Colloidal capsule embedded with micromolecular hydrophilic components and preparation method thereof

A hydrophilic, small-molecule technology, applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problems of low embedding rate, low loading capacity, poor stability, etc., and achieve good repeatability, enhanced structural performance, and preparation conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

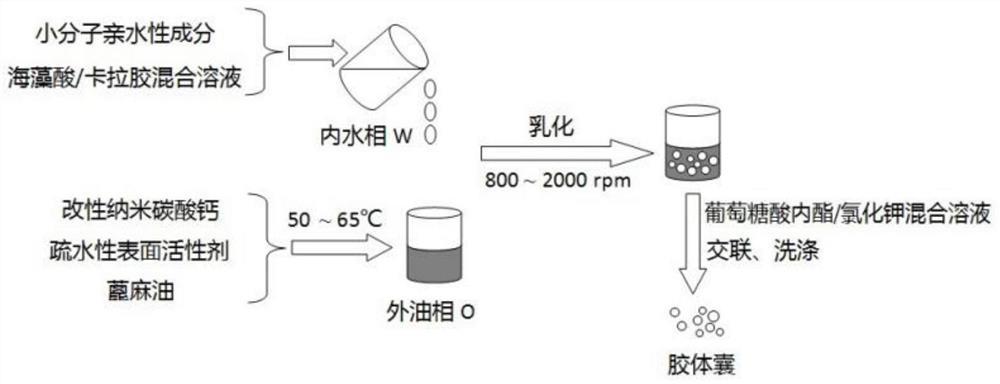

[0043] Such as figure 1 Shown, a kind of preparation method of the colloid capsule of embedding vitamin C comprises the steps:

[0044] (1) Add 0.1g alginic acid and 0.2g kappa-type carrageenan to 10g pure water, stir at room temperature to obtain a clear and transparent alginic acid / carrageenan mixed solution; add 2g vitamin C to 10g glacial acetic acid aqueous solution (0.2%, w / v), stirred at room temperature in the dark to obtain vitamin C solution;

[0045] (2) Add 0.1g of modified nano-calcium carbonate and 0.14g of Span 80 to 6.8g of castor oil respectively, and stir fully in a constant temperature water bath at 50°C to obtain a castor oil dispersion containing modified nano-calcium carbonate and Span 80 liquid;

[0046] (3) Add 2.2g alginic acid / carrageenan mixed solution dropwise to the castor oil dispersion containing modified nano calcium carbonate particles and Span 80 under stirring at 1500rpm, stir at 50°C for 10min, then add 0.5g vitamin C solution, continue t...

Embodiment 2

[0061] A preparation method for colloidal capsules embedding tea polyphenols, comprising the steps of:

[0062] (1) Add 0.25g of alginic acid and 0.1g of λ-type carrageenan to 10g of pure water, stir at room temperature to obtain a clear and transparent mixed solution of alginic acid / carrageenan; add 0.5g of tea polyphenols to 10g of ice Acetic acid aqueous solution (0.2%, w / v), stirring at room temperature in the dark to obtain a tea polyphenol solution;

[0063] (2) Add 0.15g of modified nano-calcium carbonate and 0.1g of Span 20 to 6.75g of castor oil respectively, and stir fully in a constant temperature water bath at 55°C to obtain a castor oil dispersion containing modified nano-calcium carbonate and Span 20 liquid;

[0064] (3) Add 2.2 g of alginic acid / carrageenan mixed solution dropwise to the castor oil dispersion containing modified nano-calcium carbonate particles and Span 20 under stirring at 1500 rpm, stir at 55° C. for 10 min, and then add 0.5g tea polyphenol ...

Embodiment 3

[0073] A preparation method for colloidal capsules embedding oligomeric proanthocyanidins, comprising the steps of:

[0074] (1) Add 0.15g of alginic acid and 0.2g of κ-type carrageenan to 10g of pure water, stir at room temperature to obtain a clear and transparent mixed solution of alginic acid / carrageenan; add 2.2g of oligomeric proanthocyanidins to 10g of ice Acetic acid aqueous solution (0.1%, w / v), stirring at room temperature in the dark to obtain an oligomeric proanthocyanidin solution;

[0075] (2) Add 0.12g of modified nano-calcium carbonate and 0.08g of polyglycerol castor oil to 6.75g of castor oil respectively, and stir fully in a constant temperature water bath at 52°C to obtain modified nano-calcium carbonate and polyglycerol castor oil Castor oil dispersion of alcohol esters;

[0076] (3) Add 2.2g alginic acid / carrageenan mixed solution dropwise to the castor oil dispersion containing modified nano-calcium carbonate particles and polyglycerol ricinoleate under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap