A three-component side-by-side composite elastic staple fiber and its manufacturing method

A manufacturing method, three-component technology, applied in fiber processing, conjugated synthetic polymer rayon, filament/thread forming, etc., can solve the limitation of fiber elastic stretching freedom, component splitting and peeling, fiber crimping The problem of small quantity, etc., to achieve the effect of diversification of properties, high competitiveness, and improvement of uniformity of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

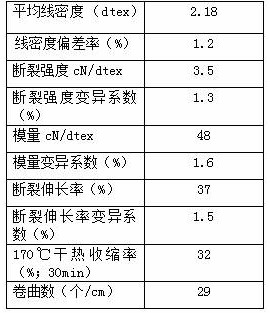

Embodiment 1

[0024] A manufacturing method of elastic composite fiber, comprising the steps:

[0025] Step A: Dry low-viscosity PET chips, high-viscosity PET chips, low-viscosity PTT chips, high-viscosity PTT chips, low-viscosity PBT chips, and high-viscosity PBT chips until the water content is less than 15 ppm, and the low-viscosity PET has a viscosity of 0.45dL / g, high viscosity PET viscosity is 0.85dL / g, low viscosity PTT viscosity is 0.51dL / g, high viscosity PTT viscosity is 1.0dL / g, low viscosity PBT viscosity is 0.48dL / g, high viscosity PBT viscosity is 0.89dL / g;

[0026] Step B: Separate modified PET chips (low viscosity PET chips and high viscosity PET chips), modified PTT chips (low viscosity PTT chips and high viscosity PTT chips), and modified PBT chips (low viscosity PBT chips and high viscosity PBT chips) Slices) are put into different three screw extruders for melt extrusion, and are metered into a special large-capacity three-component composite component through a meterin...

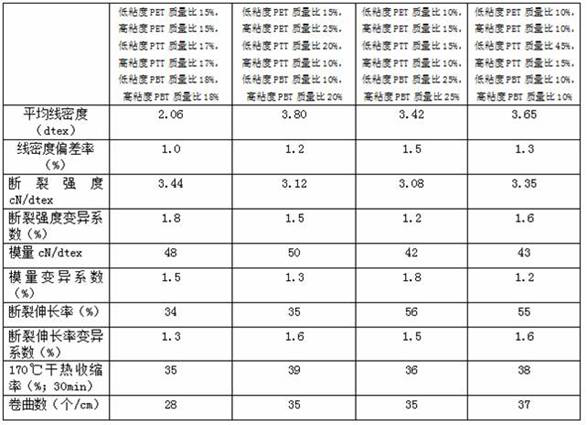

Embodiment 2-5

[0031] The mass ratios of low-viscosity PET chips, high-viscosity PET chips, low-viscosity PTT chips, high-viscosity PTT chips, low-viscosity PBT chips, and high-viscosity PBT chips are different. :

[0032]

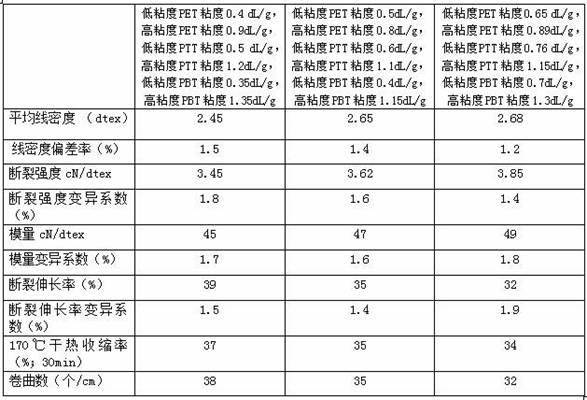

Embodiment 6-8

[0034] The viscosity of low-viscosity PET slices, high-viscosity PET slices, low-viscosity PTT slices, high-viscosity PTT slices, low-viscosity PBT slices, and high-viscosity PBT slices are different, and the preparation method is the same as Example 1, and the performance parameters of the obtained composite fibers are as follows:

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com