Full-automatic riveting machine

A riveting machine, fully automatic technology, applied in the direction of cleaning methods, measuring devices, instruments, etc. using gas flow, can solve the problems of low production efficiency, easy fatigue in detection, cumbersome steps, etc., and achieve compact connection, stable quality, and smooth operation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

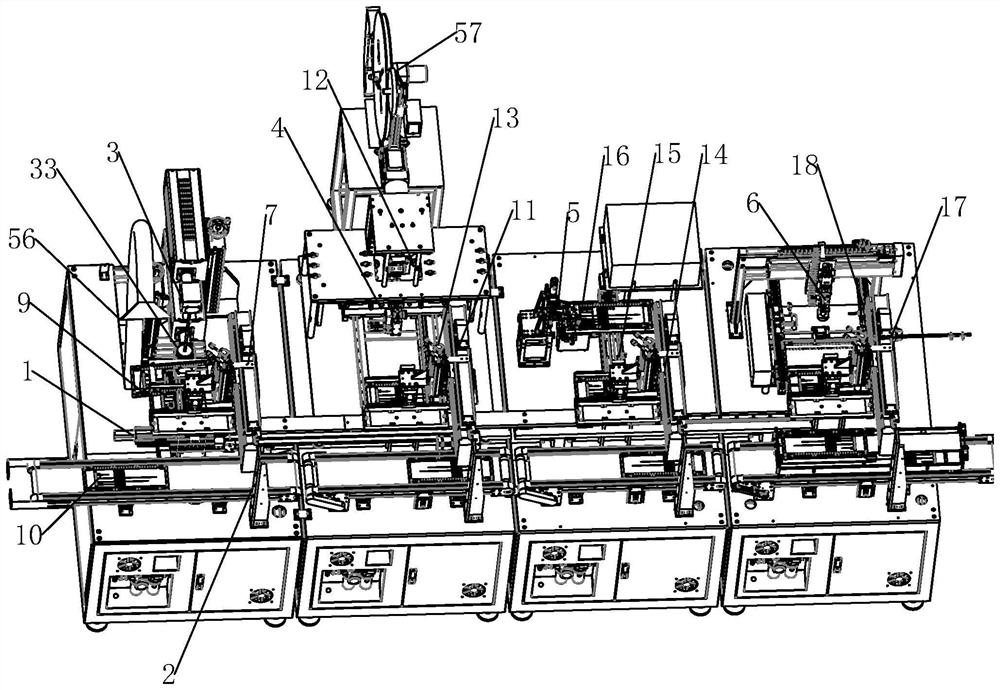

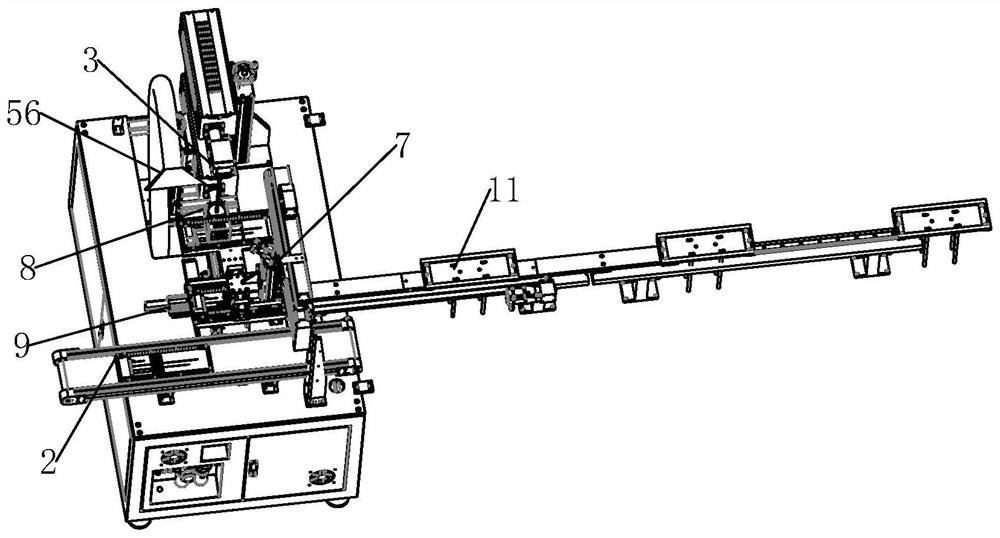

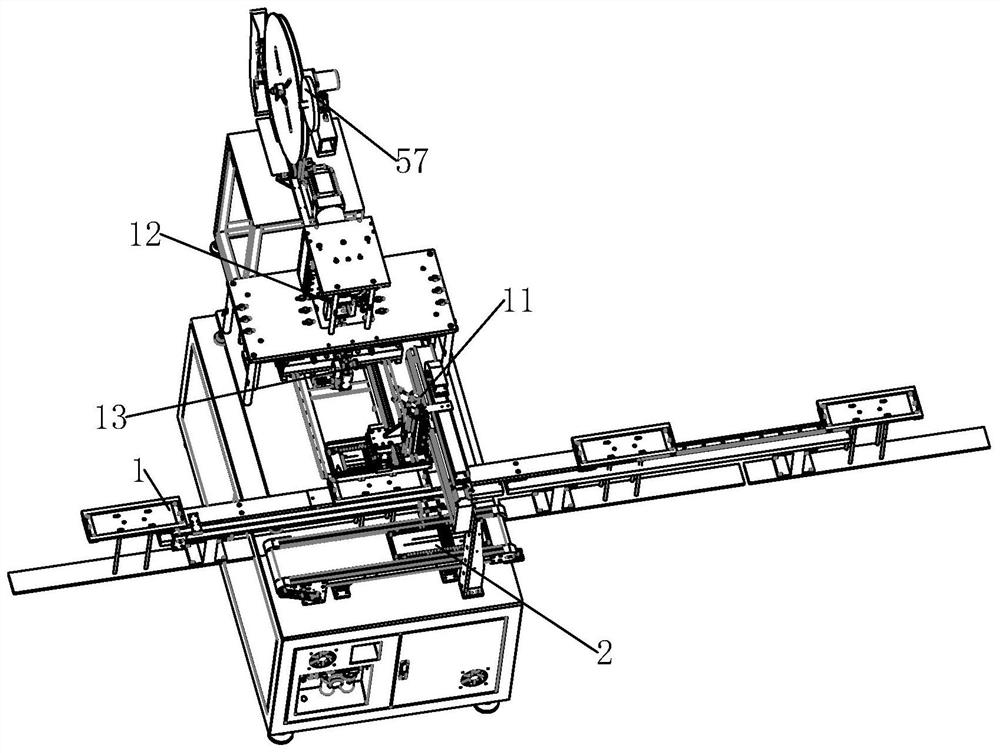

[0040] As one aspect of the present invention, a fully automatic riveting machine is provided, including: a carrier plate conveying mechanism 1 arranged in parallel, and a carrier plate return mechanism 2, and the carrier plate conveying mechanism 1 is sequentially provided with laser mid-stripping Device 3, iron buckle device 4, electric measuring device 5, visual detection device 6.

[0041] Wherein, the laser middle stripping device 3 includes a first carrier board pick-and-place mechanism 7, a laser wire stripping mechanism 8, and a carrier board transfer XY mechanism 9, and the first carrier board pick-and-place mechanism 7 transfers the carrier board conveying mechanism 1 The carrier board 10 on the top moves to the carrier board transfer XY m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com