Lifting type charging device, charging pile and lifting type charging device motion control method

A charging device and motion control technology, applied in electromechanical devices, charging stations, electric vehicles, etc., can solve the problems of large contact impact force and large contact impact force of positive and negative electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

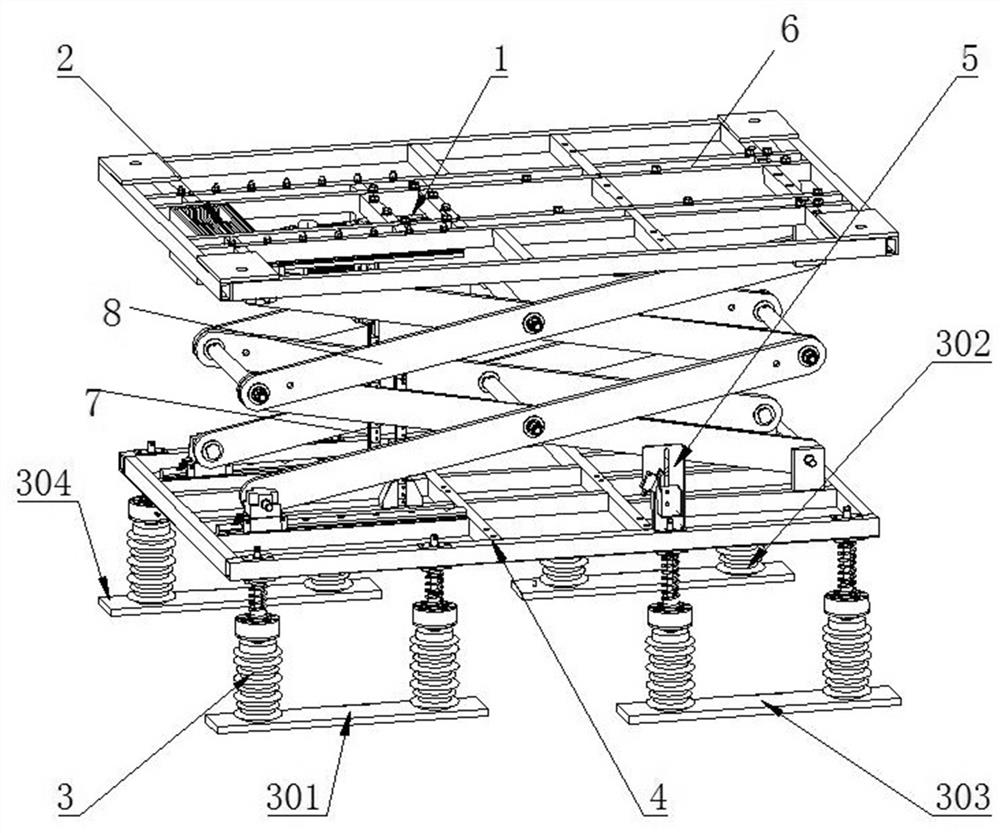

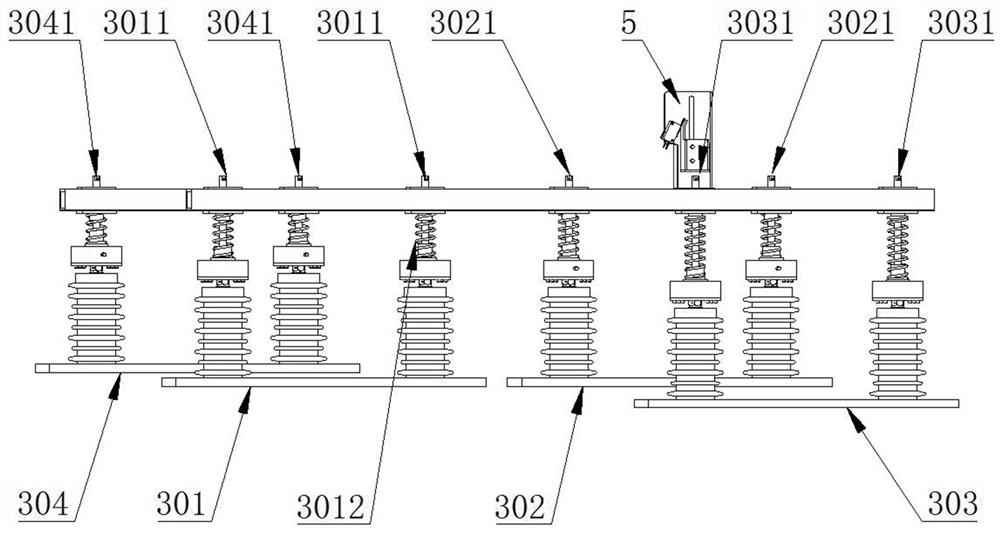

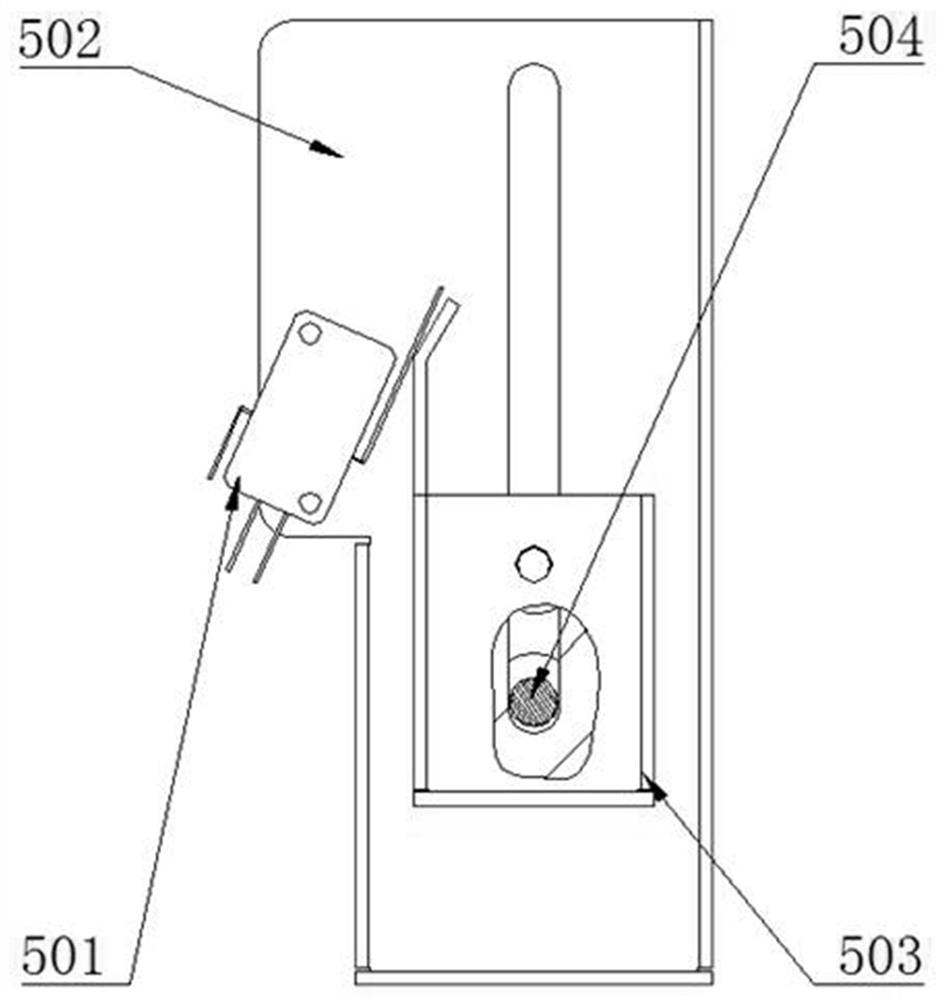

[0048] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0049] In the existing lifting charging device, the power source drives the charging frame down through the lifting mechanism to realize the charging operation, and it rises and retracts when the charging is completed. Usually, in order to save charging preparation time, the charging frame falls faster, which leads to falling. The impact force is greater, and the greater impact force will accelerate the wear of the electrodes. This wear has a particularly large impact on the charging positive electrode and charging negative electrode that pass through a large current. In order to prolong the service life of the charging positive electrode and charging negative electrode, the present invention provides corresponding The motion control method and the lifting charging device are used to reduce the shock effect when the charging positive pole and the charging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com