Forming process of double-cavity tube and double-cavity tube

A molding process and cavity tube technology, applied in the direction of catheters, hollow probes, etc., can solve the problem that the effective area of the cavity is difficult to fully utilize, and achieve easy molding quality control, high cavity utilization rate, and large effective utilization area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

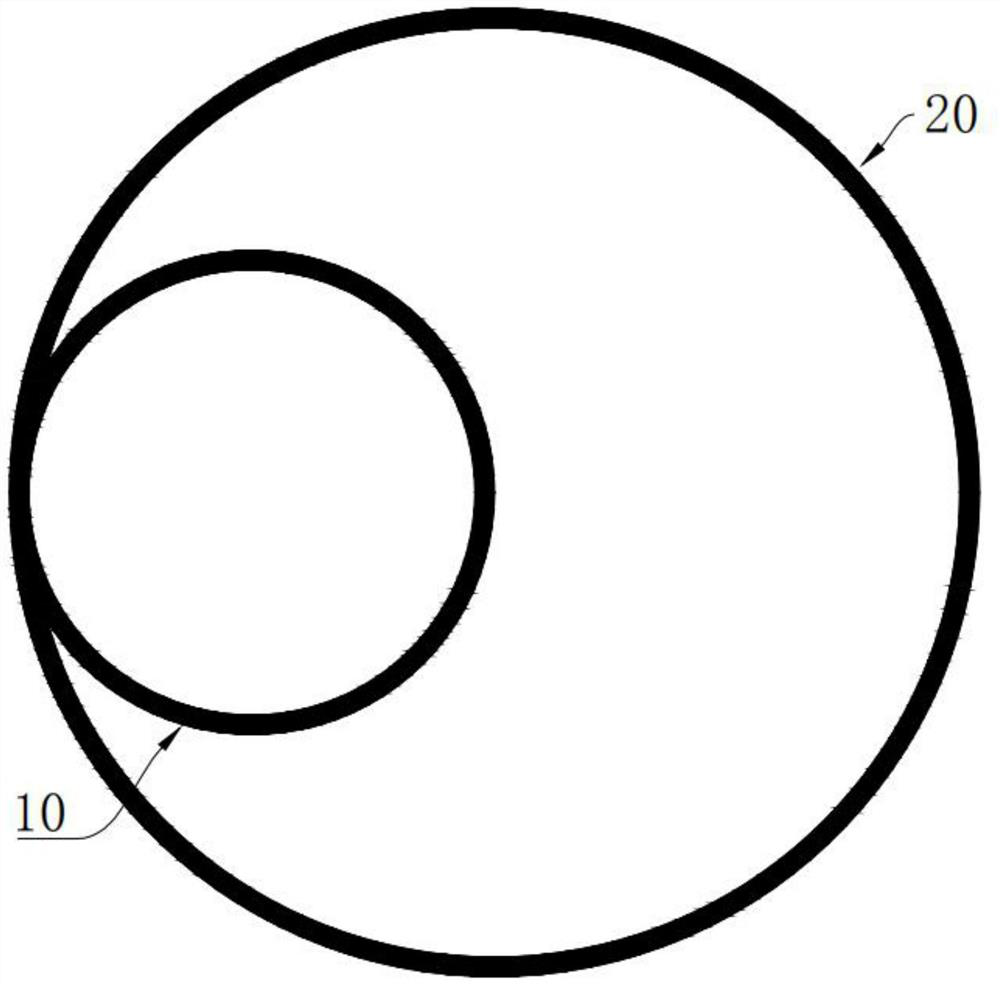

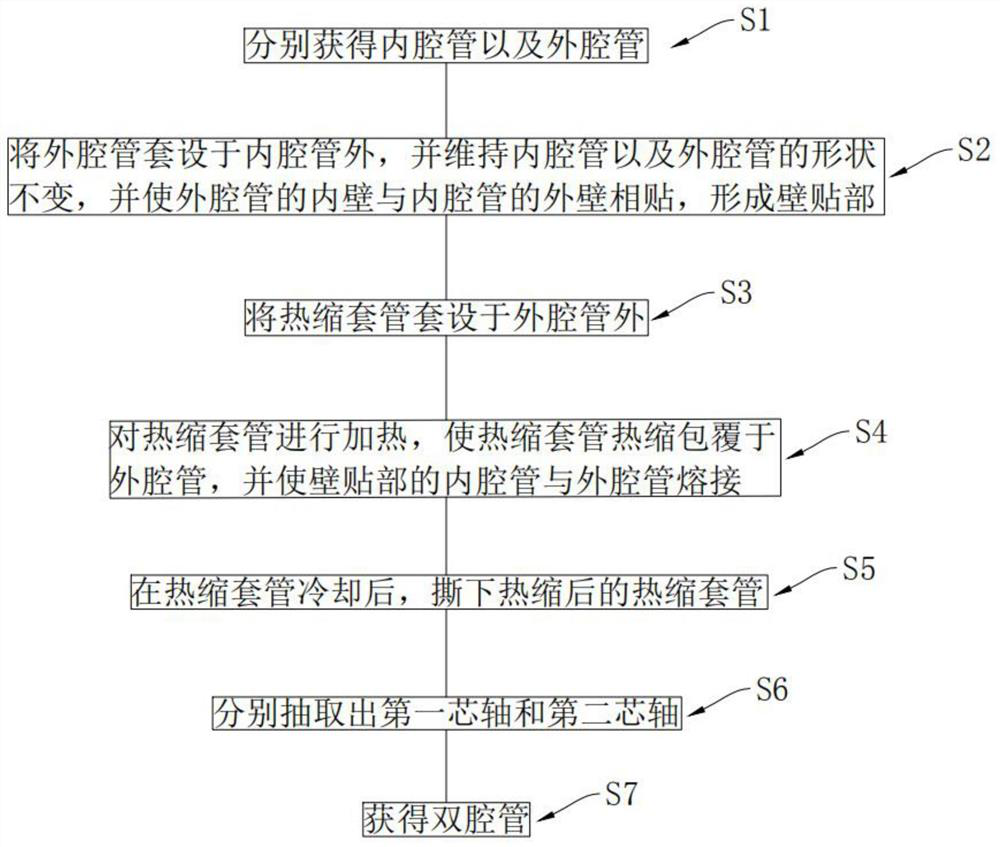

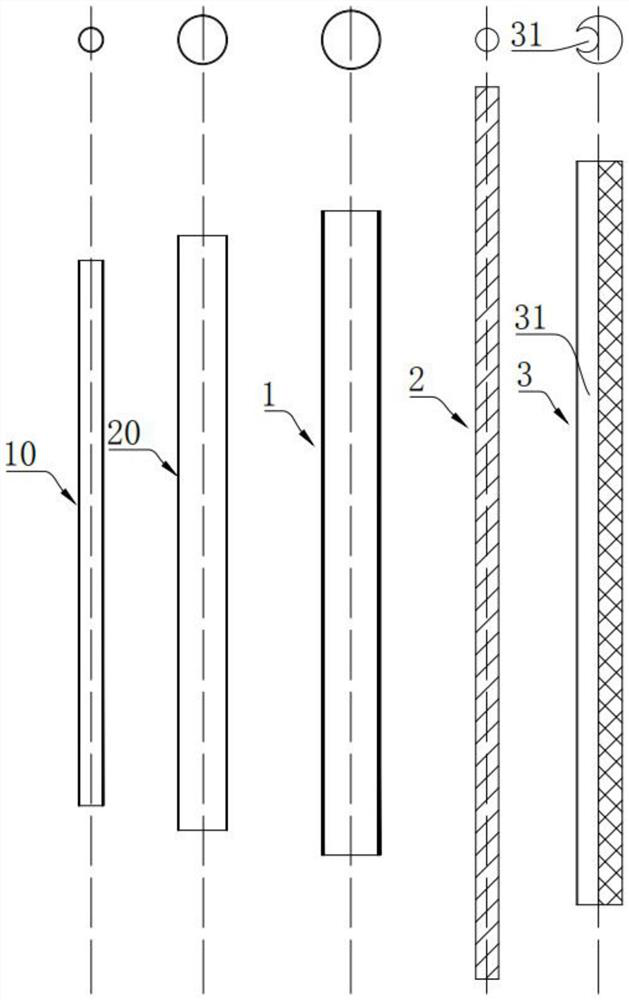

[0068] The molding process of the double-lumen tube in the embodiment itself is different from the first embodiment in that: in step S4, the inner lumen tube 10 and the outer lumen tube 20 of the wall-adhesive part are welded, including:

[0069] The ends of the inner lumen tube 10 and the outer lumen tube 20 away from the wall sticking portion are not welded.

[0070] It can be understood that the inner lumen tube 10 and the outer lumen tube 20 of the double lumen tube can be respectively connected with external joints after molding. In this embodiment, the ends of the inner lumen tube 10 and the outer lumen tube 20 away from the wall-adhesive part are not welded, that is, the outer wall of the inner lumen tube 10 near the middle part of the wall-adhesive part and the inner wall of the outer lumen tube 20 are welded, and The outer wall of the inner lumen tube 10 and the inner wall of the outer lumen tube 20 at the opposite ends of the wall-adhesive portion are not welded, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com