Special multi-hole-site synchronous tapping machine for sill

A technology for tapping machines and sills, which is applied in the direction of thread cutting machines, positioning devices, metal processing machinery parts, etc., can solve the problems of slow time, difficult to guarantee processing accuracy, and inability to fully meet the processing volume, so as to improve production accuracy, adjust The effect of high processing quality, reducing labor intensity and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

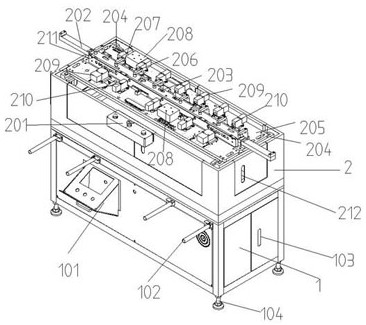

[0021] see figure 1 , the embodiment of the present invention includes:

[0022] A multi-hole synchronous tapping machine dedicated to the sill, the multi-hole synchronous tapping machine dedicated to the sill includes: a workbench 2 and a control cabinet 1, the control cabinet 1 is arranged under the workbench 2, and the control cabinet 1 Adjustable feet 104 are arranged at the bottom; a working surface is arranged on the workbench 2, and a sill bracket 202 is fixedly installed at the middle position of the working surface, and a plurality of sill positioning pins 203 are arranged on the sill bracket 202, so that The two sides of the sill brack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com