A bar cold shear conveying production line and its control system

A control system and production line technology, which is applied in the direction of automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of inability to guarantee the consistency of bar cut surfaces, inability to realize power relay, disordered bars, etc., and achieve process Simplicity, improved stability, and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

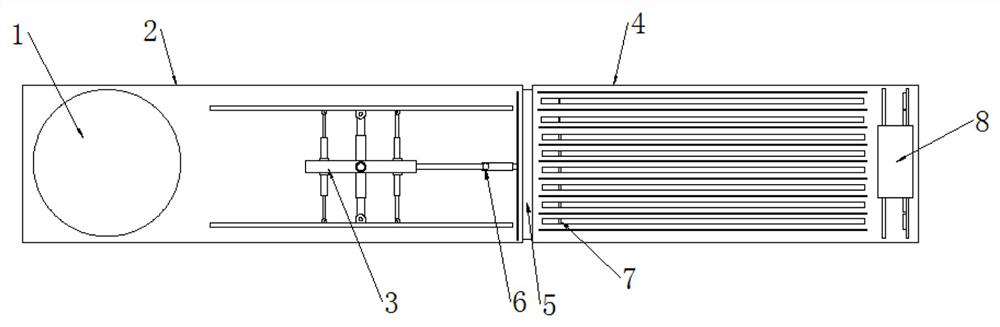

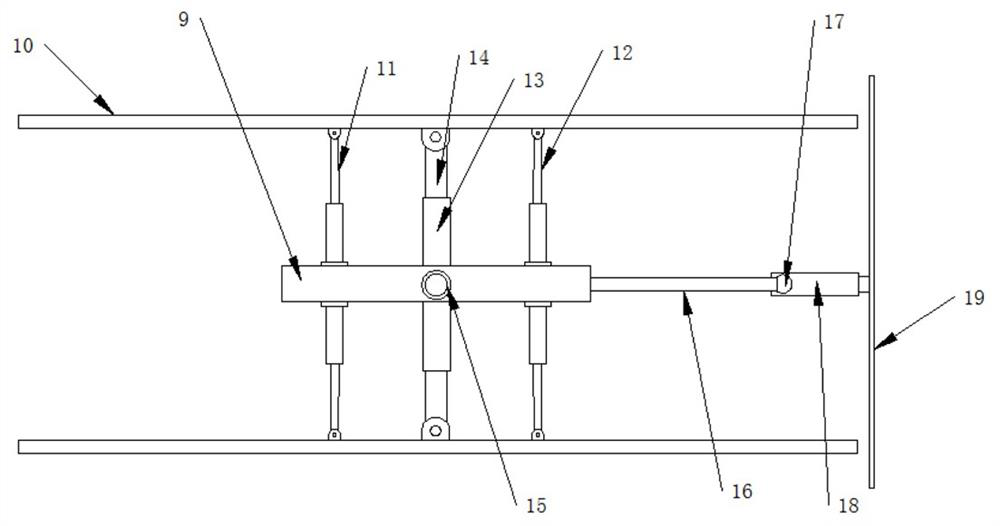

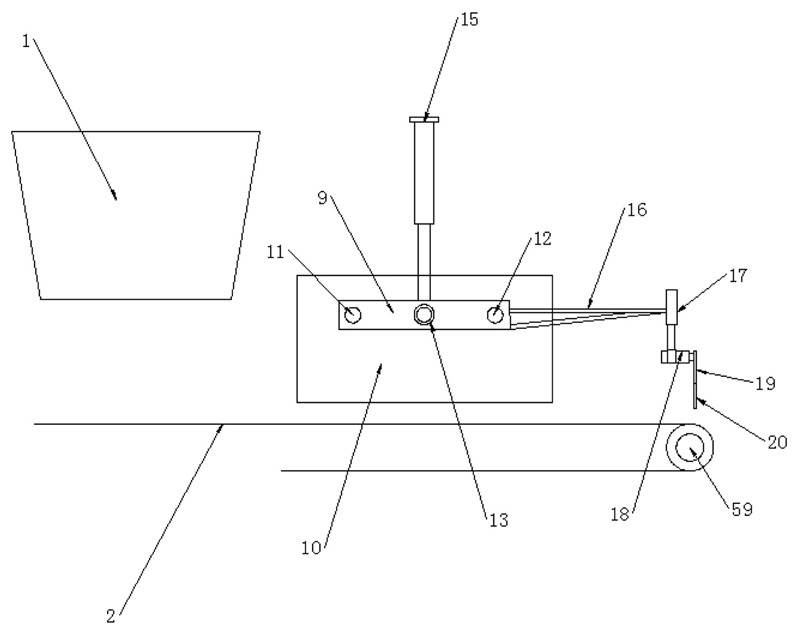

[0085] Such as Figure 1 to Figure 9 As shown, the bar material cold shearing conveying production line includes a receiving conveyor 2 located below the hopper 1, a bar guiding device 3 is provided above the receiving conveyor 2, and a cutting device is provided at the discharge end of the receiving conveyor 2. Supporting platform 4, a transition connecting device 5 is provided between the cutting support platform 4 and the receiving conveyor 2, and a bar on the receiving conveyor 2 is provided above the receiving conveyor 2 to the cutting support platform 4. The power relay device 6 is provided with a bar materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com