Automatic high-efficiency production device for chain plates in chains

A production device and inner chain plate technology, applied in the direction of feeding device, storage device, positioning device, etc., can solve the problems of high cost and complicated processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

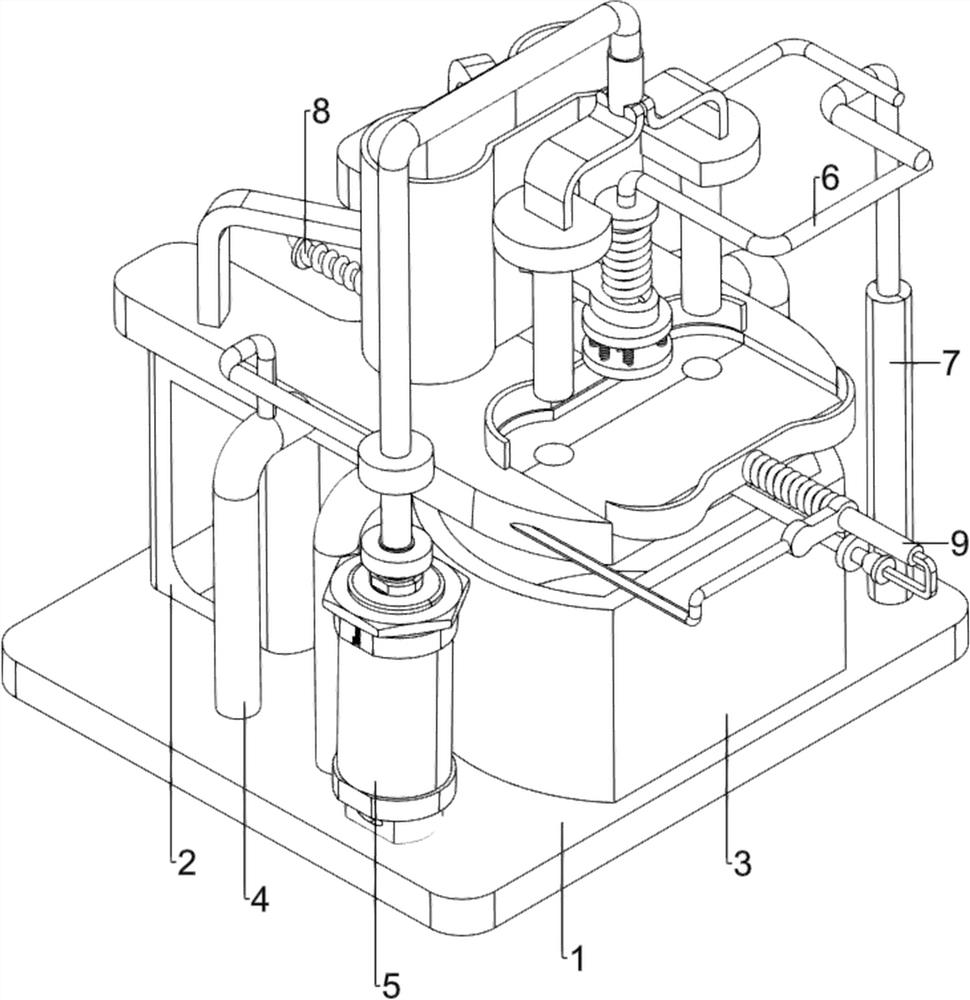

[0058] An automatic high-efficiency production device for chain inner chain plates, such as figure 1 As shown, it includes a floor 1, a first support back seat 2, an iron sheet collection frame 3, a support mechanism 4 and a stamping mechanism 5, the first support back seat 2 is arranged in the middle of the upper rear side of the floor 1, and the upper front side of the floor 1 The middle part is provided with sheet iron collecting frame 3, and the center on the floor 1 is provided with support mechanism 4, and support mechanism 4 is connected with the first support back seat 2, and the front left side on the floor 1 is provided with sheet punching mechanism 5.

