Motor painting device capable of saving raw materials

A technology of electric motors and raw materials, which is applied in the direction of electromechanical devices, manufacturing motor generators, and devices for coating liquid on the surface, etc. It can solve the problems of increased repair rate, resource waste, stator damage, etc., so as to achieve better addition of insulating varnish and reduction of resources The waste and the effect of reducing the repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

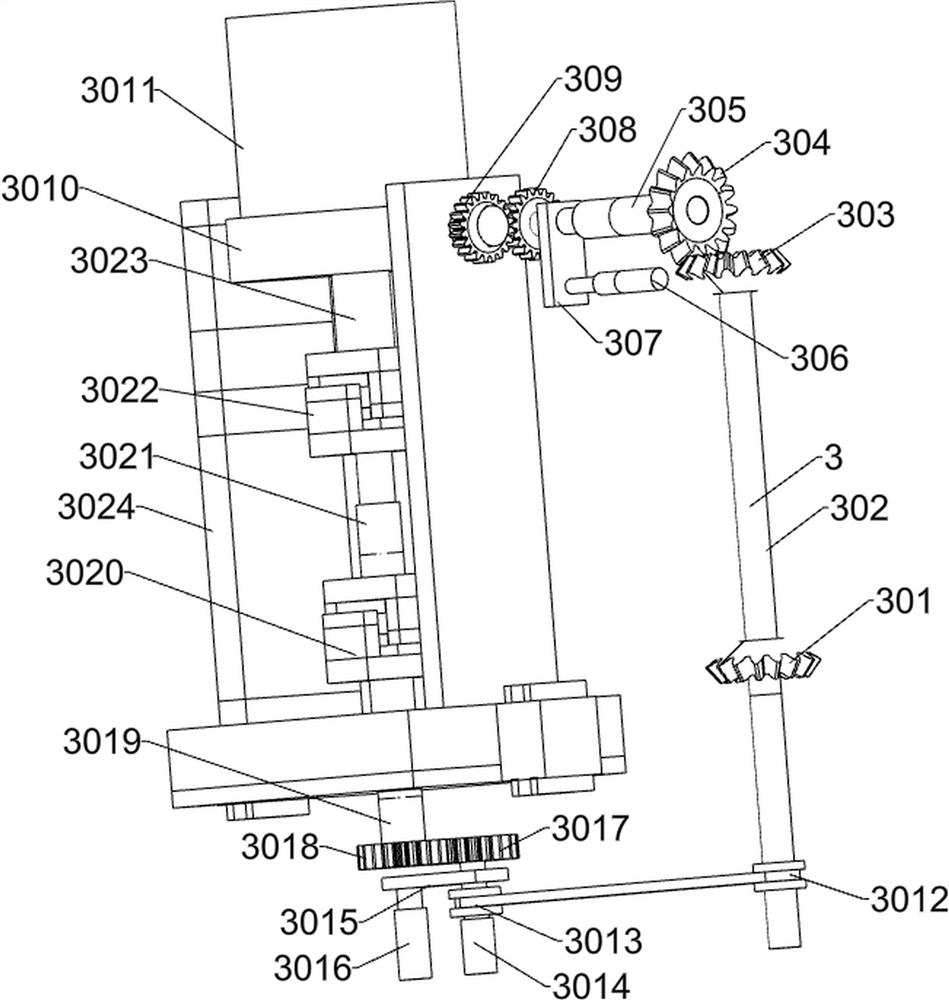

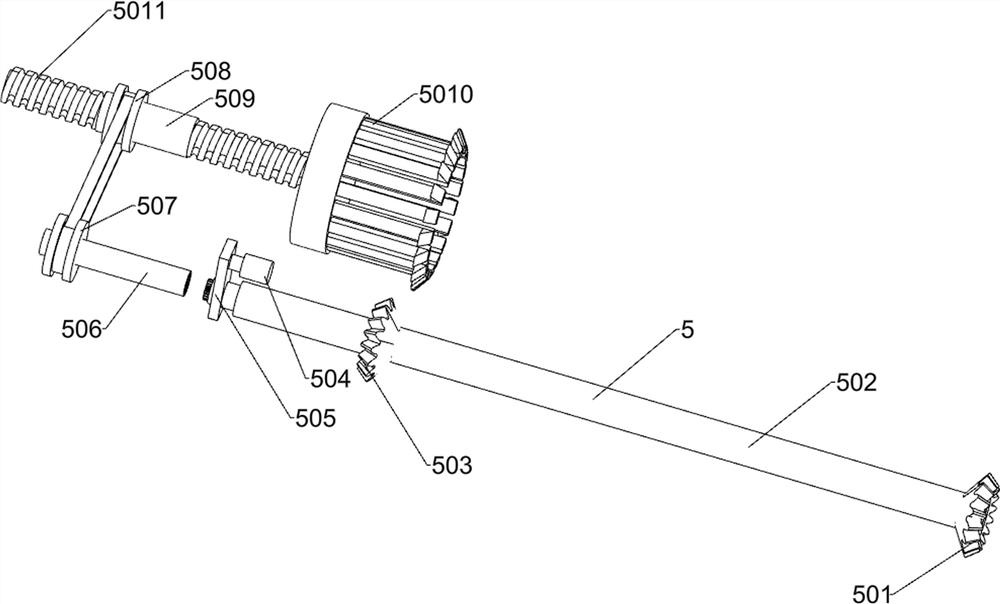

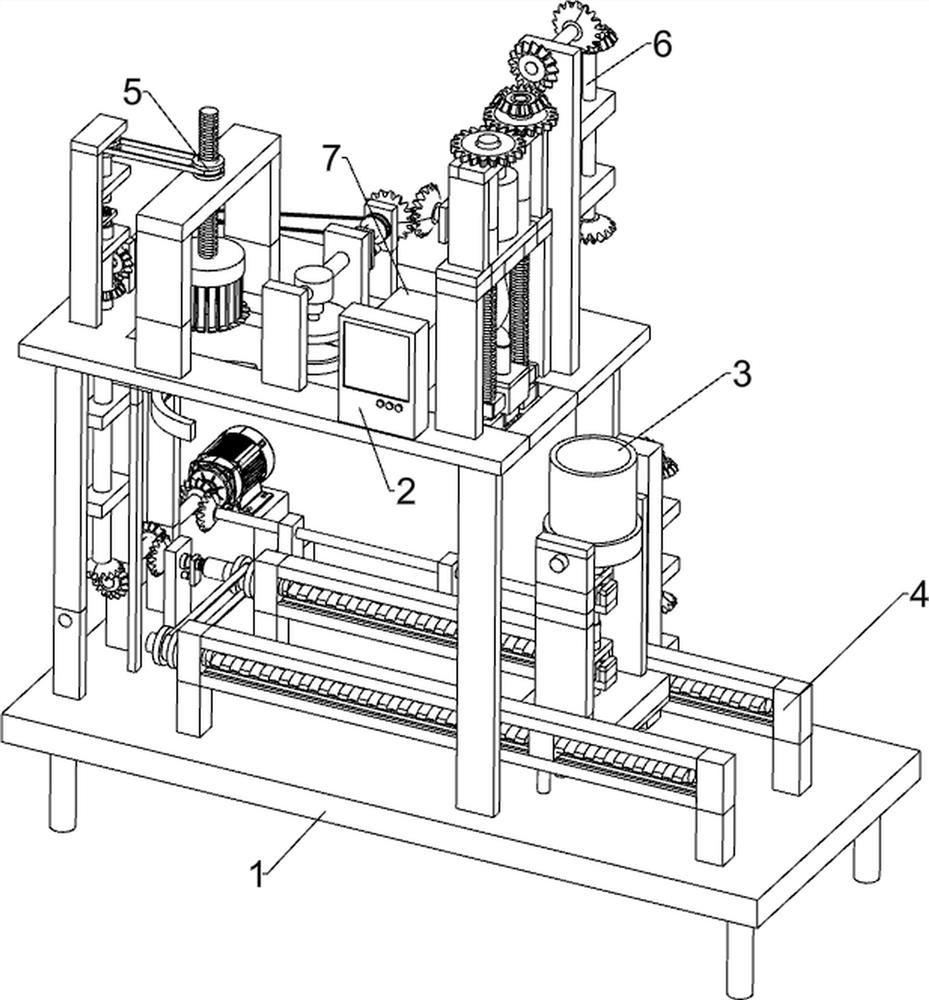

[0026] A motor painting device that can save raw materials, such as Figure 1-6 As shown, it includes a workbench 1, a control panel 2, an auxiliary component 3, a transport component 4, a paint scraping component 5, a painting component 6 and a dryer 7; the workbench 1 is connected to the control panel 2; the workbench 1 is connected to the The auxiliary component 3 is connected; the workbench 1 is connected with the transport component 4; the workbench 1 is connected with the paint scraping component 5; the workbench 1 is connected with the painting component 6; the workbench 1 is connected with the dryer 7; The component 3 is connected with the transport component 4; the transport component 4 is connected with the paint scraping component 5; the paint scraping component 5 is connected with the painting component 6.

[0027] Working principle: when the device is used, the motor that needs to be painted is placed on the auxiliary component 3 manually, and then the control pan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap