A Simple Preparation Method of Continuous Dense Mordenite Membrane

A mordenite and dense technology, which is applied in the field of inorganic membrane pervaporation separation, can solve the problems of poor binding force between the carrier and the seed crystal, and the inability to prepare zeolite membranes, so as to improve the binding force, good separation performance and repeatability, and improve dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Use 600 and 1200 mesh sandpaper to clean the carrier tube (macroporous α-Al 2 o 3 carrier tube) to reduce the surface roughness. After grinding, boil in deionized water for 15 minutes, take it out and let it cool naturally, then put it in an ultrasonic cleaner for 5 minutes to remove residues in the film. After washing with deionized water, both ends are sealed in the Preheat in a blast oven at 175°C for 2 hours.

[0022] (2) Ultrasonic dispersion of mordenite molecular sieve (purchased by Zhonghe Petrochemical, conventional) in 0.5wt.% silica-zirconia sol (Si / Zr=1 in the sol), the concentration of the seed liquid is 3wt.%, Coat the crystal on the carrier tube in step (1) by dipping and pulling method, the soaking time is 25s, take it out and put it into a blast oven to dry at 80°C for 3h.

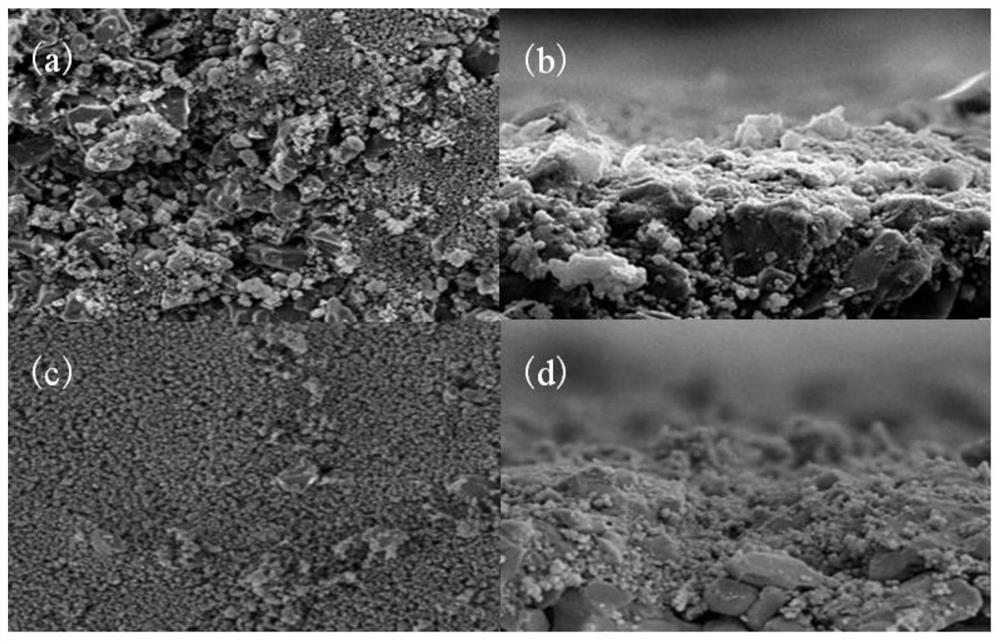

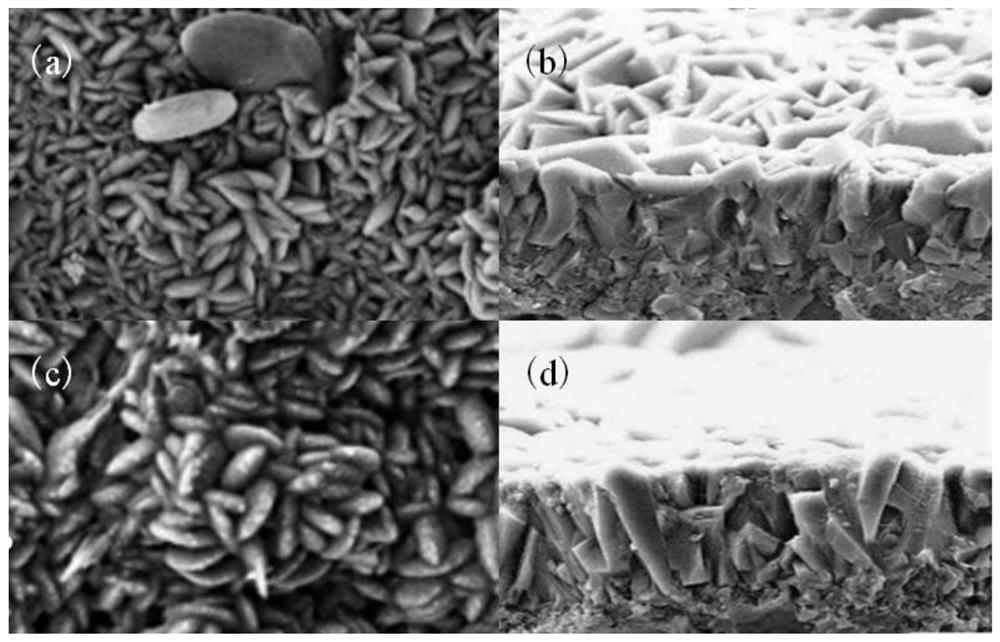

[0023] (3) Wipe off excess loose seed crystals on the carrier tube in step (2) with absorbent cotton, put it into a control furnace and bake at 550° C. for 6 hours to form a s...

