Automatic detecting, positioning and accurate fire extinguishing robot system and using method

A fire-fighting robot and autonomous detection technology, which is applied to TV system components, fire rescue, TV, etc., can solve problems such as complex types, difficult fire detection, and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

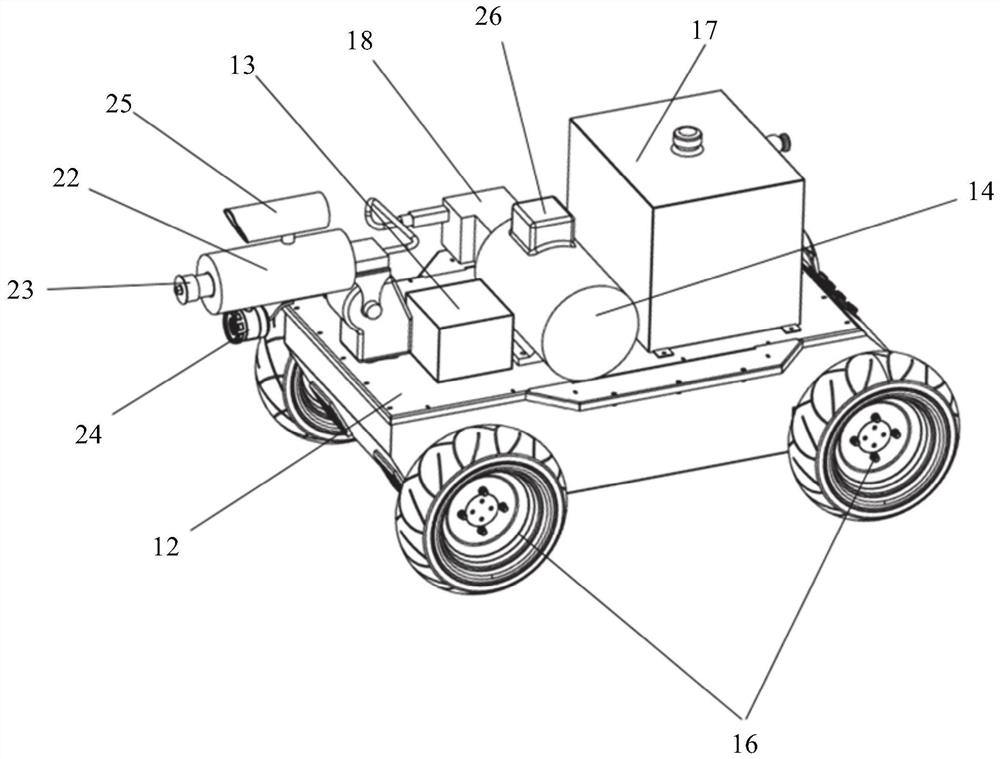

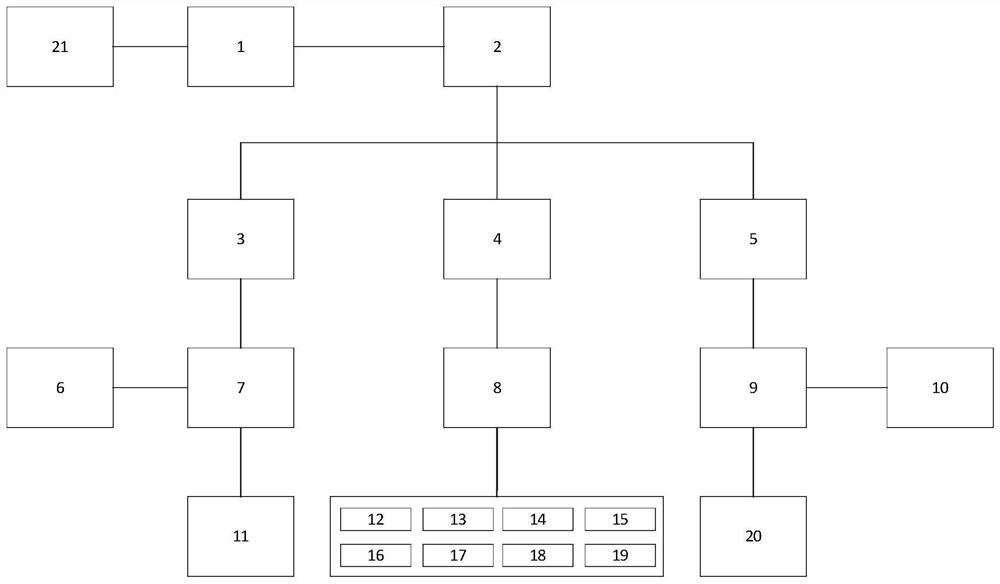

[0047] In a typical embodiment of the present invention, refer to figure 1 and figure 2 As shown, an autonomous detection and positioning and precise fire extinguishing robot system includes: a robot body 8, the robot body 8 includes a chassis 12, a fire detection and extinguishing device 19 and a flame detector 24, the chassis 12 is provided with a walking mechanism 16, and the fire detection and extinguishing device can be rotatably installed On the chassis, the flame detector is installed on the detection and fire extinguishing device; the fire positioning subsystem is installed on the workplace of the robot body, and is used to judge whether the fire occurs and locate the fire position; the automatic navigation subsystem 9 is used to guide the robot body to The location of the fire is moved; the system host is separately connected to the fire positioning subsystem, the automatic navigation subsystem and the controller of the robot body.

[0048] Specifically, the chassis...

Embodiment 2

[0080] The difference between this embodiment and embodiment one is:

[0081] The detection fire extinguishing device includes a foam fire extinguisher, and the switch of the foam fire extinguisher is connected with the controller of the robot body.

Embodiment 3

[0083] The difference between this embodiment and embodiment one is:

[0084] The binocular vision camera can also be replaced by other types of cameras.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com