Paper gilding press

A bronzing machine, paper technology, applied in printing presses, rotary presses, printing and other directions, can solve the problems of long time, unfavorable production efficiency, cumbersome operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings. As a limitation of the present invention.

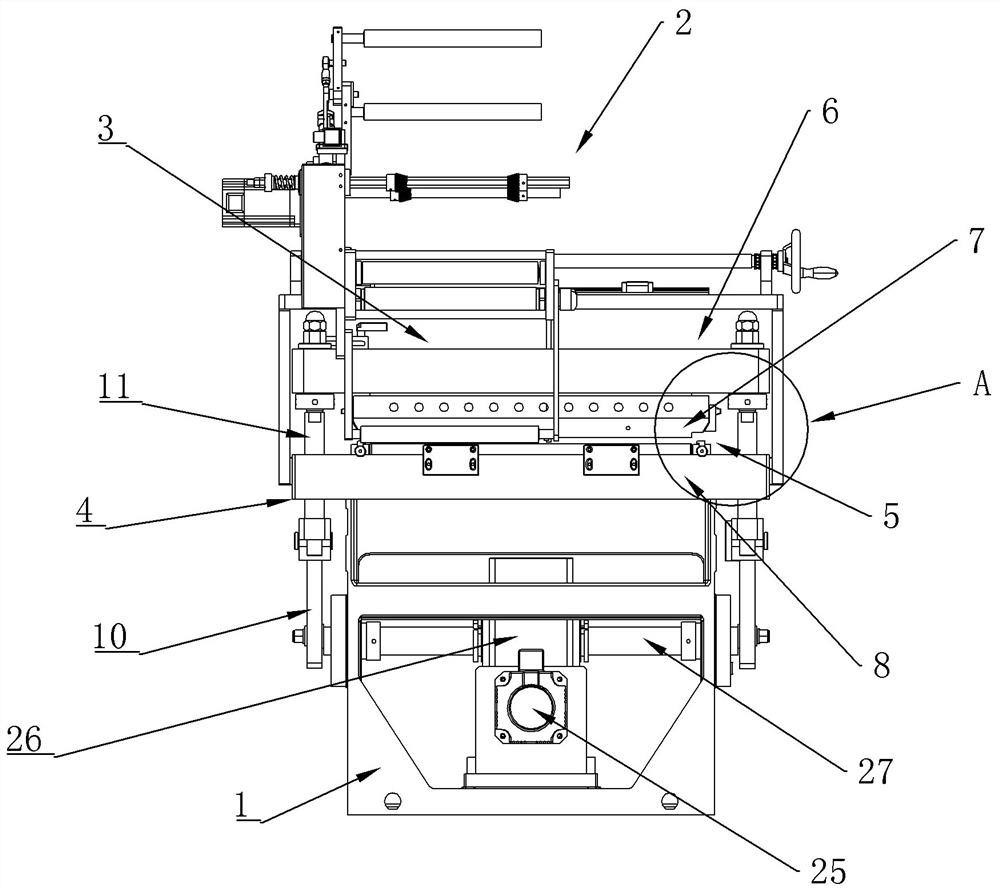

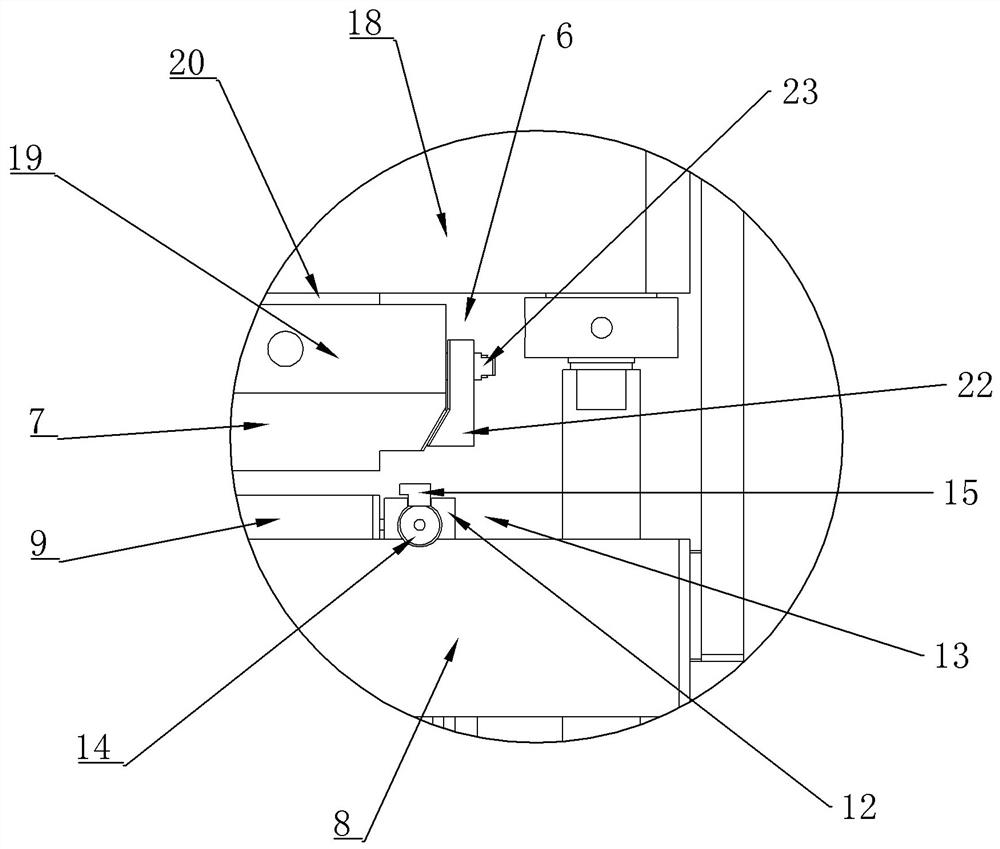

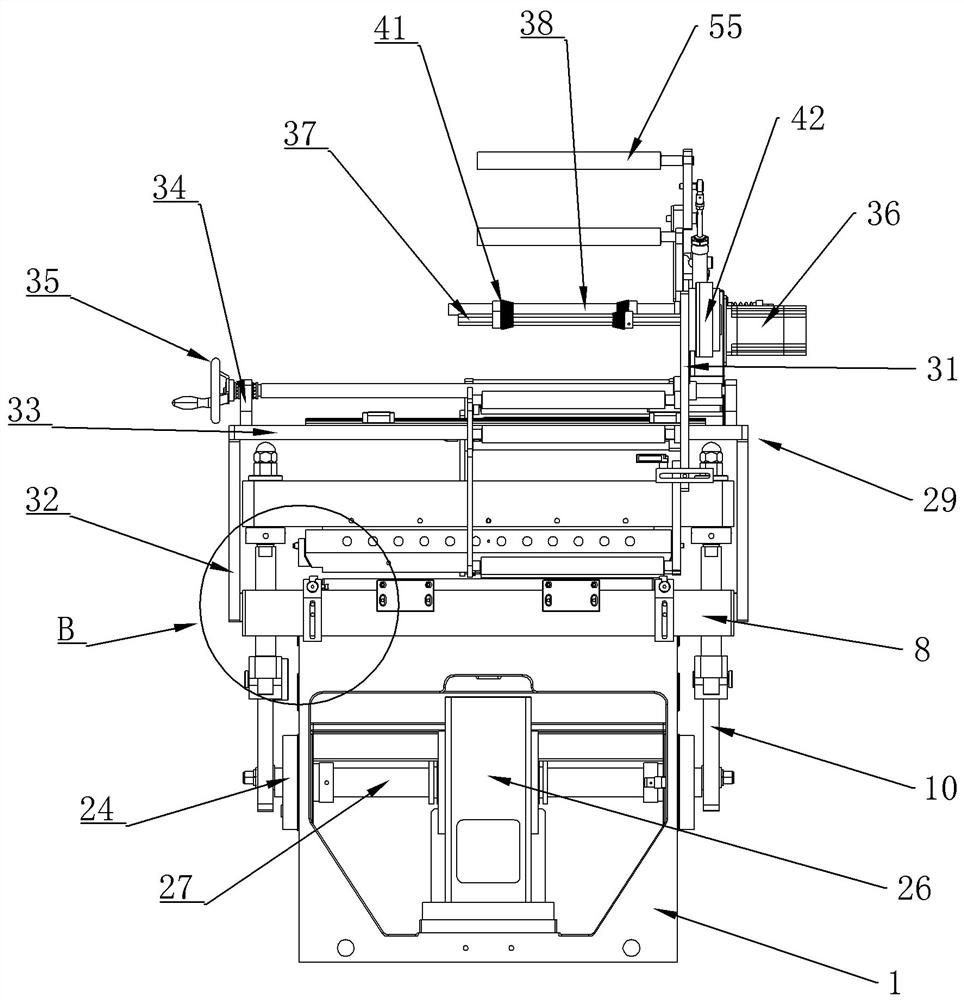

[0029] Figure 1-Figure 9 It shows the specific mechanism of a paper bronzing machine in an embodiment of the present invention, including a base 1, an aluminum foil driving mechanism 2 arranged on the base 1, an upper mold mechanism 3 and a lower mold mechanism 4 that cooperate with each other, and a die Replace the auxiliary mechanism 5; wherein, the upper mold mechanism 3 includes an upper mold base 6 and a die 7, and the die 7 is movable under the upper die base 6 through a clamping assembly; the lower die mechanism 4 It includes a lower mold base 8 and a backing plate 9 located above the lower mold base 8; the two sides of the base 1 are provided with lifting seats 10, and the power rod 11 of the lifti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap