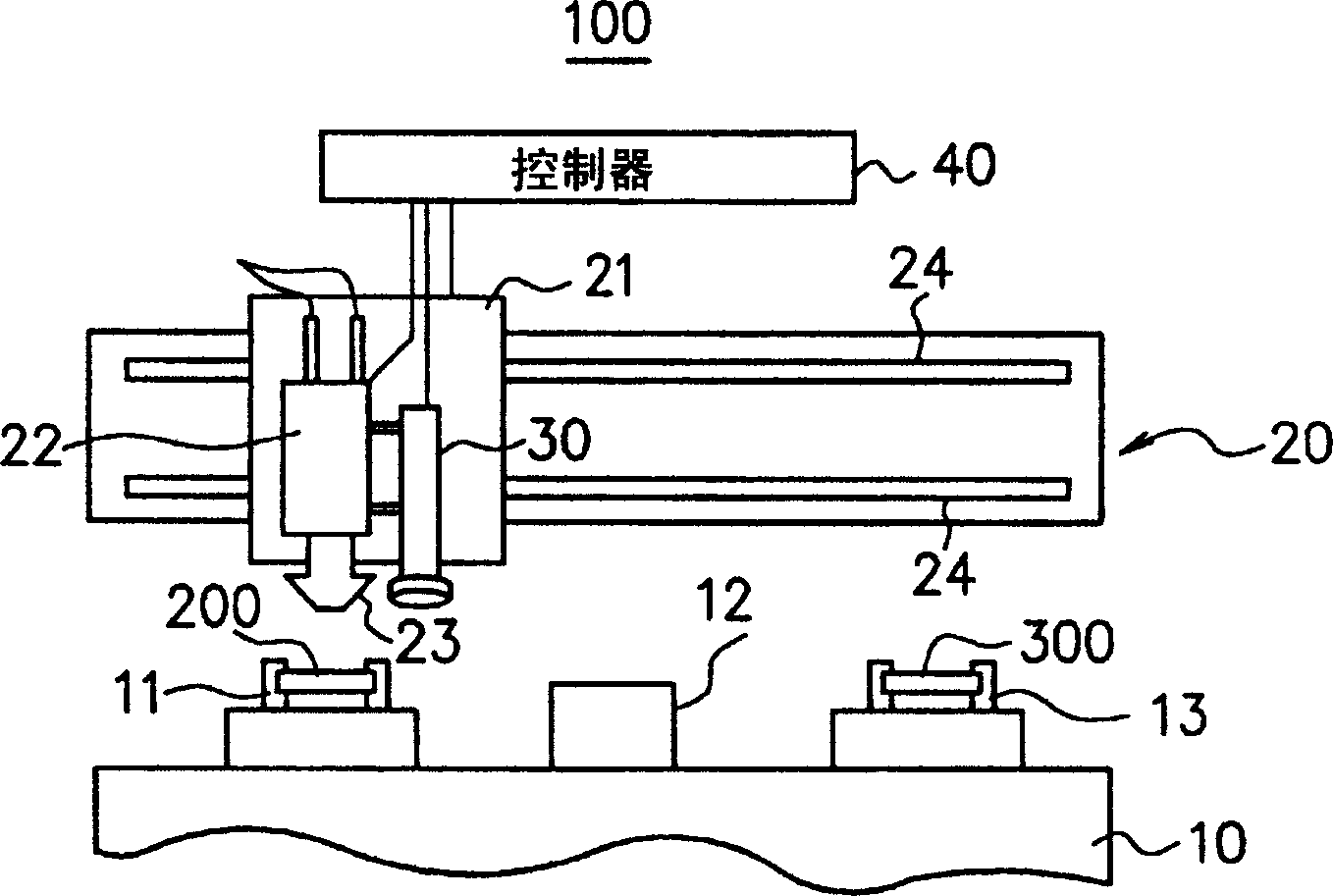

[0032] An embodiment of the present invention will be described below with reference to the accompanying drawings. figure 1 It is a figure which shows the schematic structure example of the circuit board conveyance apparatus of this embodiment. Such as figure 1 As shown, the circuit board transfer device 100 of this embodiment has a base 10 , a moving mechanism 20 , a camera 30 , and a controller 40 .

