Multi-fulcrum vest bag and preparation method thereof

A vest bag and multi-pivot technology, applied in the vest bag field, can solve the problems of insufficient toughness of the vest bag, falling out of items, and easy force reduction, etc., achieving the effects of being comfortable to carry, not easy to tear and damage, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

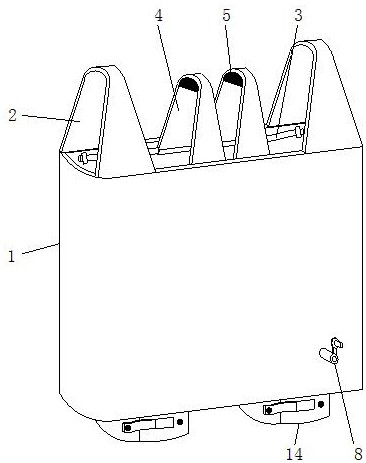

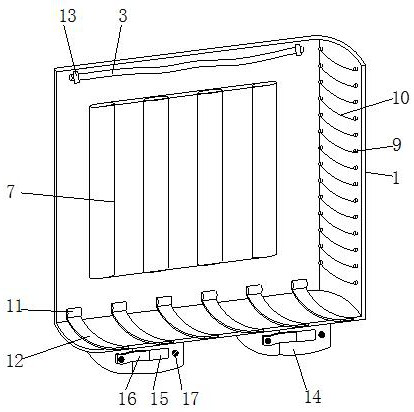

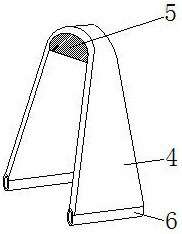

[0030] according to figure 1 , 2 , 3, and 4, the present embodiment proposes a multi-pivot vest bag, comprising a bag body 1, a first handle 2 and an elastic band 3, and both sides of the upper end of the bag body 1 are provided with a first handle 2 An elastic band 3 is provided above the front and rear ends of the inside of the bag body 1, and a second handle 4 is movably installed on the elastic band 3, and at least two groups of second handles 4 are provided, and the inner side of the second handle 4 The upper end of the upper end of the bag body is provided with a cushion 5, and both ends of the bottom of the second handle 4 are provided with sleeves 6, and the sleeves 6 are movably sleeved on the elastic band 3, and the front and rear ends of the inside of the bag body 1 are both An airbag cushion 7 is provided, and a valve core 8 is provided on the airbag cushion 7 , and the valve core 8 extends out of the bag body 1 . When in use, the second handle 4 is moved to the ...

Embodiment 2

[0036] according to Figure 5 As shown, the present embodiment proposes a kind of preparation method of multi-pivot vest bag, comprising the following steps:

[0037] Step 1: Prepare materials: rubber hose, rubber block, reinforcing fiber 10, elastic band 3, connecting belt 12, epoxy viscose, silver fiber, polypropylene fiber, polyurethane waterproof membrane, cotton fiber, tapioca flour, chitosan, Lignocellulosic and cornstarch;

[0038] Step 2: Put cassava flour, chitosan, wood fiber and cornstarch into the reaction kettle, mix evenly, add water to dilute at the same time, then stir and mix at 125°C to obtain a mixture, then heat and degas the mixture, Then use a twin-screw extruder to polycondense the mixture on the extruder to obtain the base material;

[0039]Step 3: Add cotton fiber, silver fiber and polypropylene fiber to the base material, stir evenly to obtain a mixture, and then introduce the mixture into a film blowing machine to obtain a film material, and then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com