A method for improving the mechanical properties of carbon nanotube-reinforced magnesium-based composites

A technology of carbon nanotubes and composite materials, which is applied in the field of metal matrix composite material preparation, can solve the problems of insignificant improvement of mechanical properties of reinforced magnesium matrix composite materials, and achieves the advantages of solving poor interface bonding, improving interface bonding strength and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

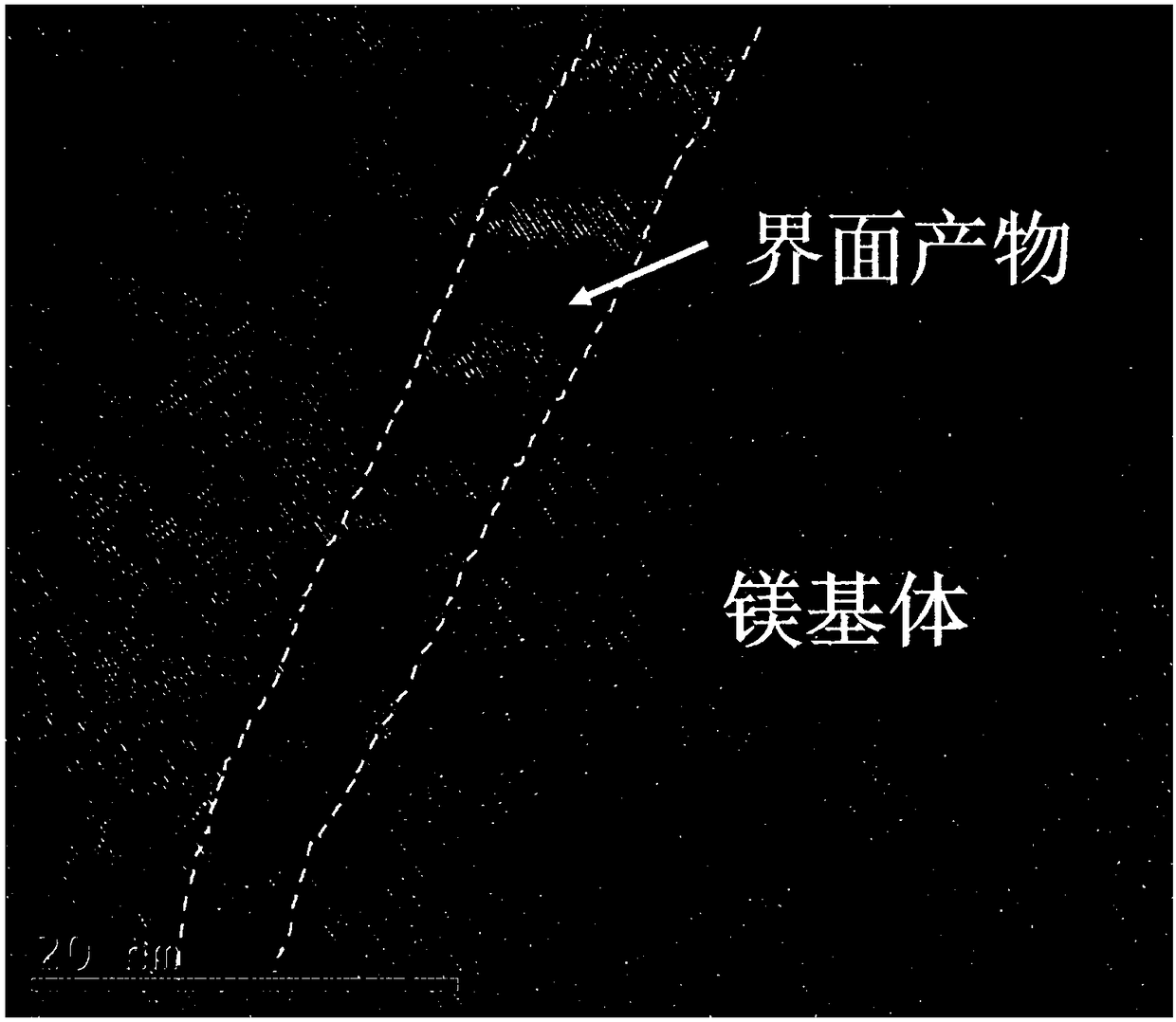

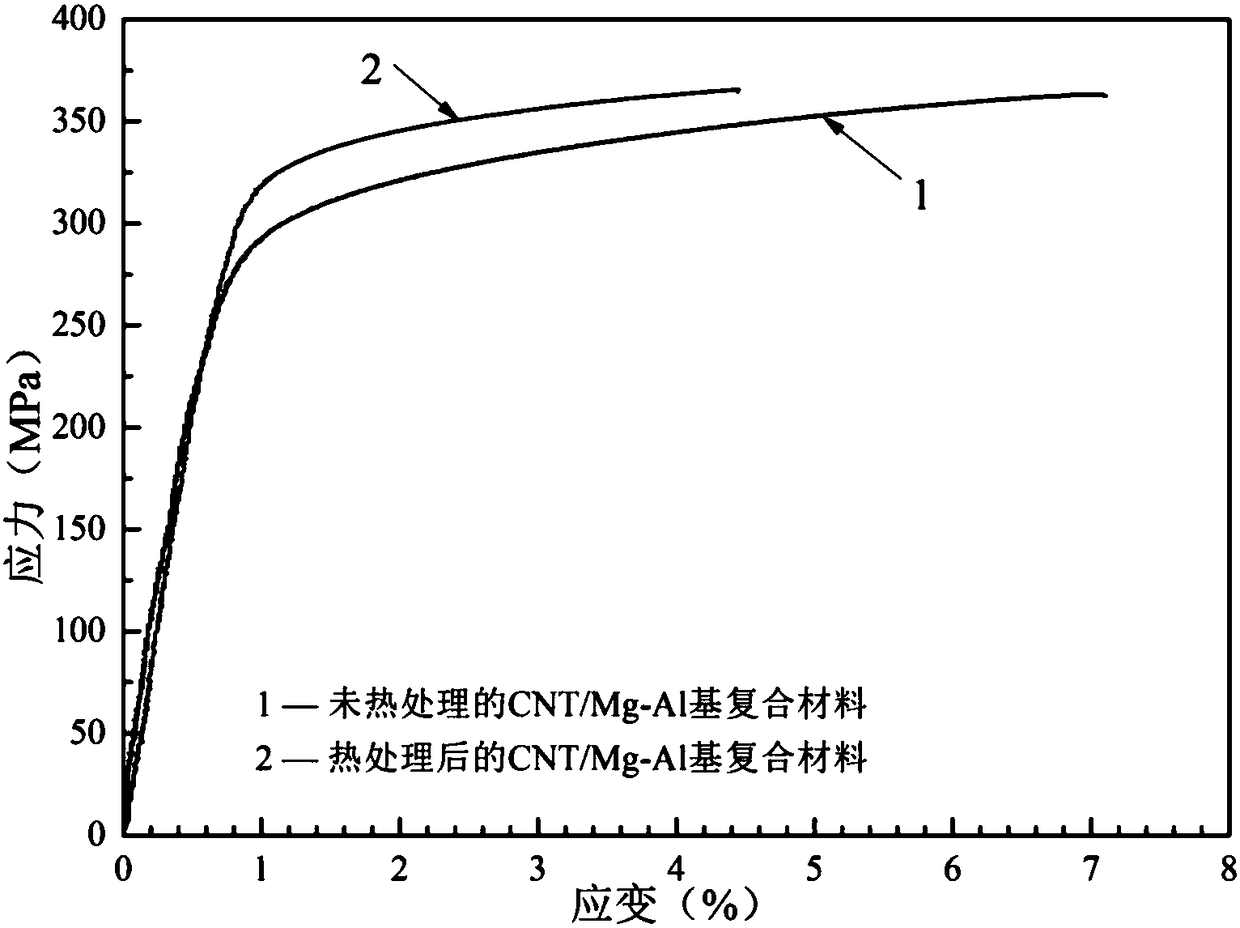

[0018] The process for improving the mechanical properties of carbon nanotube-reinforced Mg-Al composite materials prepared in this embodiment is carried out in the following steps. The prepared carbon nanotube-reinforced AZ91 containing 1.0wt.% CNTs (composition is 9.02wt.% Al, 0.65wt.% Zn, 0.22wt.% Mn, 0.05wt.% Si, the balance being Mg) the composite material block is put into heat treatment furnace, feeds the mixed gas of argon and hydrogen to protect (the proportion of hydrogen is : 0vol.%) protective gas, first set the heating rate to 10K / min to 500°C, then adjust the heating rate to 5K / min to 630°C, after holding for 5 hours, cool to room temperature with the furnace, and the performance is significantly improved Carbon nanotube-reinforced AZ91 composites.

