Process for preparing piezoelectric ceramic and polymer piezoelectric composite material

A technology of piezoelectric composite materials and piezoelectric ceramics, which can be used in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., and can solve the problems of poor bonding between two phases of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

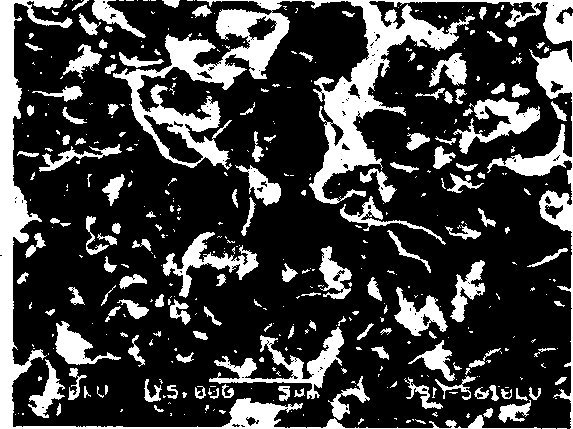

Image

Examples

Embodiment 1

[0015] Example 1: Mix 70% PZT and 30% PVDF powders by volume, and ball mill for 8 hours with absolute ethanol as the ball milling medium. After the mixture is dried, it is compressed into a mold, and then the compressed mixture is irradiated together with the mold. The microwave frequency is 2.45GHz, the irradiation power is 800W, and the irradiation time is 10 minutes. Piezoelectric ceramic-polymer composites. Tested at normal temperature and 1KHz, when the PZT volume content is 70%, the dielectric constant of the composite material is 105, and the piezoelectric constant is 52pC / N. The interface of the composite material is well bonded, which is beneficial to the polarization of piezoelectric ceramics and improves the electrical properties of the composite material.

Embodiment 2

[0016] Embodiment 2: 50% P (VDF-TrFE) and 50% PT powder are mixed by volume ratio, add dehydrated alcohol wet milling evenly, after drying, press molding in the mould, then the mixed material of pressing Microwave irradiation is carried out together with the mold, the microwave frequency is 2.45GHz, the irradiation power is 900W, and the irradiation time is 10 minutes, and the piezoelectric ceramic-polymer composite material is prepared. Tested at normal temperature and 1KHz, when the PT volume content is 50%, the dielectric constant of the composite material is 61, and the piezoelectric constant is 30pC / N.

Embodiment 3

[0017] Embodiment 3: 70% PE and 30% PCM powder are mixed by volume ratio, after drying, press molding in self-made mould, adopt VW1500 type frequency conversion microwave instrument to carry out microwave irradiation to the pressed mixture, microwave frequency is 6-18GHz, the irradiation power is 125W, and the irradiation time is 120 minutes, and the piezoelectric ceramic-polymer composite material is prepared. Tested at normal temperature and 1KHz, when the volume content of PCM is 50%, the dielectric constant of the composite material is 34, and the piezoelectric constant is 19pC / N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com