Method and device for starting engine in dual-motor hybrid power system, and vehicle

A hybrid power system and engine starting technology, applied in the field of vehicles, can solve problems affecting the smoothness and safety of engine starting, engine speed drop, starting shock, etc., so as to improve the starting smoothness, avoid disturbance shock, and ensure response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

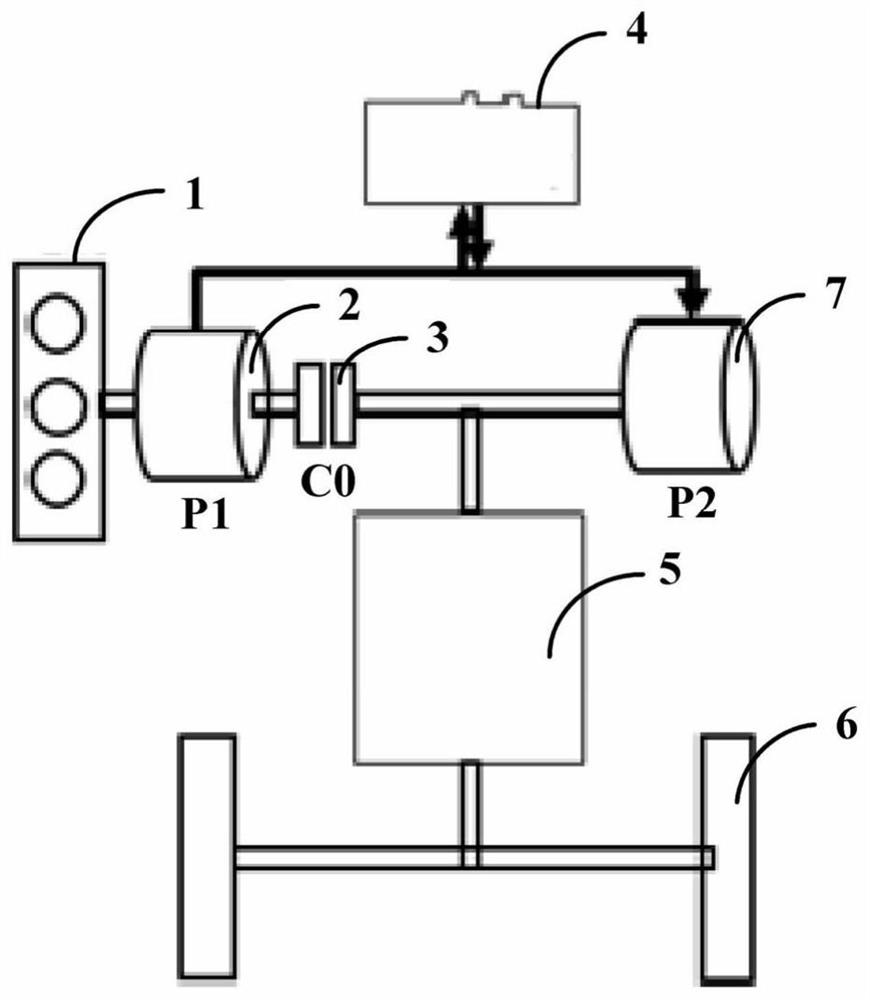

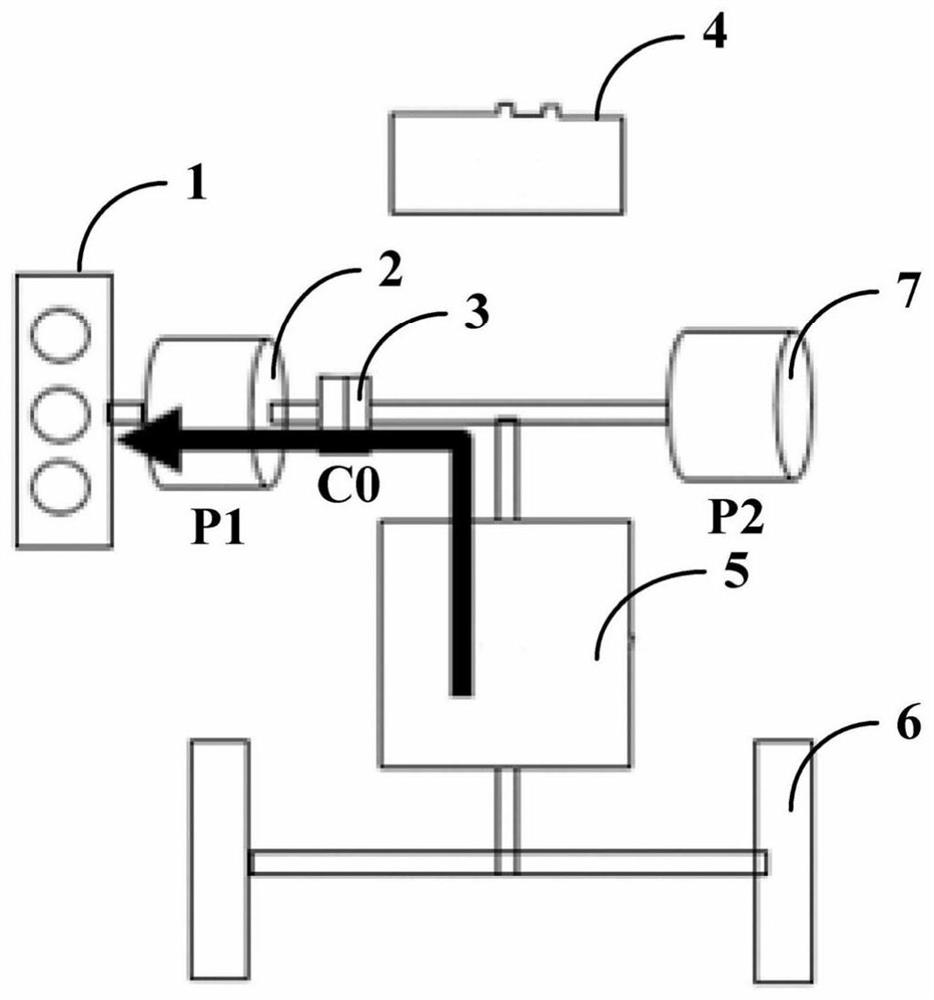

[0065] The structure of the dual-motor hybrid system in this embodiment is as follows: figure 1 As shown, it includes an