Embodiment example 2

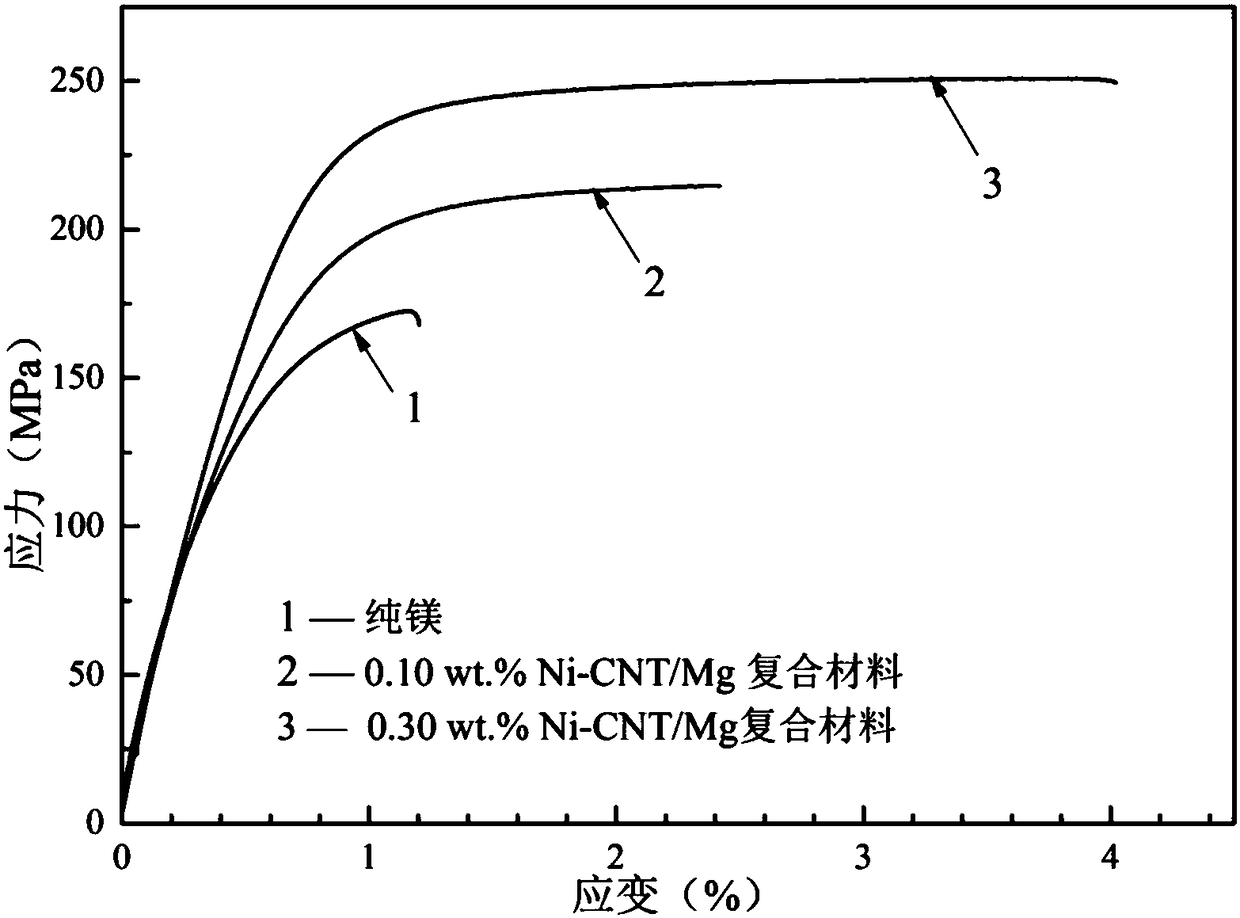

[0020] The process for improving the mechanical properties of carbon nanotube-reinforced pure magnesium-based composite materials prepared in this embodiment is carried out according to the following steps. The nickel-coated carbon nanotube-reinforced pure magnesium containing 0.1wt.% and 0.3wt.% CNTs respectively prepared The composite material blocks are put into the heat treatment furnace respectively, and the mixed protective gas of argon and hydrogen is introduced (the proportion of hydrogen is: 25vol.%). After h, take it out and cool it to room temperature in the air to obtain a carbon nanotube reinforced pure magnesium composite material with improved mechanical properties.

Embodiment example 3

[0022] The process for improving the mechanical properties of carbon nanotube-reinforced Mg-Al composite materials prepared in this embodiment is carried out in the following steps. The obtained carbon nanotube-reinforced AZ31 containing 5.0wt.% CNTs (composition is 3.10wt.% Al, 1.10wt.% Zn, 0.30wt.% Mn, 0.01wt.% Si, the balance is Mg) composite material blocks are put into heat treatment furnace, pass into the mixed protection gas of pure argon and hydrogen (the proportion that hydrogen occupies is : 10vol.%) protective gas, set the heating rate to 10K / min and raise the temperature to 500°C, after 120 hours of heat preservation, take it out and put it in water to quench to room temperature, and obtain the carbon nanotube reinforced AZ31 composite material with improved mechanical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com