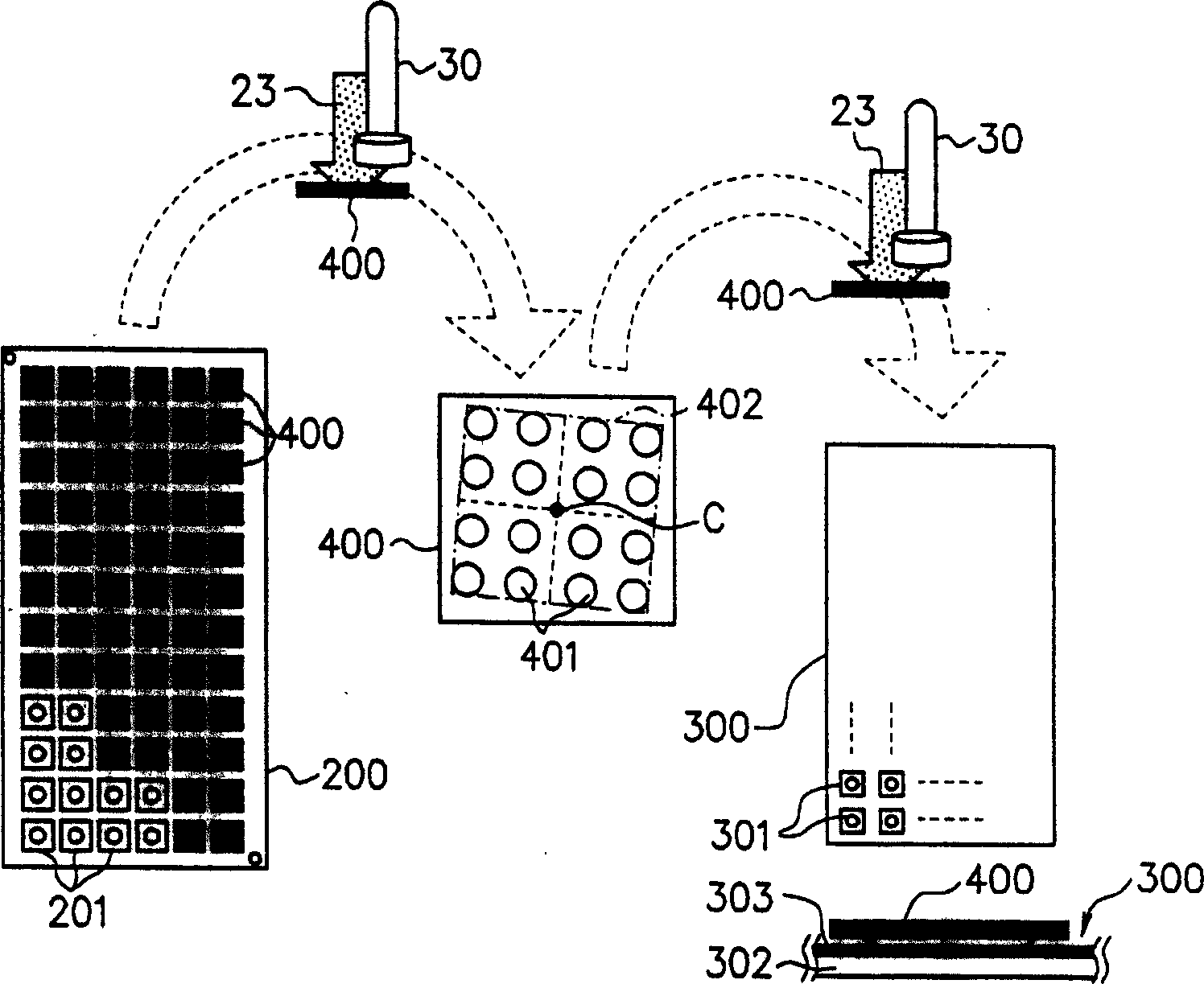

[0033] On the base 10, a tray support 11, an imaging stand 12, and a carrier support 13 are provided. The tray holder 11 is a member that holds a dedicated tray 200 for placing a plurality of circuit boards (for example, CSP) of a BGA structure semiconductor package before mounting solder balls. On the BGA tray 200 , grid-shaped CSP storage portions are formed at substantially equal intervals, and a plurality of CSPs are placed on each CSP storage portion with the pad formation surface facing upward.

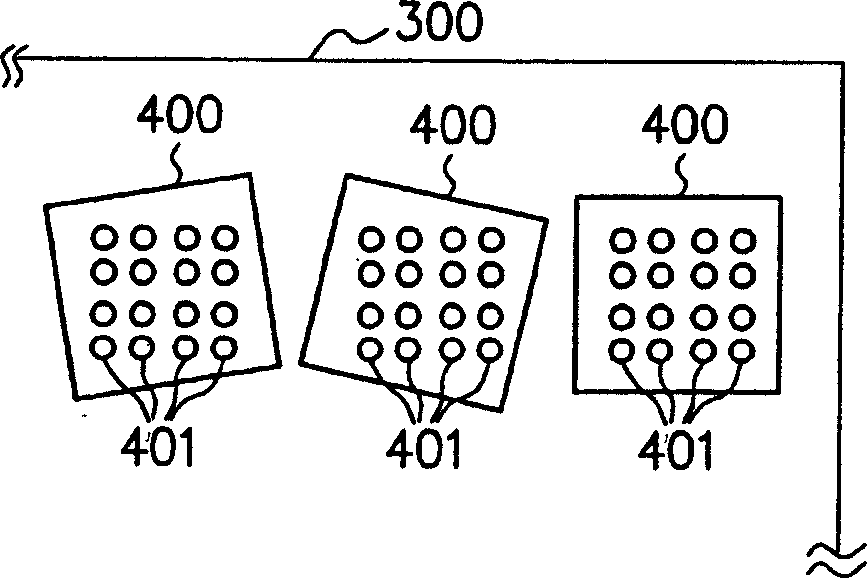

[0034] The imaging stage 12 is a stage for placing the CSP picked up fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com