Integrated steel-rubber composite lining plate

A composite liner and one-piece technology, applied in the direction of grain processing, etc., can solve the problems such as the lifting bar is easy to fall off, and achieve the effect of saving time and effort for installation and disassembly, long service life, and improving service performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

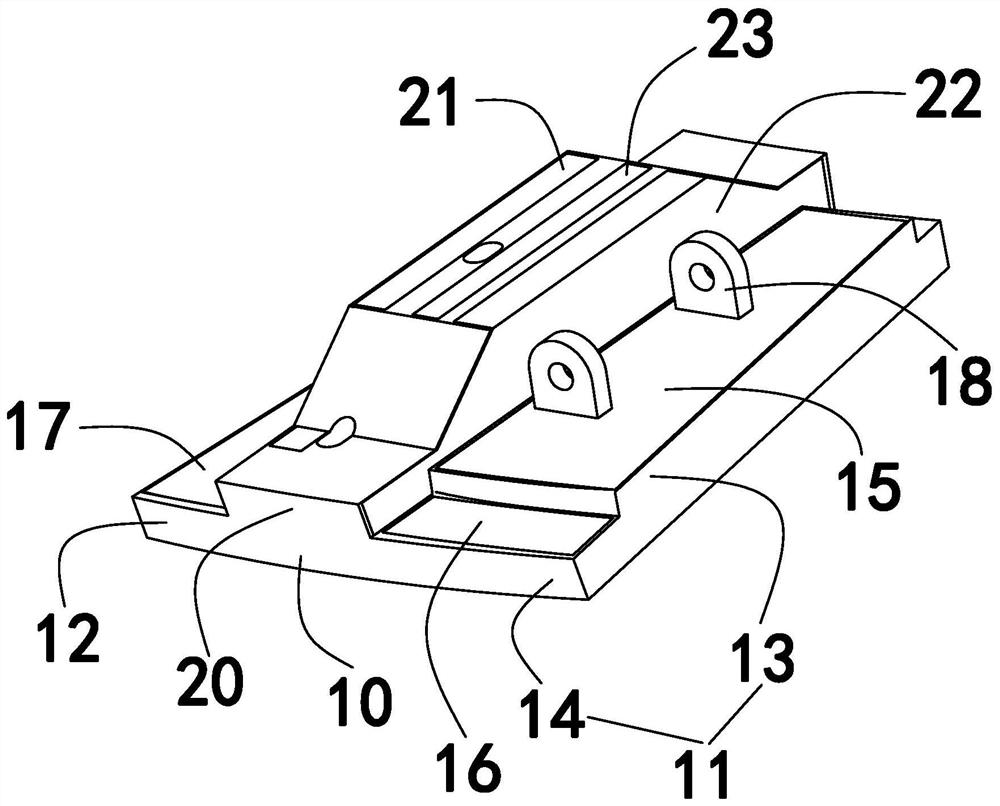

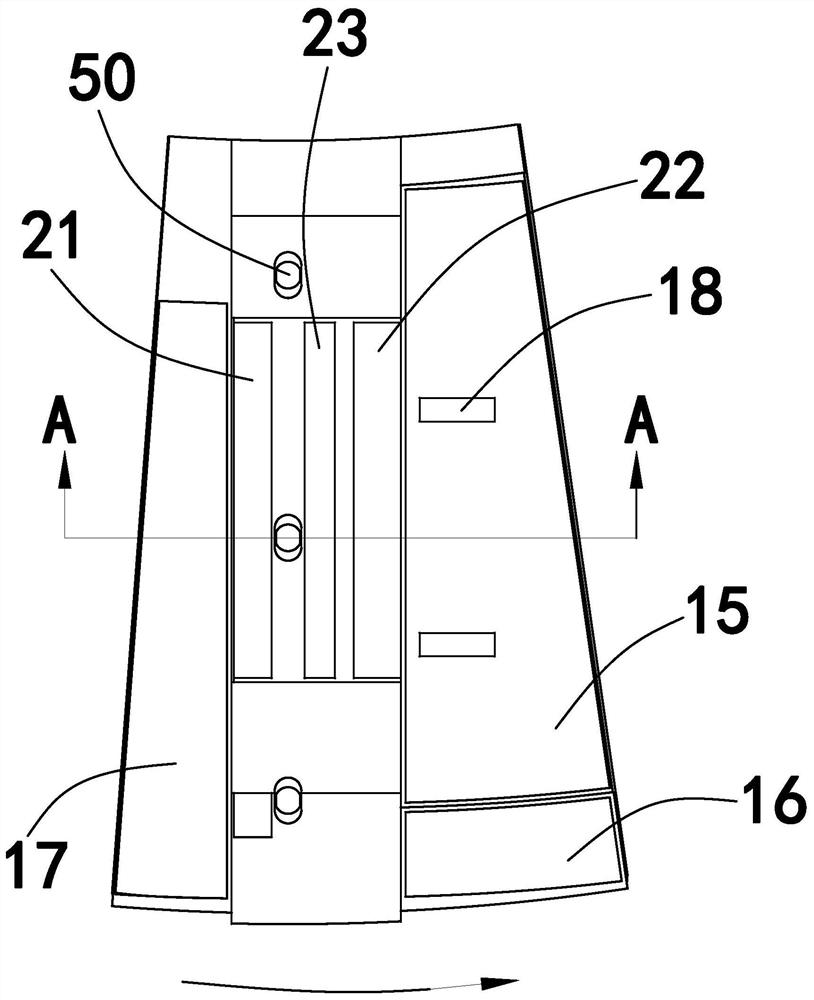

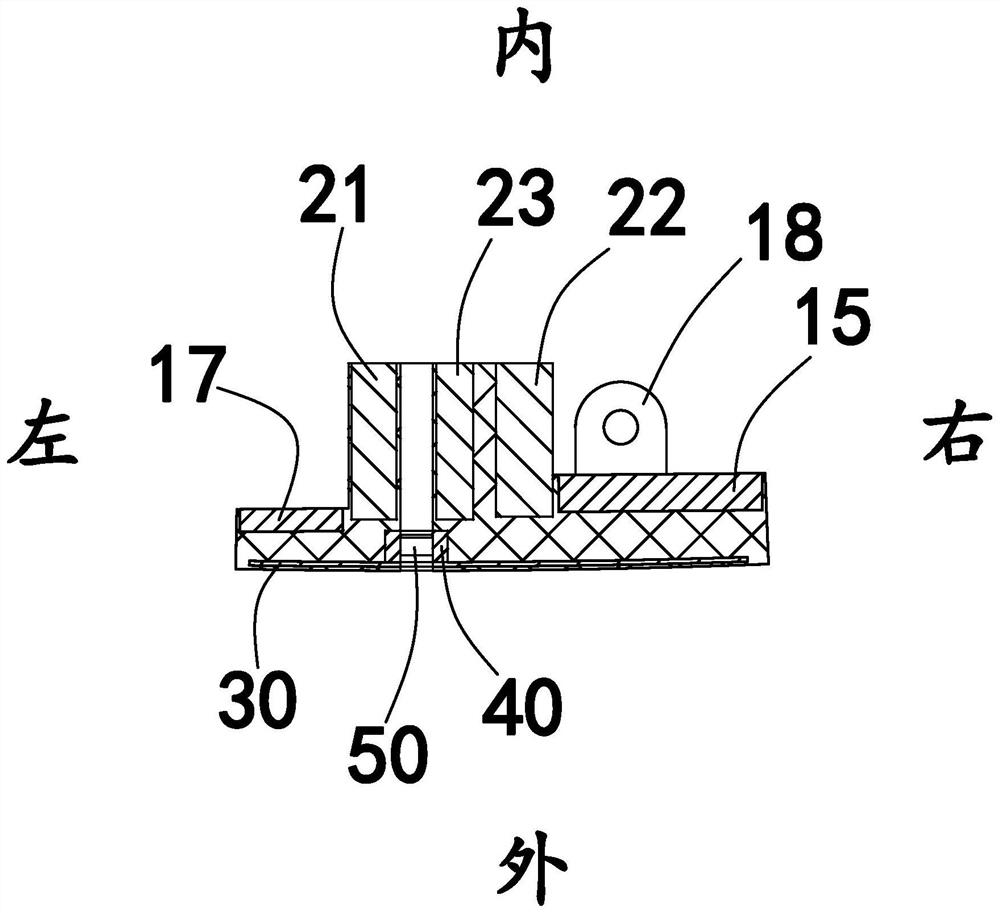

[0034] Such as Figure 1~3 As shown, the present invention provides an integrated steel-rubber composite liner, the liner includes: a rubber body; the rubber body includes an integrally formed backing part 10 and a lifting part 20, and the lifting part 20 is located on the pad The inner side of the plate portion 10; the lifting portion 20 is embedded with a first steel plate 21, a second steel plate 22 and a third steel plate 23; the first steel plate 21 and the second steel plate 22 are respectively located on the left and right sides of the lifting portion 20, It is used to resist the impact of steel balls and ore on the left and right sides of the lifting part; the third steel plate 23 is located between the first steel plate 21 and the second steel plate 22; and further strengthens the impact resistance of the lifting part 20.

[0035] The lifting part 20 embedded with the steel plate is integrally formed with the backing plate part 10, which not only retains the advantage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com