A structure and construction method for detecting surface curvature of supporting crown beams

A surface bending and crown beam technology is applied in the structure and construction field to detect the surface curvature of support crown beams, which can solve the problems of waste of resources, low mechanical automation, and heavy user workload, and achieve fast and stable support and automatic construction. High, time-saving and labor-saving pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

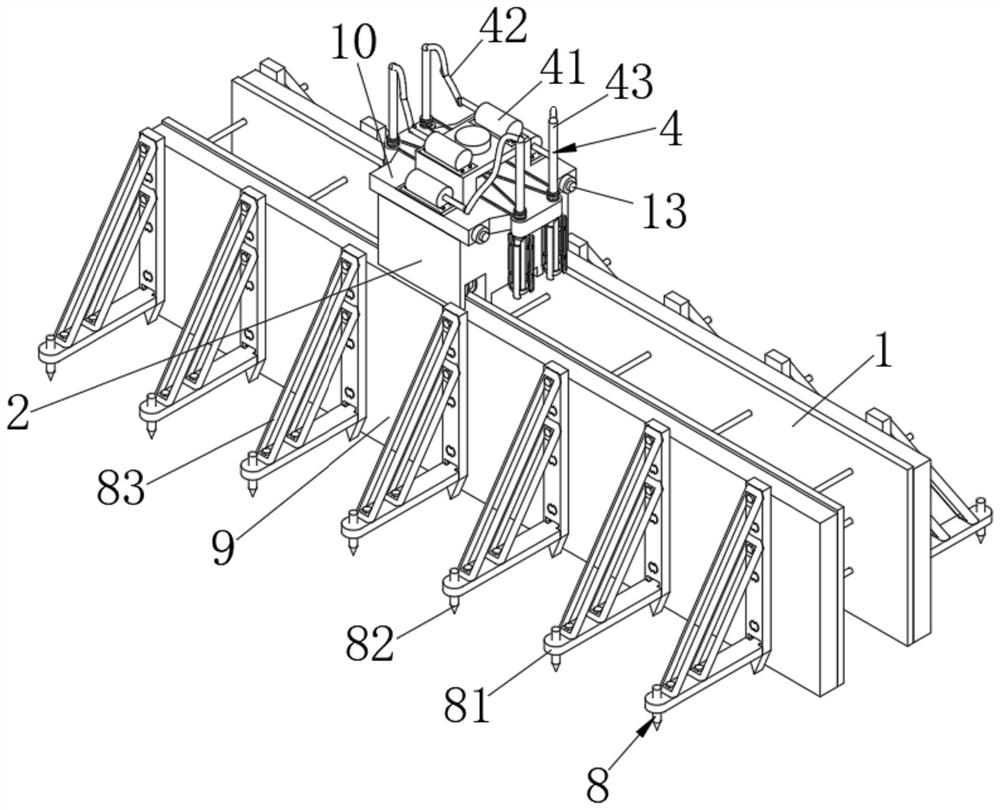

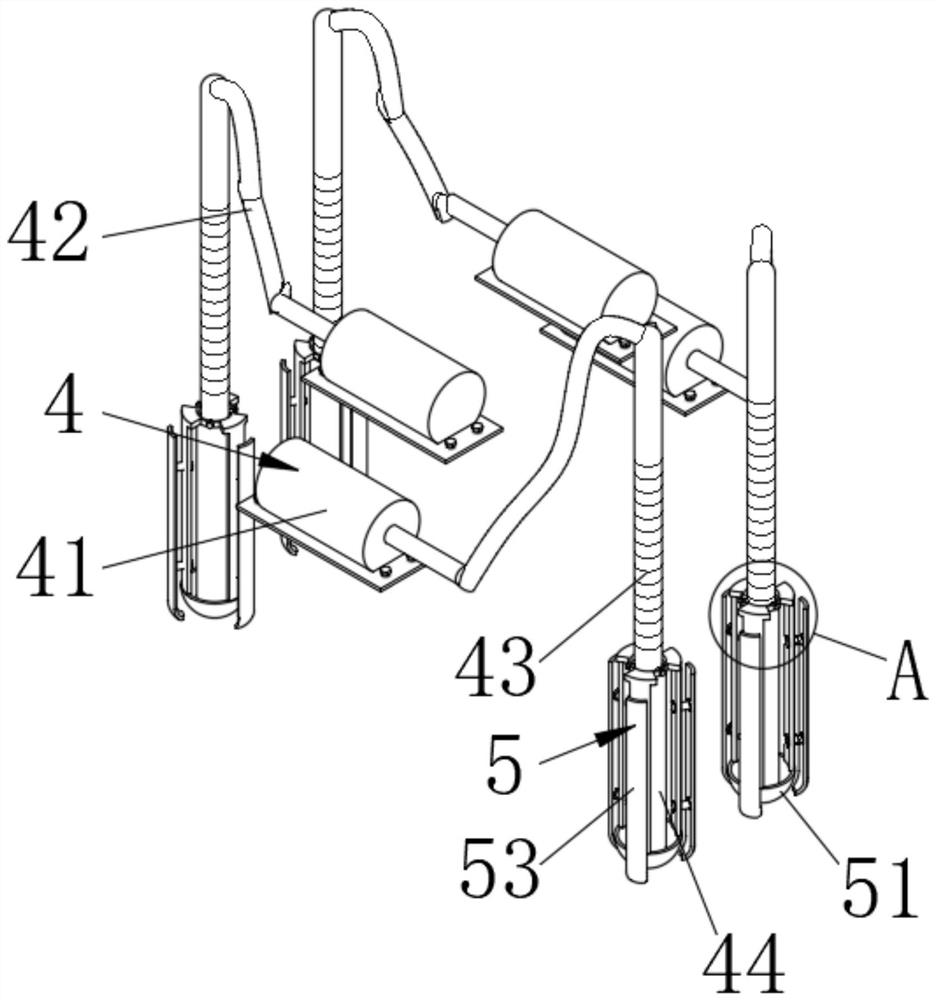

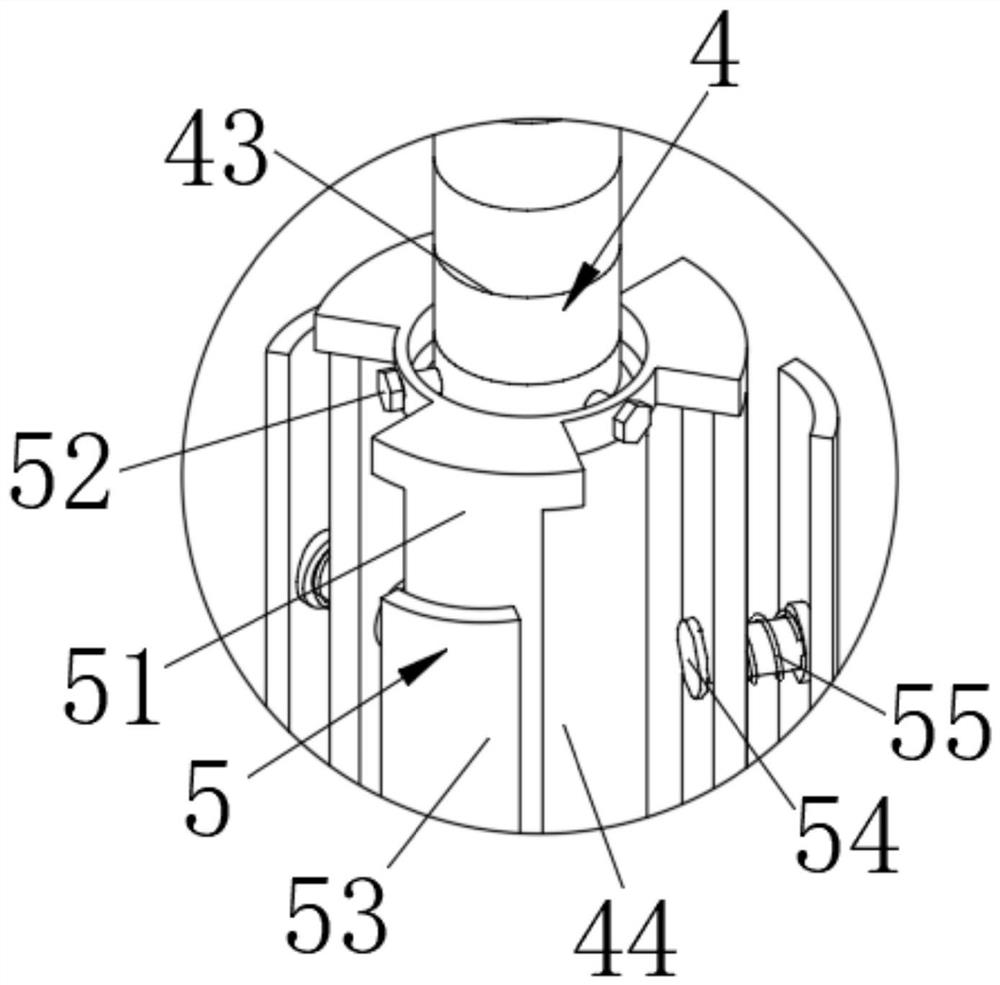

[0046] combine Figure 1-9 , the embodiment of the present invention discloses a structure for detecting the curvature of the surface of the support crown beam, including a template body 1, the number of the template body 1 is two, the top of the template body 1 is provided with a frame 2, and the The bottom is provided with a drive mechanism 1 3, the drive mechanism 1 3 includes a motor 1 31 installed at the bottom of the frame 2, the output shaft of the motor 1 31 is fixedly connected with a drive bevel gear 32, and both sides of the bottom of the frame 2 are provided with rectangular cavities The body 33, the front side and the rear side of the inner cavity of the rectangular cavity 33 are provided with runners 34, a transmission rod 36 is fixedly connected between the two runners 34 on the front side, and the surface of the transmission rod 36 is fixedly connected with a stress cone The gear 35, the force bevel gear 35 and the drive bevel gear 32 mesh with each other, and ...

Embodiment 2

[0051] combine Figure 1-9 , the embodiment of the present invention discloses a structure for detecting the curvature of the surface of the support crown beam, including a template body 1, the number of the template body 1 is two, the top of the template body 1 is provided with a frame 2, and the The bottom is provided with a drive mechanism 1 3, the drive mechanism 1 3 includes a motor 1 31 installed at the bottom of the frame 2, the output shaft of the motor 1 31 is fixedly connected with a drive bevel gear 32, and both sides of the bottom of the frame 2 are provided with rectangular cavities The body 33, the front side and the rear side of the inner cavity of the rectangular cavity 33 are provided with runners 34, a transmission rod 36 is fixedly connected between the two runners 34 on the front side, and the surface of the transmission rod 36 is fixedly connected with a stress cone The gear 35, the force bevel gear 35 and the drive bevel gear 32 mesh with each other, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com