Glass fiber reinforced plastic chemical tank manufacturing and forming method

A molding method and technology of chemical tanks, which are applied in the direction of manufacturing tools, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem of affecting the grinding effect, the fixed height cannot be adjusted, the manufacturing molding rate and low practicability and other issues to achieve the effect of increasing the scope of application and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

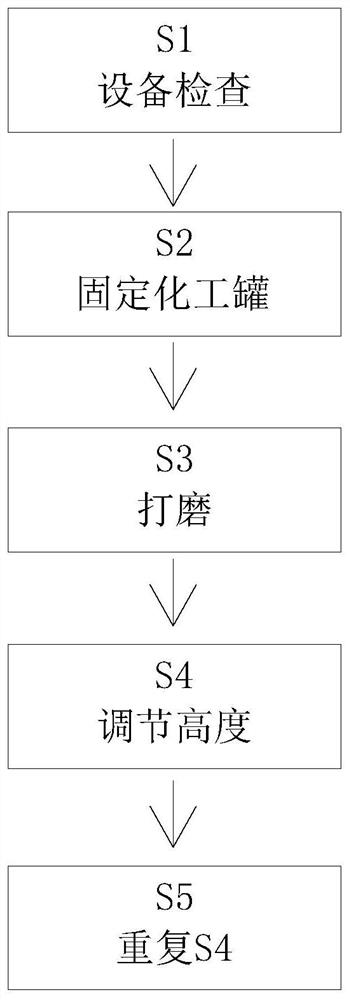

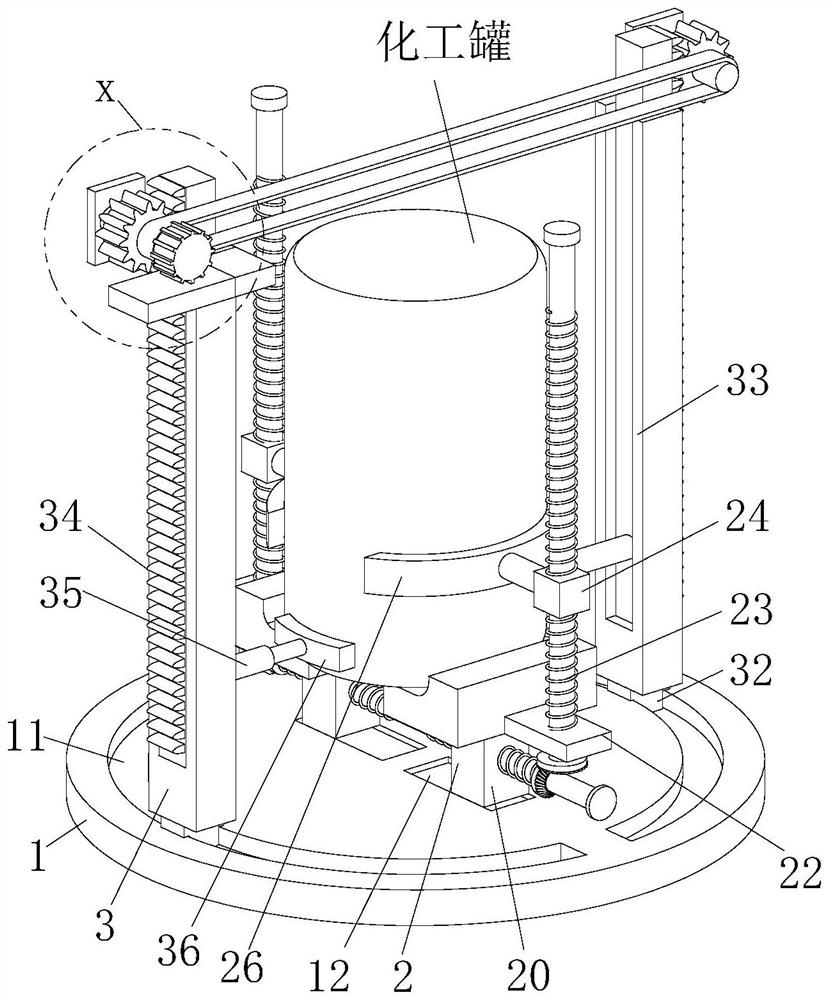

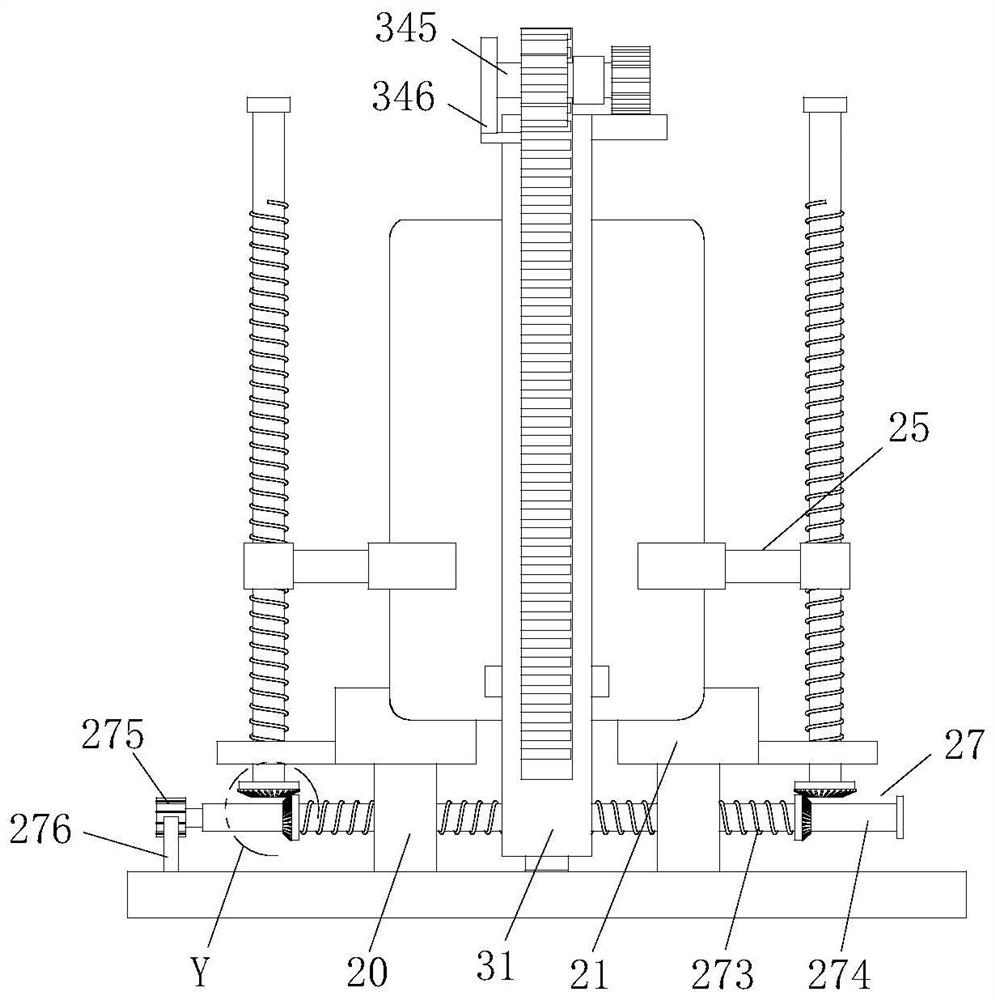

[0033] like Figure 1 to Figure 7 As shown, a method for manufacturing and molding a glass-steeled chemical tank, the manufacturing and molding method for a glass-steeled chemical tank adopts the following equipment for manufacturing and molding, the equipment includes a base 1, a fixing device 2 and a polishing device 3, and the base 1 is disc-shaped , the lower end of the base 1 is connected to the existing ground, the upper end of the base 1 is provided with a fixing device 2 , and the front and rear sides of the fixing device 2 are symmetrically provided with a polishing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com