Method for improving low-temperature impact toughness of 380MPa-grade hot-rolled wheel steel

A technology of low temperature impact toughness and impact toughness, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

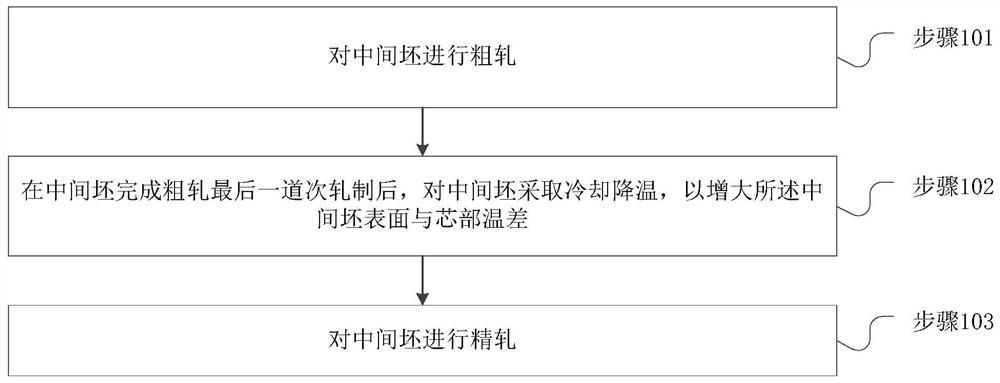

Method used

Image

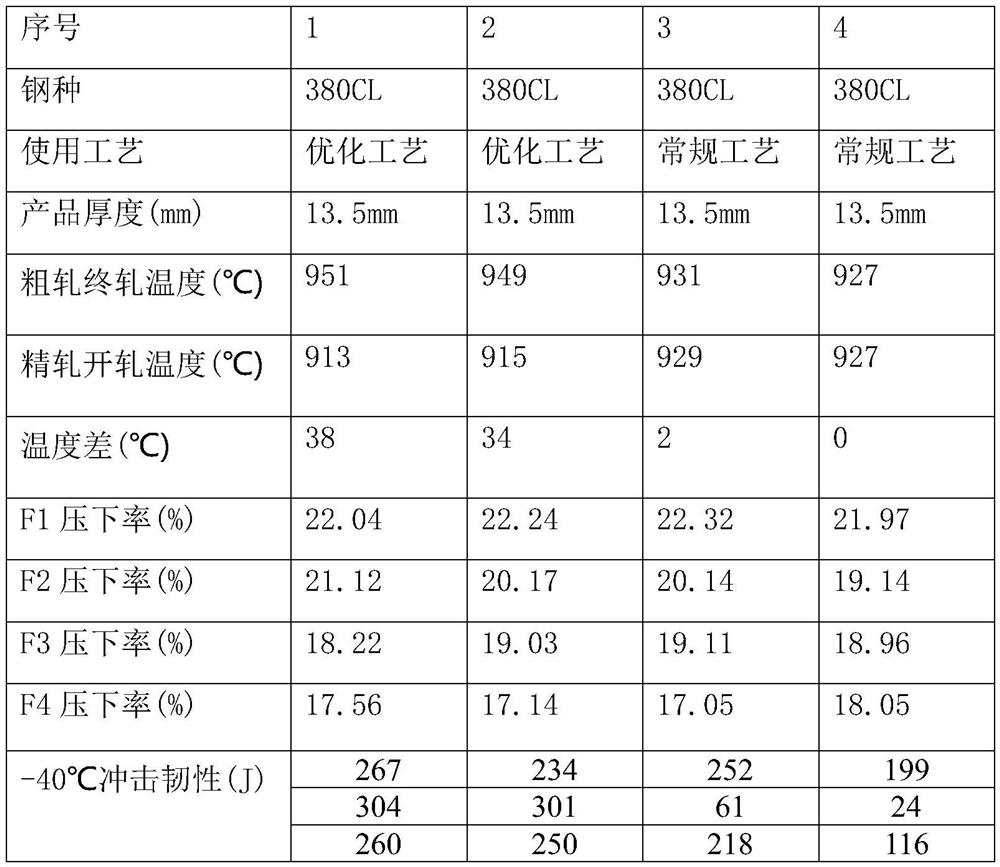

Examples

Embodiment Construction

[0030] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0031] In the rolling process of hot-rolled wheel steel, due to the limitation of rolling deformation characteristics and deformation amount, the closer the material is to the center of the intermediate billet in the thickness direction, the smaller the deformation amount is, and the smaller the deformation amount is, the greater the grain fragmentation degree of the material is. The lower the grain size, the larger the grain size, which causes the grain size of the material in the thickness direction of the hot-rolled wheel steel to be produced to be inconsistent, that is, the grain size of the core material in the thickness direction of the wheel steel is too large. The larger the grain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com