Chemical vapor deposition method for preparing silicon carbide composite coating on single crystal silicon or polycrystalline silicon

A technology of chemical vapor deposition and composite coating, which is applied in the direction of coating, gaseous chemical plating, metal material coating technology, etc., can solve the problems of poor bonding between coating and substrate, thermal expansion coefficient mismatch, etc., to achieve good bonding, Dense structure, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the present embodiment, the chemical vapor deposition method of the silicon carbide composite coating is prepared on single crystal silicon is as follows:

[0036](1) The single crystal silicon substore is 50 min in deionized water and acetone, respectively, and then placed in hydrofluoric acid having a concentration of 5 wt%, and places the silicon base in the reaction chamber;

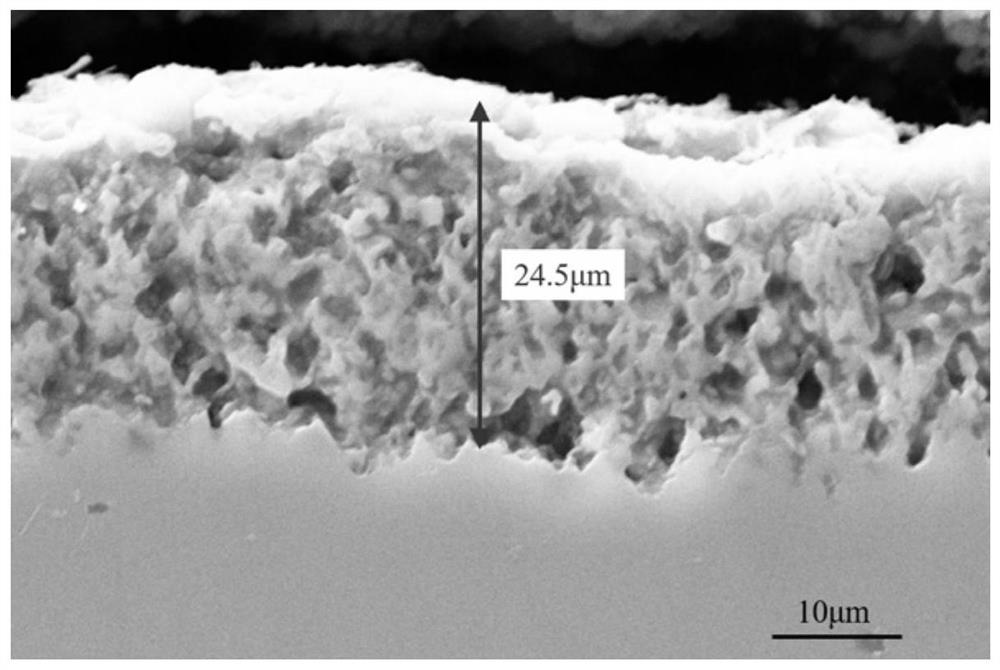

[0037] (2) Preparation of a porous silicon layer on a silicon substrate, an access H 2 And Ar, H 2 The flow rate is 200 sccm, the Ar flow is 1500 sccm, the etching temperature is 1200 ° C, the working pressure is 200 Pa, the etching time is 30 min, the thickness of the porous silicon layer is 24.5 μm, see figure 1 ;

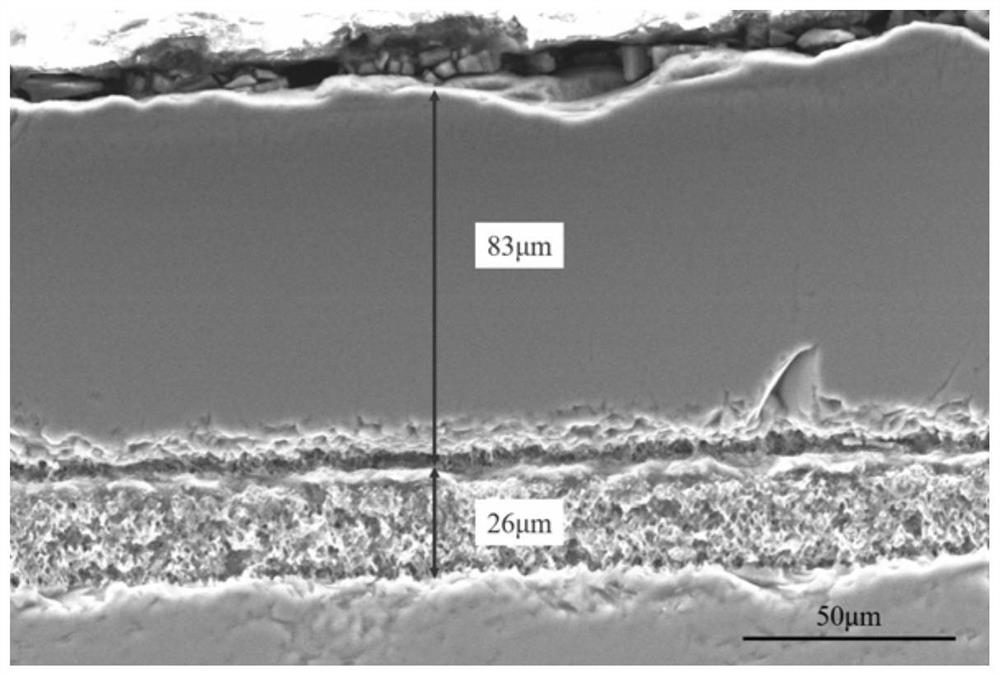

[0038] (3) Deposit a thin layer of SiOc buffer layer on the porous silicon layer, HMDSO liquid flow rate is 0.3 g / min, h 2 The flow rate of Ar is 200 Sccm, 3000 sccm, deposition temperature 1050 ° C, the working pressure is 300 Pa, deposition time 30 min, and the thickness of th...

Embodiment 2

[0044] In the present embodiment, the chemical vapor deposition method of the silicon carbide composite coating is prepared on the polysilicon is as follows:

[0045] (1) The polysilicon base is applied in deionized water and acetone, respectively, and then placed in hydrofluoric acid having a concentration of 5 wt%, placing the silicon substrate in the reaction chamber;

[0046] (2) Preparation of a porous silicon layer on a silicon substrate, an access H 2 And Ar, H 2 The flow rate 300sccm, the Ar flow rate is 3000 sccm, the etching temperature is 1250 ° C, the working pressure is 400 Pa, the etching time is 15 min, the thickness of the porous silicon layer is 12.5 μm;

[0047] (3) Deposit a layer of SiOC buffer layer on the porous silicon layer, HMDSO liquid flow rate is 0.6 g / min, h 2 The flow rate of Arccm, 5000 sccm, deposition temperature is 1100 ° C, the working pressure is 600Pa, the deposition time is 40 min, and the thickness of the buffer layer is 1.8 μm;

[0048] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com