Prawn breeding device capable of improving breeding efficiency

A technology for raising seedlings and prawns, which is applied to the field of prawn seedlings raising equipment, can solve problems such as insufficient heat supply, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

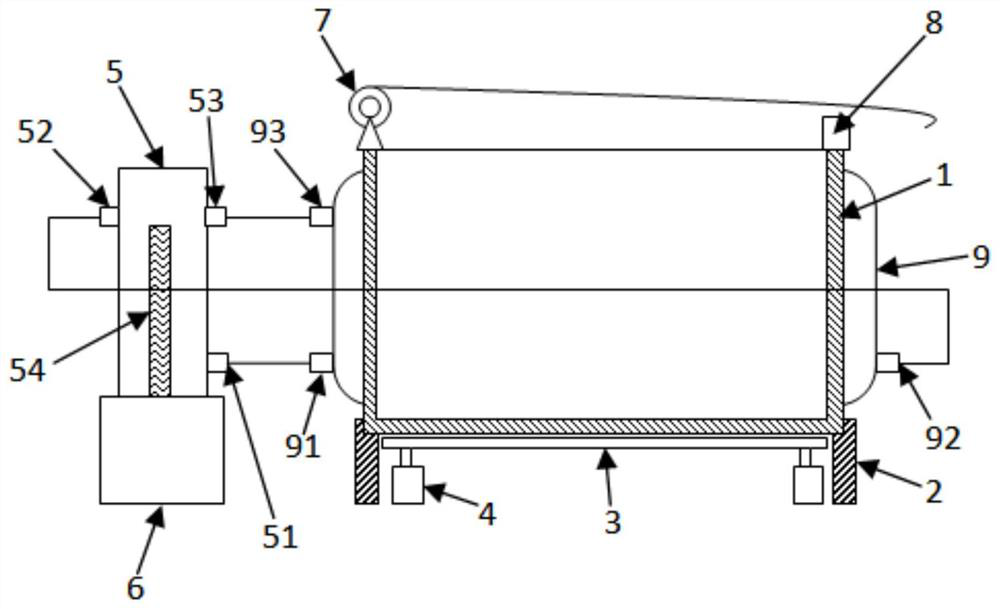

[0021] Such as figure 1 Shown, a kind of prawn nursery equipment that can improve nursery efficiency is characterized in that: it comprises plastic barrel, support, black plastic plate, cylinder, electric kettle and heat exchange jacket, and described plastic barrel is square, and plastic barrel material is Heat-conducting plastic, the outer periphery of the bottom of the plastic bucket is fixed by a bracket, and a cylinder is arranged on the ground below the plastic bucket, and a black plastic plate is installed on the top of the push rod of the cylinder. When the water temperature is low, the black plastic plate is pressed against The heat absorbed by the black plastic plate is directly transferred to the plastic barrel. When the water temperature is high, the black plastic plate is separated from the plastic barrel through the cylinder, and the heat absorbed by the black plastic plate is lost in the air; the plastic barrel is sleeved There is a heat exchange jacket, the wat...

Embodiment 2

[0027] A water temperature probe is installed in the plastic bucket, a processor is arranged in the fixed seat, the water temperature probe is connected to the signal of the processor, and the processor is respectively connected to the water pump at the water inlet and the water pump at the water outlet. When the natural light is not enough When the water temperature is guaranteed, the processor senses the water temperature through the water temperature probe. When the water temperature is lower than the set value, the processor starts the water inlet pump to add water to the heat exchange jacket until the water in the heat exchange jacket returns from the overflow port to the return port; After the water temperature is higher than the set value, the processor turns on the water pump at the water outlet and turns off the water pump at the water inlet, so that all the water in the heat exchange jacket flows back. The relatively automatic heat exchange system reduces the workload...

Embodiment 3

[0029] The power supply of the electric heating rod is compatible with solar panels and commercial power, and using solar panels to provide all or part of the electric energy can reduce energy consumption. Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com