Engineering waste gas emission device

A waste gas emission and engineering technology, applied in the direction of vertical pipelines, pipes/pipe joints/fittings, building components, etc., can solve the problems of inconvenient transportation, difficulty in pipeline transformation, large size, etc., and achieve novel structure and flexible laying methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

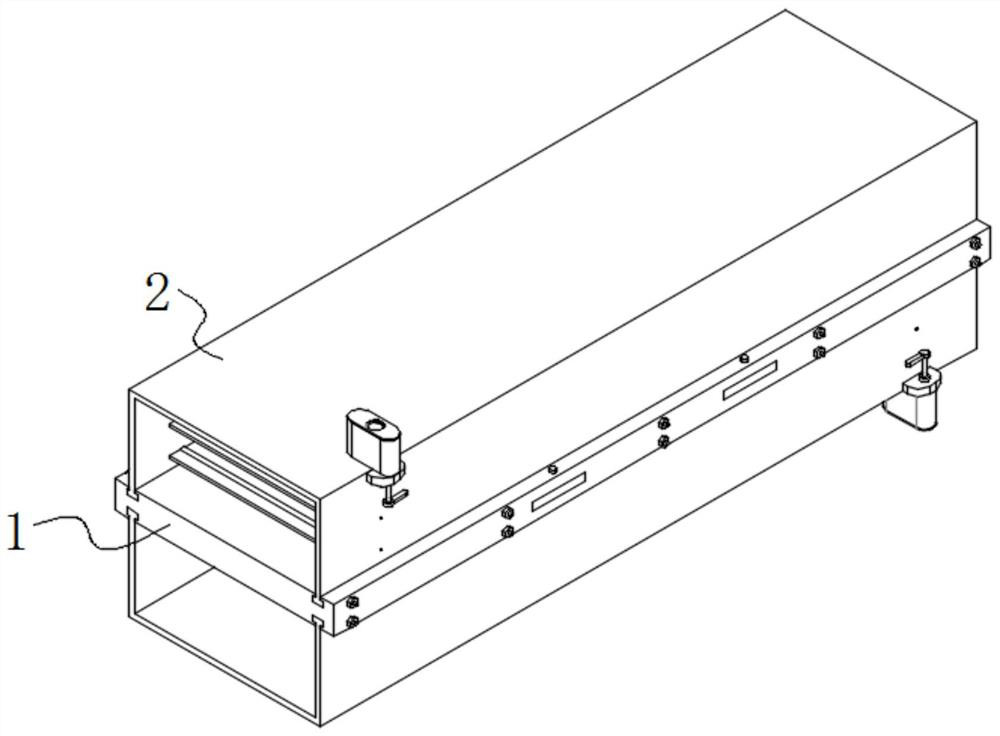

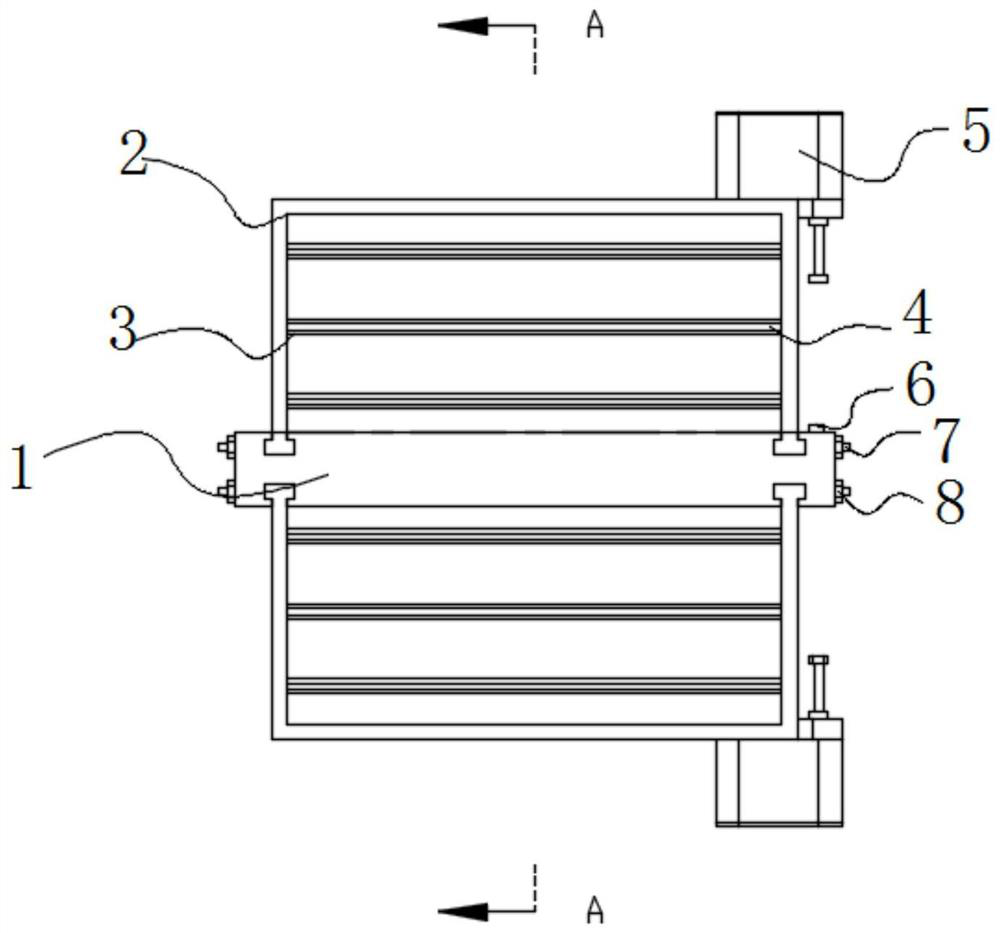

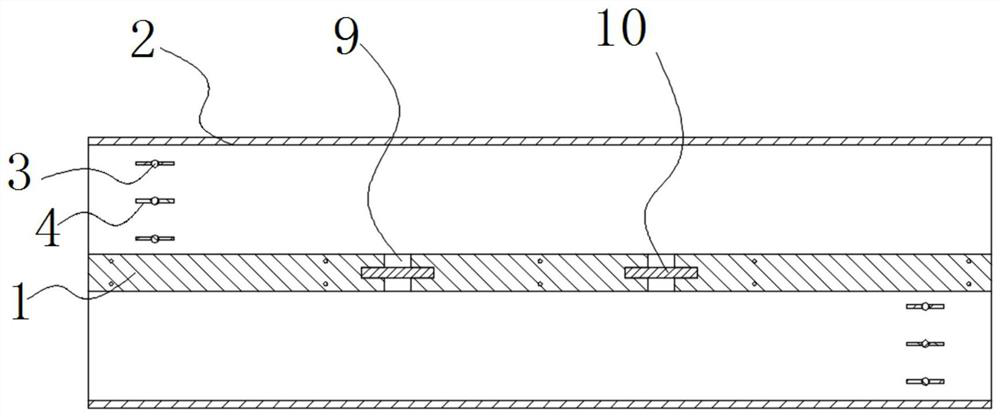

[0034] see Figure 1-12 As shown, the present invention is an engineering waste gas discharge device, including a substrate 1 and a housing 2;

[0035] Both the upper surface and the lower surface of the substrate 1 are provided with a plurality of installation grooves 11, the lower end of the housing 2 is slidingly connected with the installation grooves 11, and a plurality of matching holes 12 are opened on both sides of the housing 2, and the screw rods 7 and 7 are installed in the matching holes 12. Through the base plate 1, a number of nuts 8 are threaded on the side of the screw rod 7, and the nuts 8 are against the two sides of the base plate 1; , and then install the housing 2 on the upper and lower surfaces of the substrate 1 or one of the surfaces according to the requirements, thereby forming an exhaust gas duct. When the housing 2 only needs to be installed on one surface of the substrate 1, the other surface can be reserved for subsequent installation The housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com