Direct air cooling combined type atomizing back pressure reducing device

A back-pressure device and air-cooling technology, which is applied to steam engine devices, heating methods, air-conditioning systems, etc., can solve problems such as high cost and complex equipment, and achieve the effects of small investment, low water consumption, and reduced back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

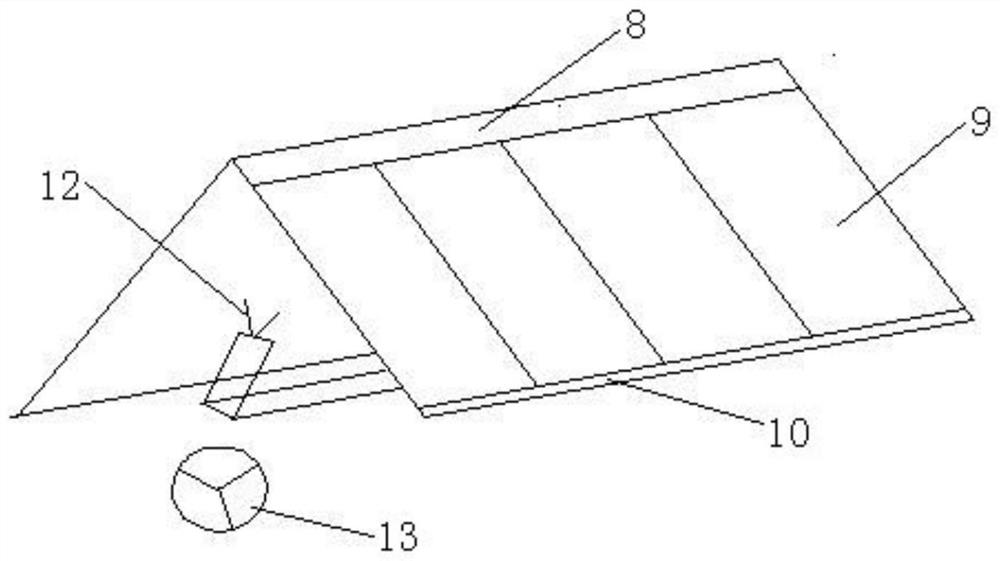

[0028] Taking a 300MW class direct air-cooled unit as an example to calculate, when the water spray temperature in the exhaust pipe is 35°C, the back pressure is 25kPa, and the ambient temperature is 35°C, the water spray in the exhaust pipe can reduce the back pressure by about 4kPa; Water spraying on the air side of the air-cooled island can reduce the ambient temperature by about 3.5°C. According to the performance curve of the air-cooled island, the back pressure can be reduced by about 4kPa. To sum up, this system can reduce the back pressure of about 8kPa for 300MW air-cooled units, and the effect is very obvious. It can ensure that the unit is fully loaded under the condition of finishing treatment without overheating in summer, which greatly reduces the operating pressure of the power plant. Avoid being assessed by the grid because of insufficient load.

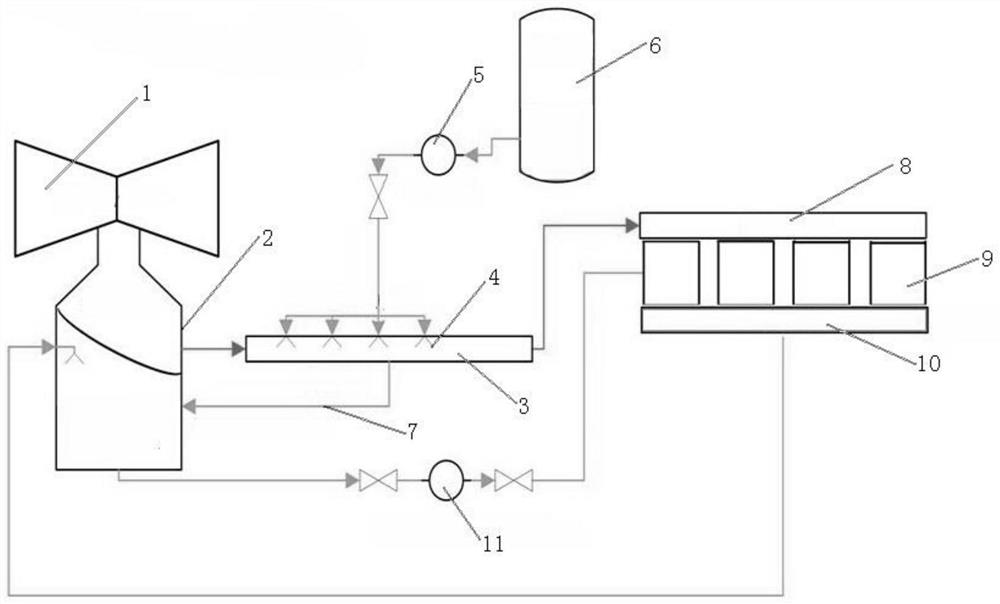

[0029] The present invention relates to a direct air-cooling combined spraying back pressure reducing device, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com