[0059] When the chain plate needs to be punched and punched to produce chains, this automatic and efficient production device for chain plates inside the chain can be used. First, the chain plate punching mechanism 5 is placed on the support mechanism 4, and then the punching mechanism 5 is opened to punch the plates....

Embodiment 2

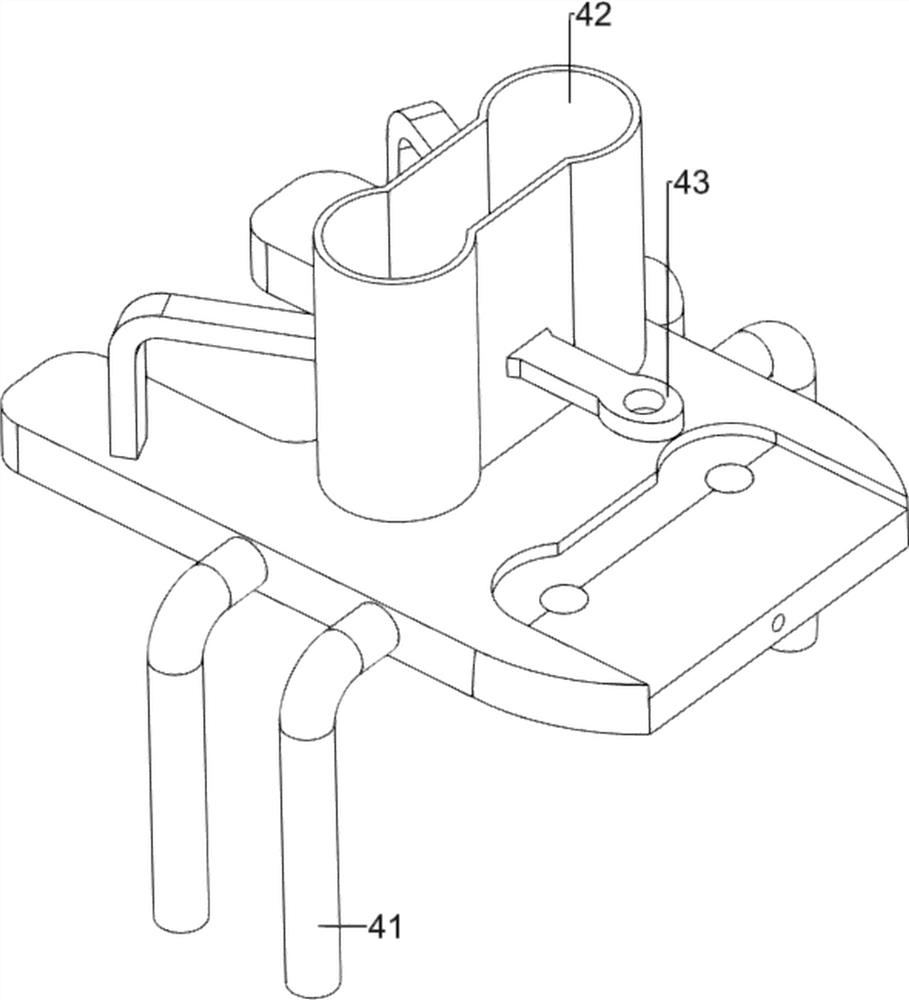

[0061] On the basis of Example 1, such as figure 2 with image 3 As shown, the support mechanism 4 includes a first support table frame 41, a discharge frame 42 and a first support rod block 43, the floor 1 is provided with a first support table frame 41 in the middle, and the rear side of the first support table frame 41 top is provided There is a discharge frame 42, and the lower part of the front side of the discharge frame 42 is provided with a first support bar block 43.

[0062] People stack a plurality of chain plates into the discharge frame 42, and the bottom chain plate falls on the first supporting table frame 41. When stamping is required, the bottom chain plate is intermittently pushed forward to the bottom of the punching mechanism 5, Realize the effect of chain plate feeding.

