Film feeding device of sheet ironing machine

A film feeding device and film feeding technology are applied in the decoration, transportation and packaging of textiles, textiles and papermaking, etc., and can solve the problems of not improving the tension of the film belt, increasing the tension of the film belt, and slipping the film belt. and other problems, to achieve the effect of improving the guiding and conveying efficiency, avoiding pulling deformation, and reducing the traction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

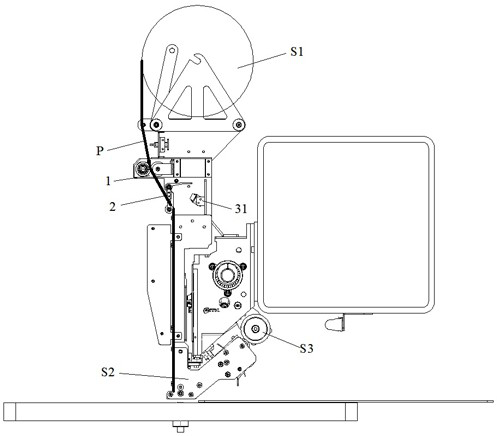

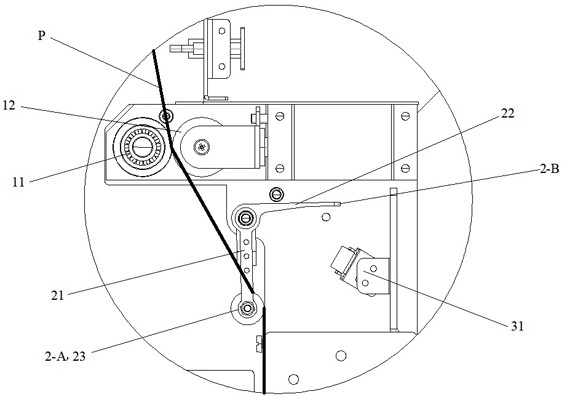

[0036] refer to figure 1 , figure 2 , a film feeding device of a hot sheet machine, which is arranged between the film tape reel S1 of the hot sheet machine and the stamping seat S2, which includes an active film feeding mechanism 1, a swing structure 2, and an induction system. The active film feeding mechanism 1 includes a film feeding mechanism located at The driving roller 11, the driven roller 12, and the drive motor for driving the driving roller 11 under the film tape reel S1, wherein the driving roller 11 and the driven roller 12 are respectively located on both sides of the film belt P, and the two are attached to the film On both sides of the tape P, start the driving motor to drive the driving roller 11 to rotate, drive the driven roller 12 to pull the film tape P, and pull and transport the film tape P on the film tape reel S1 to the stamping seat S2.

[0037] The swing structure 2 is located below the active film feeding mechanism 1 and can rotate on a fixed axi...

Embodiment example 2

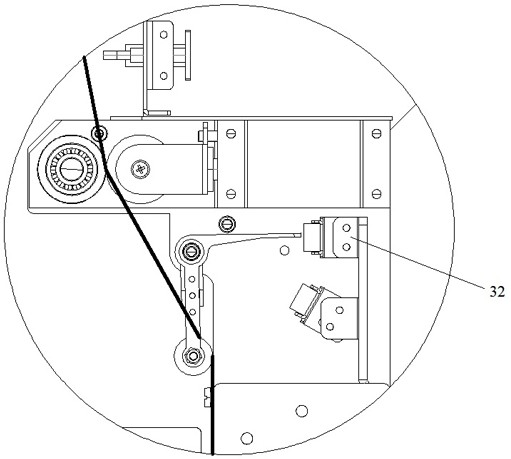

[0046] refer to image 3 and combine figure 1 , on the basis of implementing Case 1, the sensing system also includes a second sensor 32. After the active film feeding mechanism 1 is started, when the tension of the film belt P pulled and output by the active film feeding mechanism 1 reaches the minimum threshold, the second sensor 32 senses the second contact end 2-B and sends a stop signal to the active film feeding mechanism 1. The minimum threshold of the tension of the film belt P is also set according to the actual application situation. Usually, the first swing arm 21 and the second swing arm 22. The tension of the corresponding membrane tape P is set as the lowest threshold when it falls naturally.

[0047] Compared with the implementation case 1, if the active film feeding mechanism 1 allows slippage, the control of the tension of the film belt P in the implementation case 2 is more precise.

Embodiment example 3

[0049] refer to Figure 4 , Figure 5 , Image 6 and combine figure 1 , is different from implementation case 1 and implementation case 2. There are multiple driven rollers 12 and swing structures 2, and the frame S4 of the ironing machine is installed side by side with multiple driven rollers 12 and multiple swing structures along its translation direction. 2. To correspond to a plurality of film tapes P, the casing S5 or the main beam S6 of the ironing machine is equipped with an induction system, which is used to sense the second contact end of the swing structure 2 corresponding to the film tape P currently being punched. A plurality of said induction systems are installed side by side along the translation direction of the frame S4 of the ironing machine to correspond to a plurality of swing structures 2 .

[0050] Each driven roller 12 is equipped with a supporting mechanism 4, and the supporting mechanism 4 includes a supporting rod 41, a mounting frame 42, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com