Intelligent tracking industrial robot base

An industrial robot and intelligent tracking technology, which is applied to manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as inability to intelligently track and cannot match different types of industrial robots, and achieve flexible and adaptable base devices strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

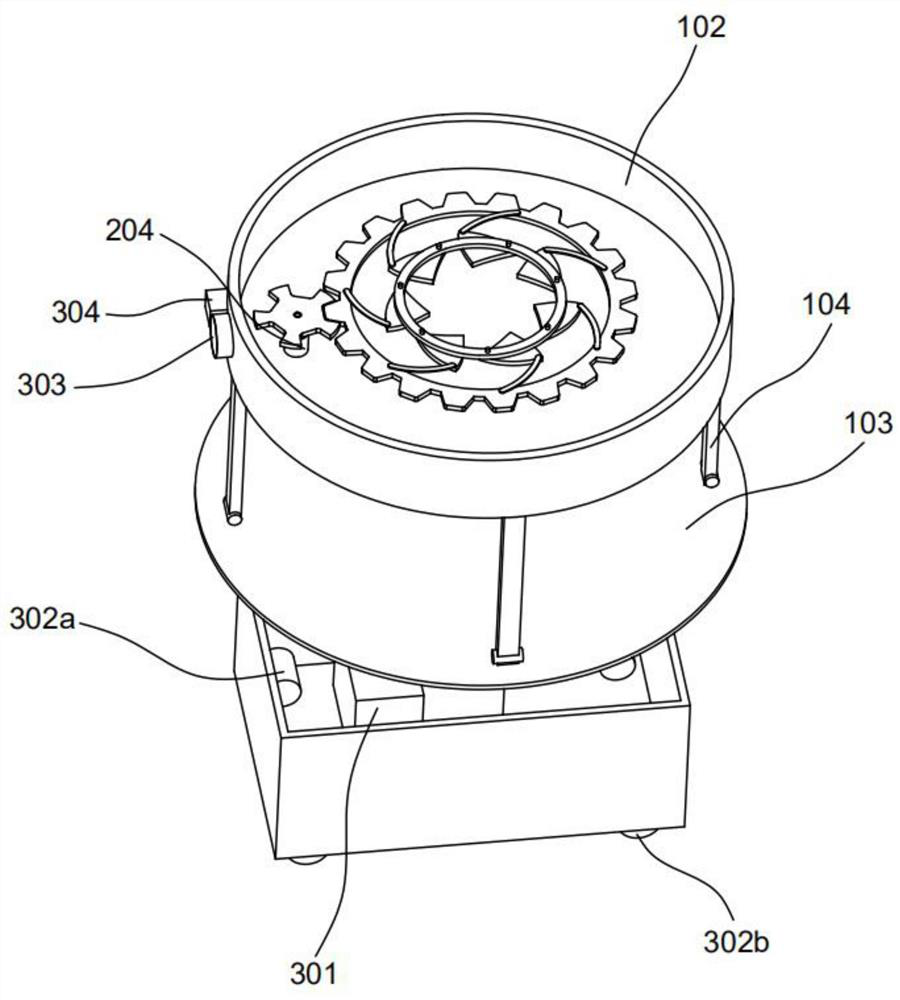

[0024] This embodiment provides a base for an intelligent tracking industrial robot, such as Figure 1-3 shown, including