[0063]The punching mechanism 5 includes a cylinder 51, a push rod 52, a first stabilizing frame 53, a first connecting block 54, a knife punching device 55 and a first branch 56, and a...

Embodiment 3

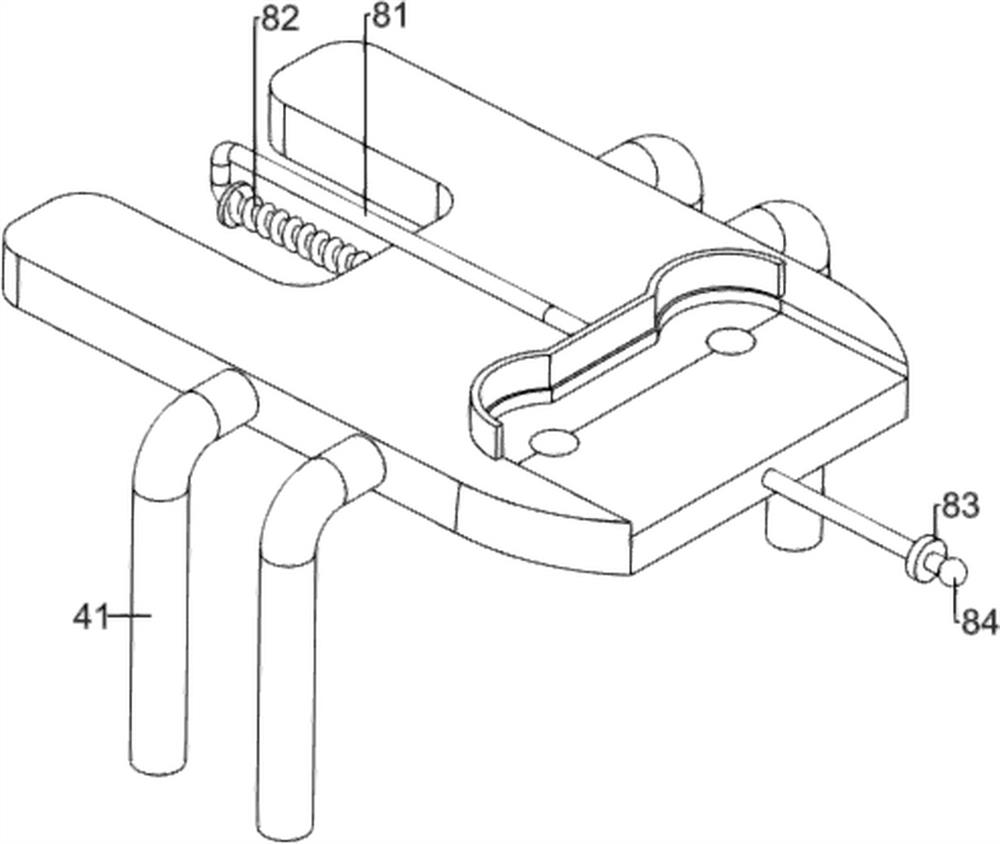

[0066] On the basis of Example 2, such as Figure 4-7 As shown, it also includes a front pressing mechanism 6, and the front pressing mechanism 6 includes a pressure device 61, a first spring 62, a pressure-assisting spring device 63 and a round iron block 64, and the front side sliding type of the first support rod block 43 is designed There is a pressure device 61, the first spring 62 is wound around the lower part of the pressure device 61, the top of the first spring 62 is connected to the pressure device 61, the bottom end of the first spring 62 is connected to the first support bar block 43, and the bottom of the pressure device 61 is provided with a pressure assisting Spring device 63, the bottom end of pressure-assisting spring device 63 is provided with round iron piece 64.

[0067] People press down the pressure device 61, so that the pressure device 61 slides downward along the first support bar block 43, the first spring 62 is compressed, and the pressure device 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com