Fixing device for pipeline butt joint pairing connection and pipeline butt joint method

A technology of fixing device and counterpart group, which is applied to auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of inconvenient operation, difficulty in high-altitude group alignment, and high construction cost, and achieves no potential safety hazards, wide application range, and construction. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments, but the present invention is not limited thereto.

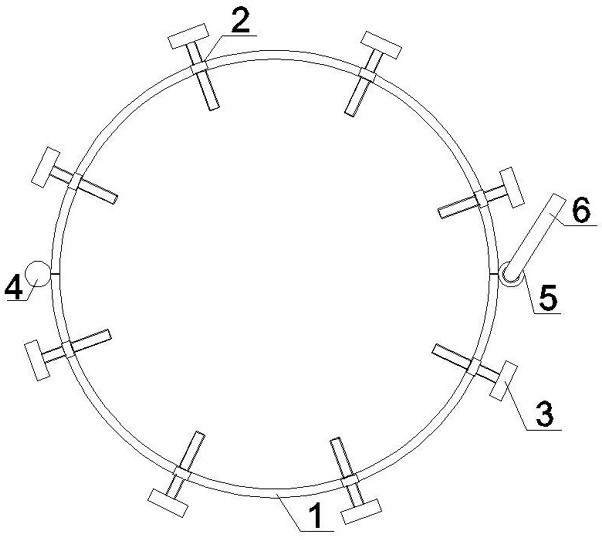

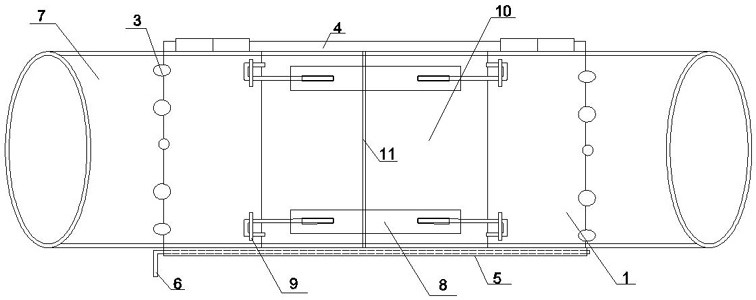

[0021] see figure 1 and figure 2 , a fixing device for the paired connection of pipelines provided by the present invention is composed of an arc hoop 1, a rotating shaft 4, an insertion rod 6 and an adjusting bolt 3, etc., the arc hoop 1 is a semicircular plate structure, two The arc hoop 1 constitutes a positioning tube structure. The two edges of the side wall of the arc hoop 1 are respectively fixed with rings 5, and the rotating shaft 4 is set in the ring 5 on one side, which is used to fix the two arc hoops 1 to rotate and open; the insertion rod 6 is inserted into the ring 5 on the other side , the pipeline 7 is temporarily fixed. Nut rings 2 are uniformly distributed on the upper and / or lower end faces of the arc-shaped hoop 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com