Mixed solution supply device for rolling equipment

A technology of mixing solution and rolling equipment, applied in the direction of metal rolling, metal rolling, workpiece lubrication device, etc., can solve the problems of interruption and slippage of the whole line, reduce friction, prevent slippage and meandering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

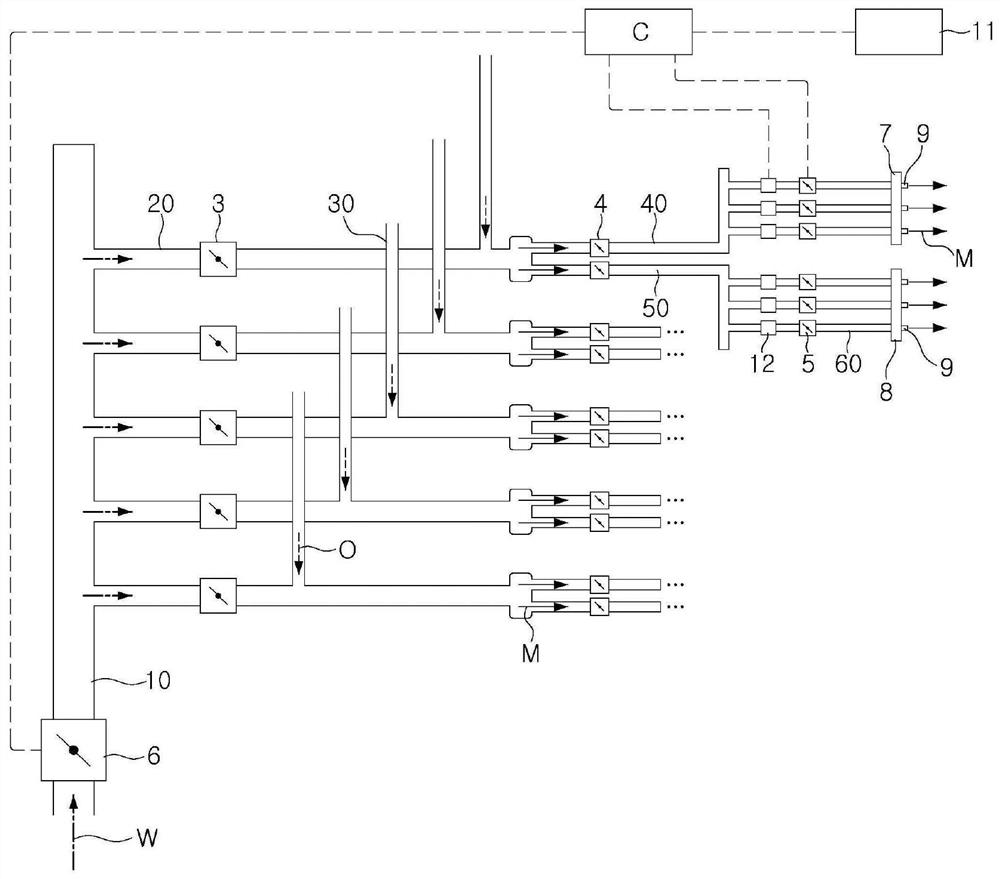

Method used

Image

Examples

Embodiment Construction

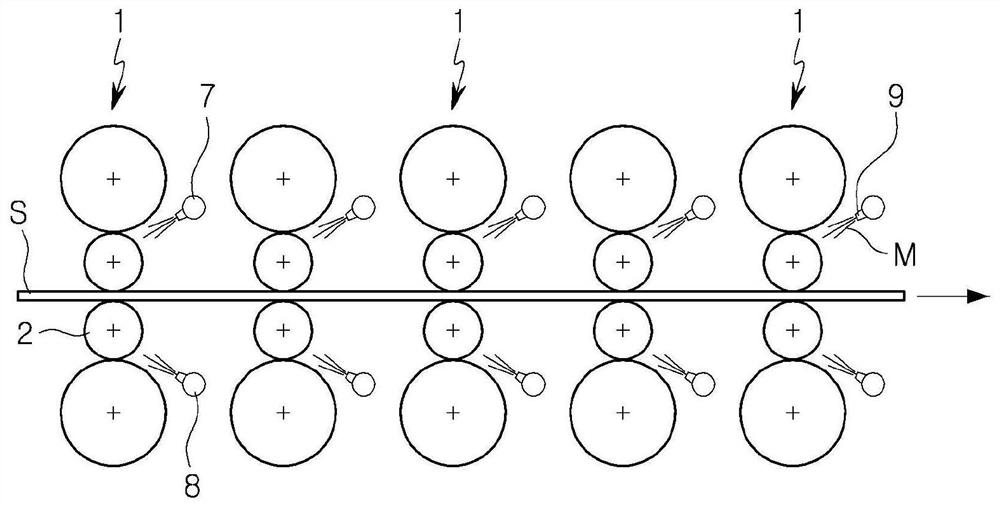

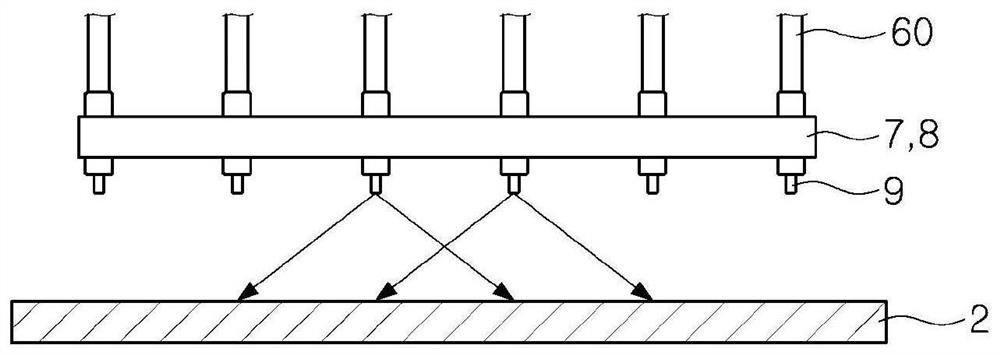

[0018] In the following, the present invention will be described in detail by means of exemplary figures. When assigning reference signs to components in each figure, even if the same components are shown in different figures, the same reference signs are used. In addition, when describing the present invention, when it is judged that the detailed description of related known structures or functions may obscure the gist of the present invention, the detailed description will be omitted.

[0019] For example, in the hot rolling process in the iron and steel manufacturing process, a mixed solution of cooling water and rolling oil is supplied to each stand so that it can be sprayed to the rolls through the nozzle. In the lubricated rolling, rolling oil and flowing cooling water are appropriately mixed and used according to process conditions.

[0020] However, if the flow rates of the cooling water flowing through the plurality of brackets are different, the ranges covered by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com