Anti-jamming anhydrous soil removing machine for lumps

A block, anti-seize technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of high desliming processing costs, coal pollution, dust pollution, etc. The effect of avoiding transportation cost and efficiency drop, improving separation efficiency and reducing separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

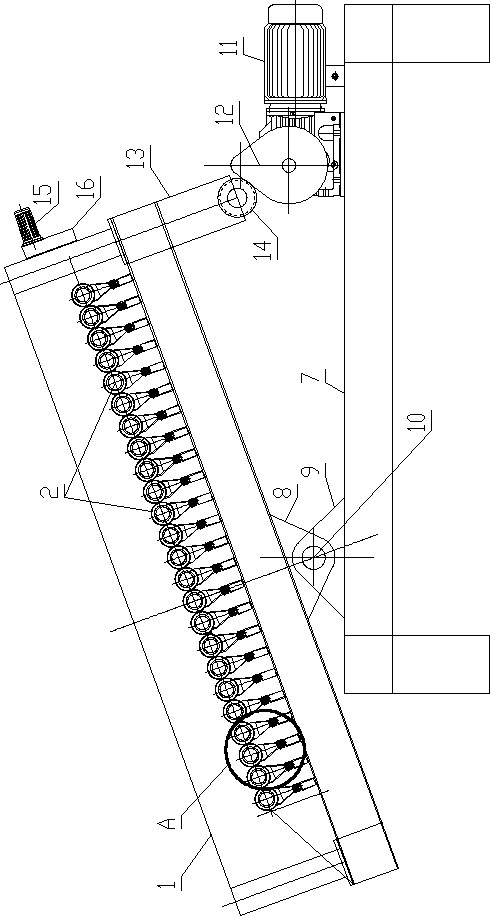

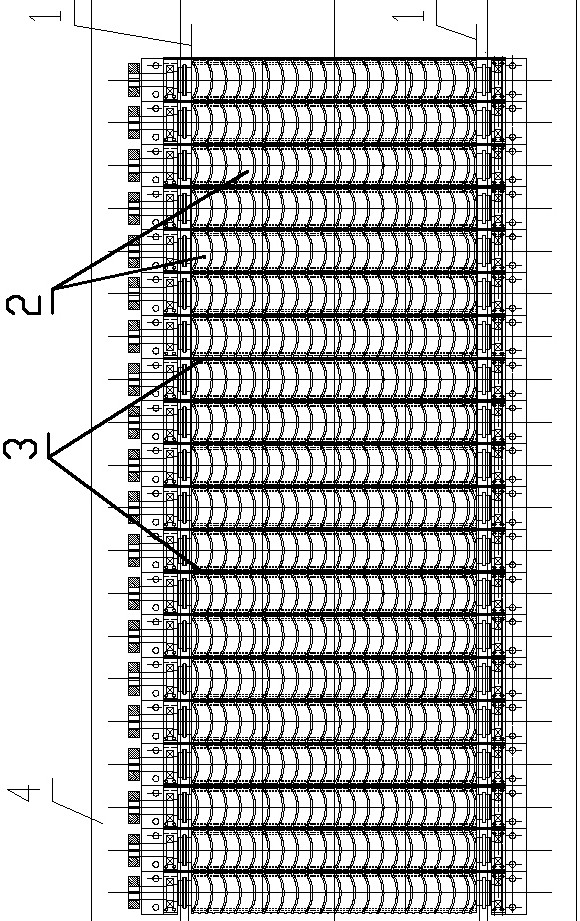

[0048] Such as Figure 1 to Figure 4 As shown, the water-free deslimer for anti-blocking blocks of the present invention includes a desliming tank 1 installed on the frame 4, and the moving direction of the material in the desliming tank 1 is forward, and the desliming tank 1 The upper part of the rear end is the feeding position and the bottom of the front end is the discharging position;

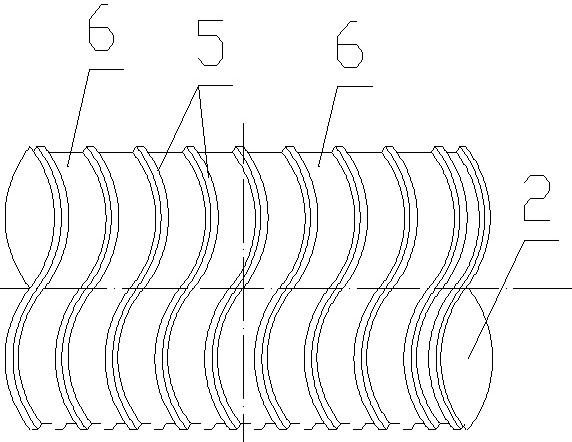

[0049] A row of mud scraping rollers 2 are evenly spaced in the desilting tank 1. The axes of each mud scraping roller 2 are located on the same plane and the plane is set with a low front and a rear high slope. The axial ends of each mud scraping roller 2 are installed on the On the frame 4, each mud scraping roller 2 forms a mud scraping roller group; the bearing is a conventional part, not shown in the figure.

[0050] A partition bar 3 is arranged between two adjacent mud scraping rollers 2, and the partition bar 3 extends along the length direction of the mud scraping roller 2 and is...

Embodiment 2

[0078] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the material driving mechanism includes a drive motor 11 installed on the base 7, an eccentric wheel 23 is installed on the output shaft of the drive motor 11, and the eccentric wheel 23 is hinged with a Rocking arm 24, the other end of rocking arm 24 is upwardly hinged with rear connection seat 25, and rear connection seat 25 is installed on frame 4 rear end bottoms.

[0079] When the eccentric wheel 23 rotates, the rocker arm 24 drives the frame 4 to swing up and down. In the process of swinging up and down, the material in the desilting tank 1 moves forward and downward due to the swing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com