Embodiment 2

[0028] The 0.5 wt.% silica-zirconia sol in step (2) of Example 1 was replaced with 1 wt.% silica-zirconia sol, and the rest of the operations were the same as in Example 1. The pervaporation performance of the prepared mordenite membrane is shown in Table 2.

Embodiment 3

[0030] The 0.5wt.% silica-zirconia sol in step (2) of Example 1 was replaced with 2wt.% silica-zirconia sol, and the rest of the operations were the same as in Example 1. The pervaporation performance of the prepared mordenite membrane is shown in Table 2.

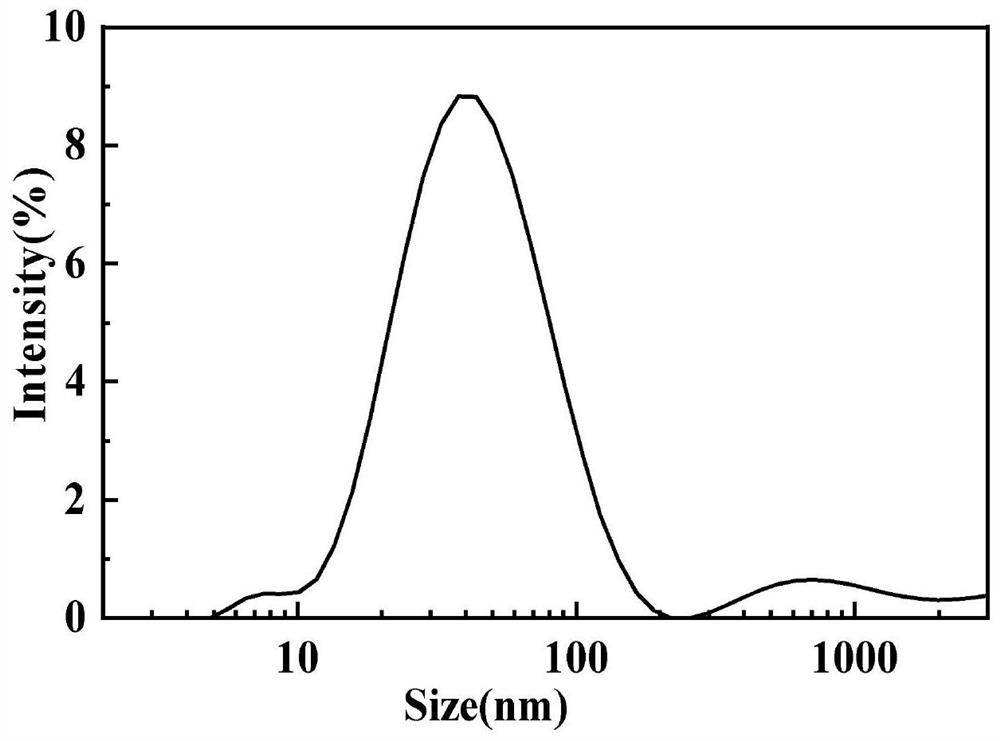

[0031] image 3 It is the particle size distribution figure of silica-zirconia sol in embodiment 1 and embodiment 2-3, as can be seen from the figure that SiO 2 -ZrO 2 The particle size of the sol is about 40nm.

[0032] Figure 4 It is silica-zirconia (a), seed crystal (b) and SiO in embodiment 1 2 -ZrO 2 / The FT-IR spectrogram of seed crystal (c), as can be seen from the figure 3448cm -1 、1636cm -1 and 1400cm -1 The absorption peak at is caused by the stretching vibration, deformation vibration and out-of-plane bending vibration of OH group. Add SiO to the seed 2 -ZrO 2 After sol, 3448cm -1 and 1400cm -1 The peak intensity at , which means that SiO 2 -ZrO 2 The sol increases the OH groups in the seed liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com