Cut-off prevention automobile wire harness and using method thereof

A technology for automobile wiring harnesses and cables, applied in chemical instruments and methods, vehicle components, circuits or fluid pipelines, etc., can solve the problems of automobile circuit interruption, poor strength of automobile wires, and cutting of sharp weapons, etc., to prevent circuit interruption, The effect of preventing breakage and increasing the protective ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

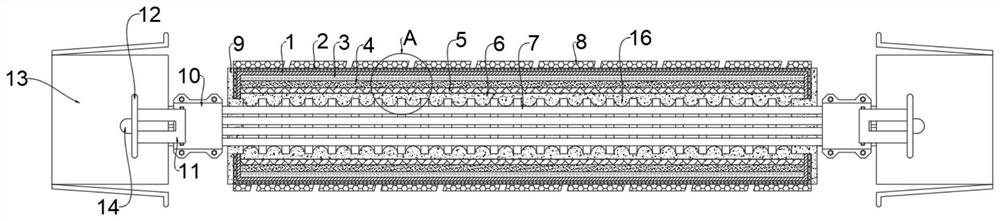

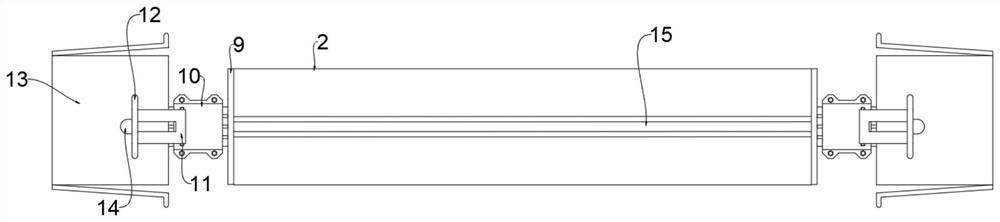

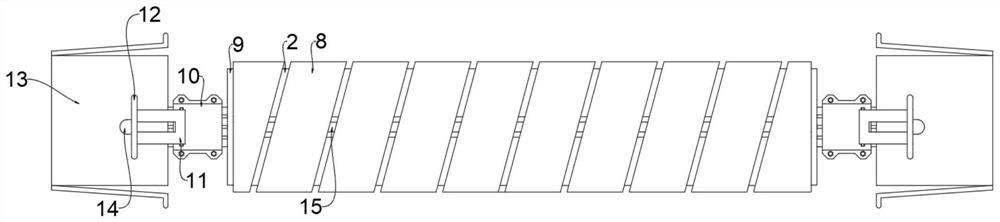

[0029] see Figure 1-5 , an embodiment provided by the present invention: an anti-cutting automobile wire harness, including a polyethylene protective layer 1, and an anti-cutting wire mesh 2 is installed on the outside of the polyethylene protective layer 1, and the installation of the anti-cutting wire mesh 2 can increase the device When a sharp object is in contact with it, the metal wire inside the anti-cut wire mesh 2 can prevent the sharp object from cutting the device, prevent the interruption of the car circuit, and avoid irreparable losses. The anti-cut wire mesh 2 and poly The vinyl protective layer 1 is fixedly connected, and a soft rubber layer 3 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com