Slotter apparatus, and machine for manufacture of carton

A technology of control device and notch groove, which is applied in the direction of container manufacturing machinery, packaging, transportation and packaging, etc., can solve the problems of notch groove cracking and crushing, and achieve the effect of suppressing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

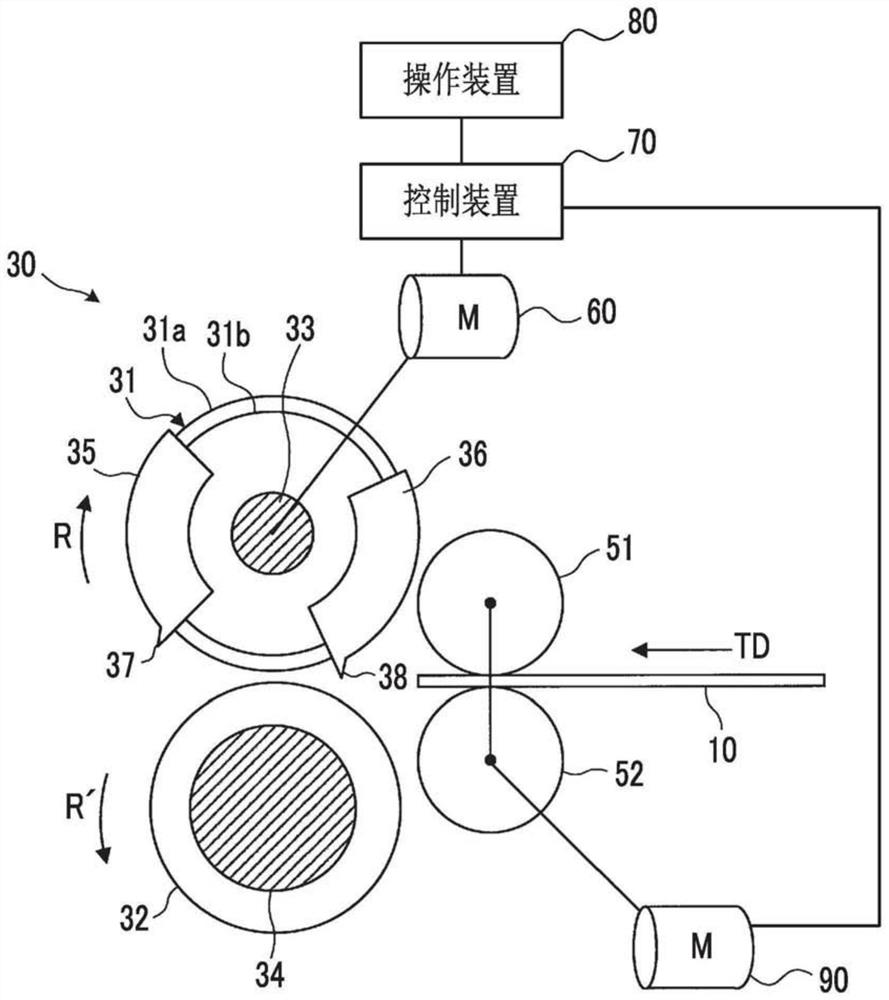

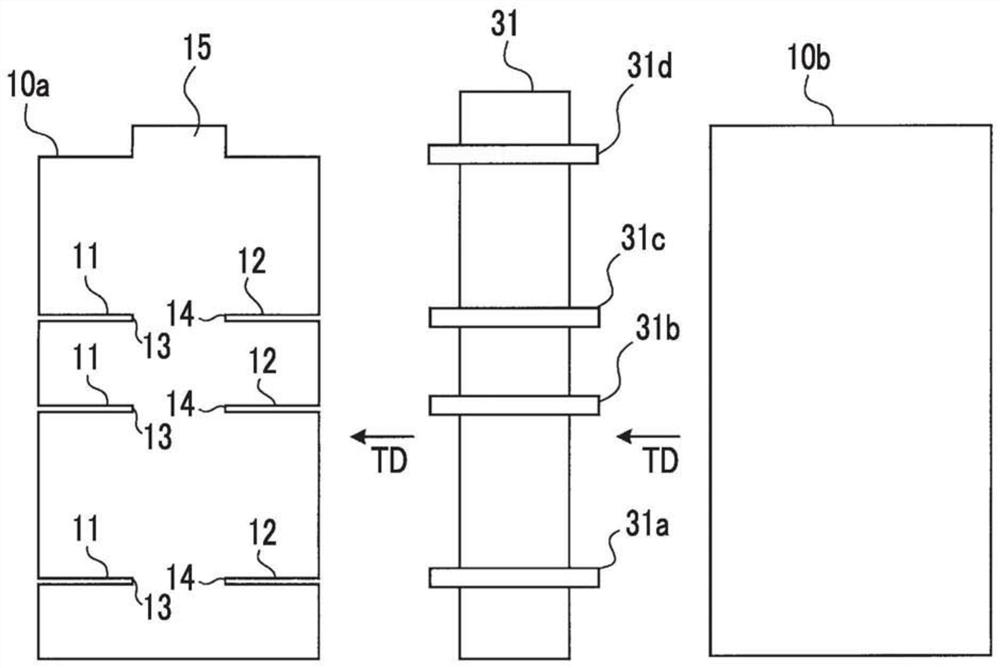

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0031] In addition, each embodiment shown below is just an illustration, and it is not intended to exclude the application of various deformation|transformation and techniques which are not clearly shown in the following embodiment. The configurations of the following embodiments can be implemented with various modifications without departing from the gist thereof, and can be selected or combined as necessary.

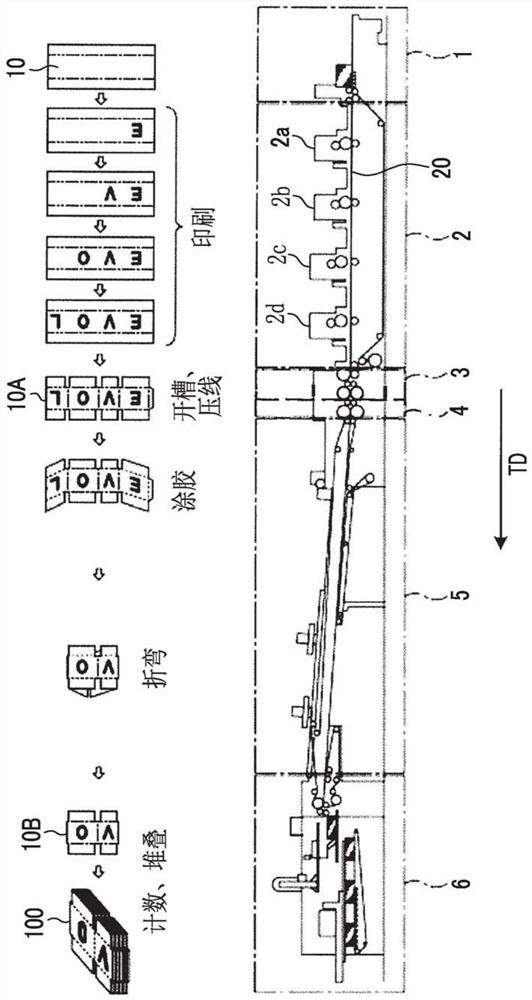

[0032] 〔The overall structure of the box making machine〕

[0033] The slotting device according to this embodiment is a slotting device provided in a box making machine. First, refer to figure 2 A box making machine including the slotting device according to this embodiment will be described. In addition, in the following description, the conveyance direction TD of a cardboard is set to the front, the opposite direction is set to the back, the direction of g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com