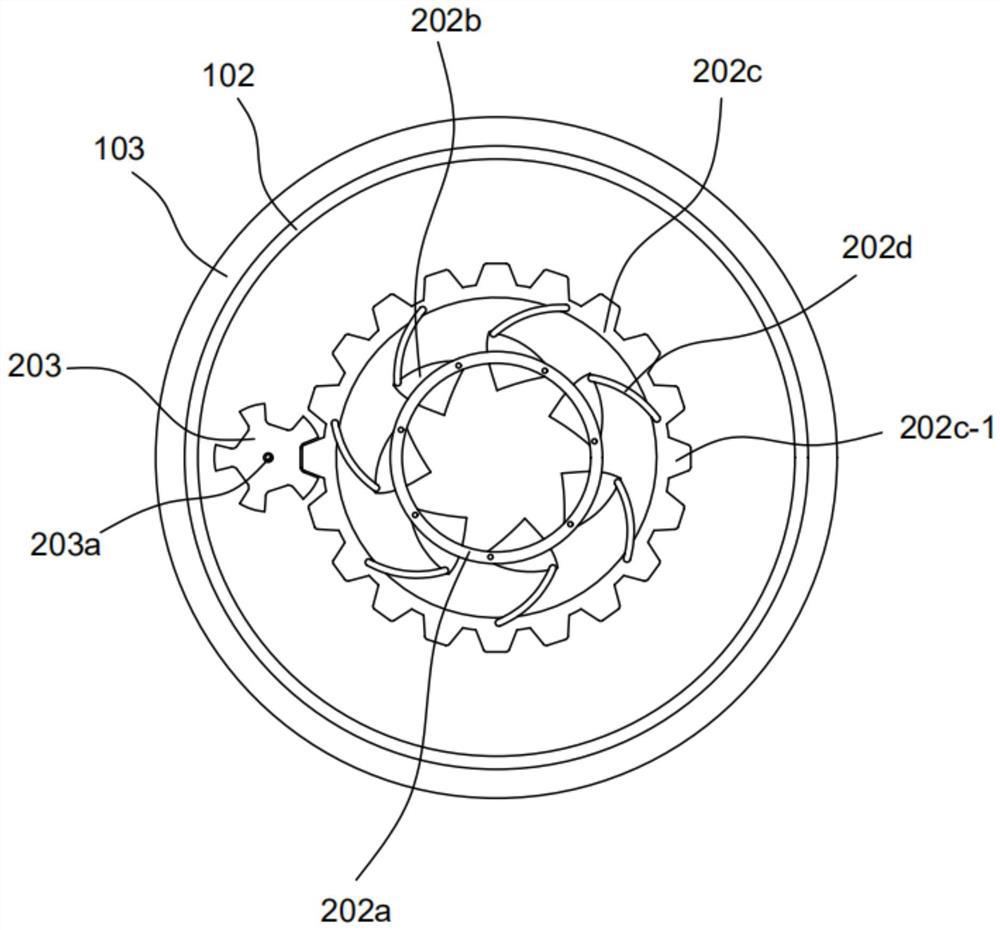

[0025] The outer casing 100 includes a lower casing 101 and an upper casing 102 arranged above the lower casing 101; Unit 202 ; and tracking module 300 , which includes a control unit 301 and a drive unit 302 arranged in the lower casing 101 , and also includes a camera 303 and an ultrasonic pan-tilt 304 arranged at the front end of the upper casing 102 .

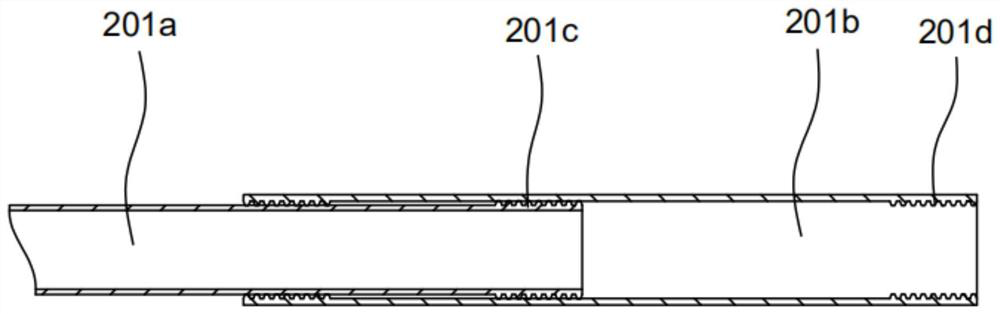

[0026] A tray 103 is arranged above the lower casing 101, and the telescopic unit 201 includes a connecting rod 201a arranged between the lower casing 101 and the tray 103. A sleeve 201b is sleeved on the outside of the connecting rod 201a, and the connecting rod 201a is slidably connected to the sleeve 201b. ; The end of the connecting rod 201a close to the sleeve 201b is circumferentially provided with an external thread 201c, and the inner side of the sleeve 201b is provided with a corresponding in...

Embodiment 2

[0031] This embodiment is different from the previous embodiment in that, as Figure 1-3 as shown,

[0032] The drive unit 302 includes a drive motor 302a arranged in the lower housing 101, and the outside of the drive motor 302a is connected with a wheel 302b; both sides of the front end of the lower housing 101 are also provided with obstacle avoidance modules 305; the control unit 301, the drive unit 302, the camera 303, An electrical connection is adopted between the ultrasonic pan-tilt 304 and the obstacle avoidance module 305 .

[0033]The control unit 301 includes a processor 301a; the processor 301a adopts an ATMEGA328p chip, which can perform high-speed calculations on the collected signals, and has high internal integration precision, which can completely omit traditional complex circuits, and has dynamic power consumption inside the chip. function, which allows the device to achieve a current consumption as low as 238μA in the running mode. The chip has a large-cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com