EPE foaming pearl wool lining packaging material and manufacturing and processing method thereof

A packaging material, pearl cotton technology, applied in the direction of transportation and packaging, containers and containers to prevent mechanical damage, can solve the problems of high labor intensity, low sorting efficiency, affecting the progress of the molding process, and save time and cost. , the effect of simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 12 , to further elaborate the present invention.

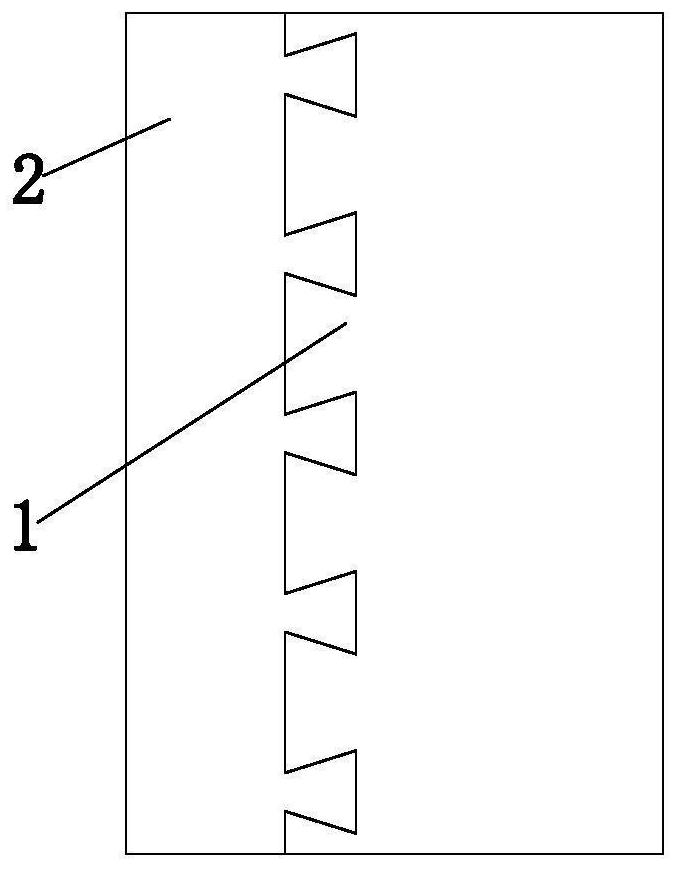

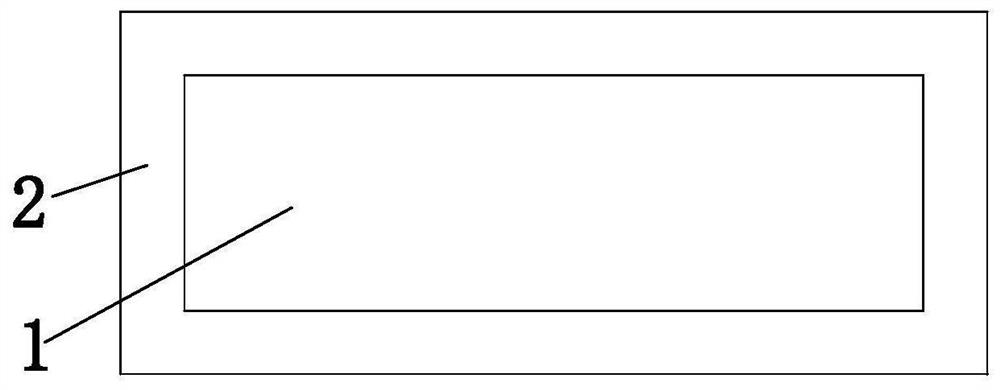

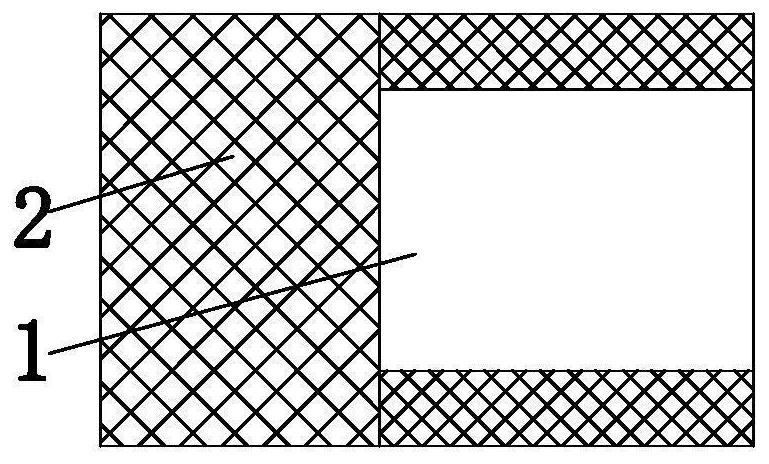

[0042] An EPE foamed pearl cotton-lined packaging material, comprising a supporting plate 1 and a clamping plate 2, the right end of the supporting plate 1 is evenly opened with a plurality of No. There are multiple No. 2 snap-in grooves. The No. 1 snap-in slot and the No. 2 snap-in slot are arranged alternately in front and back. The right end of the pallet 1 and the left end of the pallet 2 are snapped together by concave-convex cooperation. The snap slots, No. 1 snap slot and No. 2 snap slot are isosceles trapezoidal structures, and the opening sizes of No. 1 snap slot and No. 2 snap slot are gradually increasing from outside to inside to prevent Relative sliding occurs between the pallet 1 and the clamping board 2; where:

[0043] In the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com