Push rod structure of upper thread clamping device and upper thread clamping device of embroidery machine

A clamping device and clamping structure technology, applied in the field of embroidery machines, can solve the problems of limited side space, the inability of the electromagnet to drive the ejector rod, affecting the normal installation of the upper thread clamping device, etc., so as to avoid interference and avoid the influence of installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

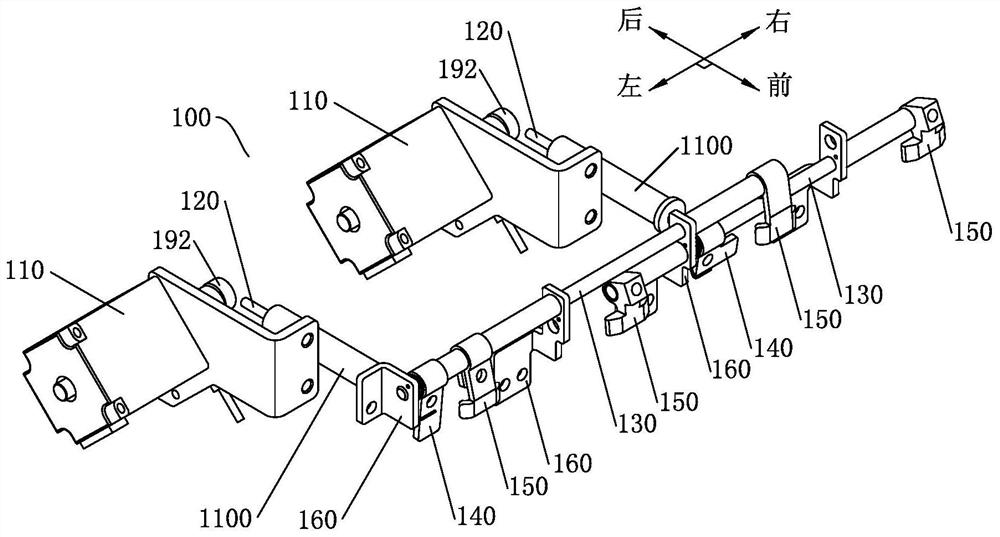

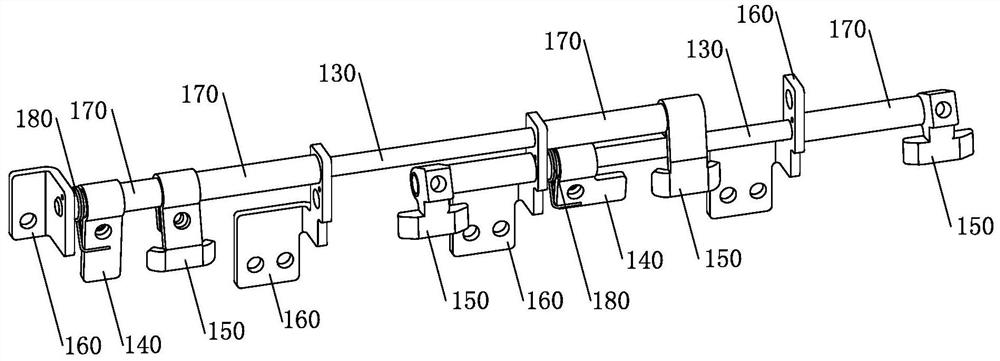

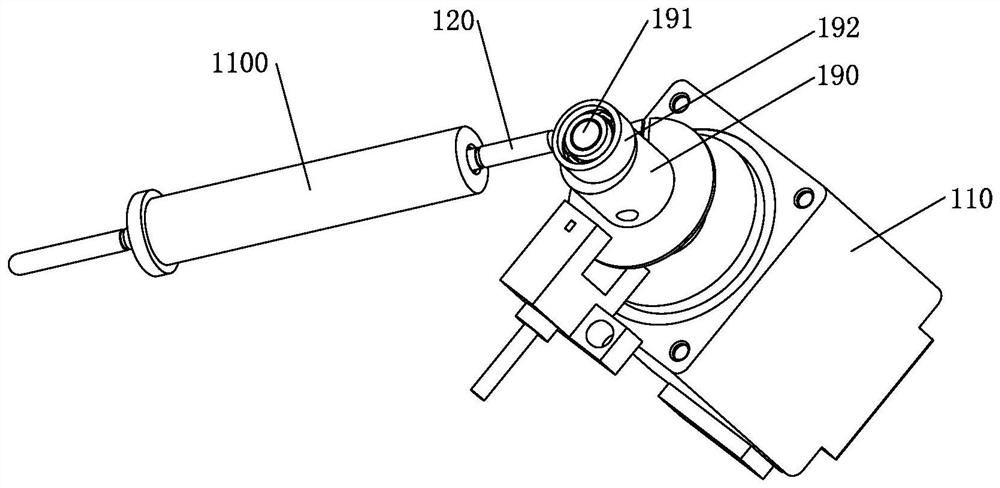

[0035] Such as Figure 1 to Figure 4 As shown, Embodiment 1 of the present invention provides a push rod structure of a needle thread clamping device. The push rod structure 100 comprises a motor 110, a push rod 120, a rotating shaft 130, a push piece 140 and a blocking piece 150. The front end of rod 120 conflicts with push piece 140, and motor 110 can drive push rod 120 to move forward.

[0036] The left-right direction shown in the figure is the horizontal direction, and the front-rear direction and the left-right direction are set vertically on the horizontal plane. The axial direction of the rotating shaft 130 is arranged along the left-right direction, and the axial direction of the push rod 120 is arranged along the front-rear direction, that is, the push rod 120 is arranged vertically to the rotating shaft 130 .

[0037] In order to install the rotating shaft 130, the push rod structure also includes a fixed seat 160, the fixed seat 160 is provided with a through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com