engine 1 , a first motor 2 connected to the engine 1 (namely the P1 motor), and a clutch 3 connected between the first motor 2 and the transmission system 5 (namely the clutch C0 ).

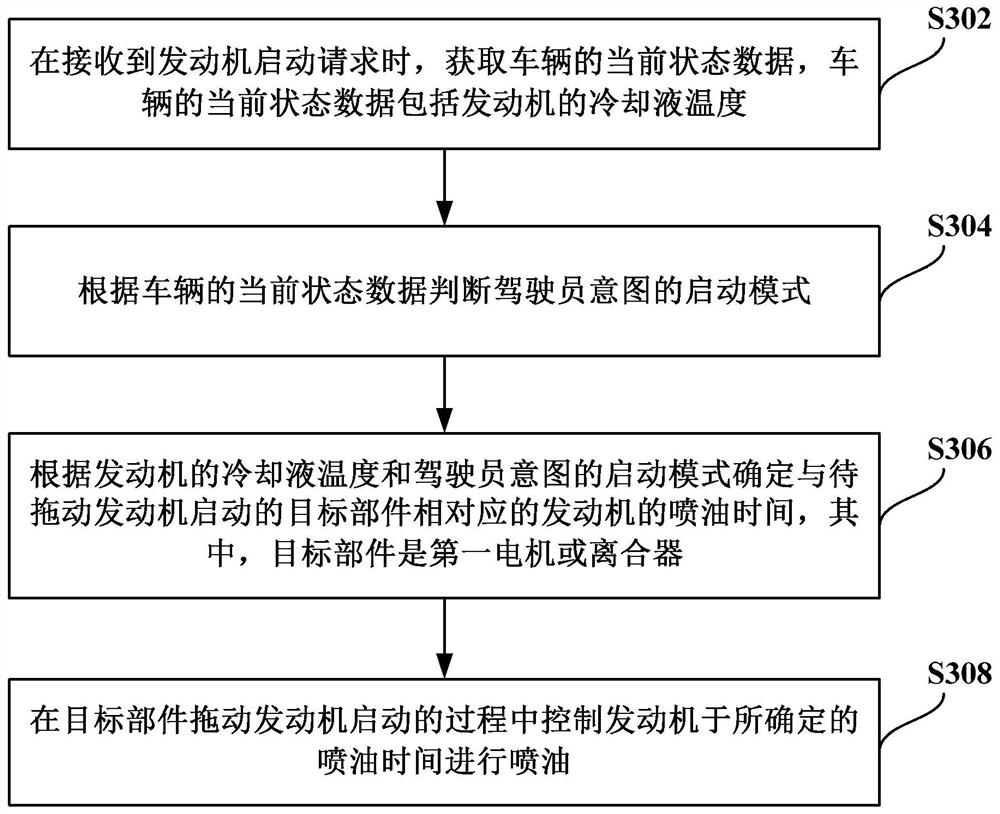

[0066] see image 3 As shown, the method for starting the engine in the dual-motor hybrid system of this embodiment may at least include the following steps S302 to S308.

[0067] Step S302, when the engine start request is received, the current state data of the vehicle is obtained, the current state data of the vehicle includes the coolant temperature of the engine 1 (usually the coolant temperature of the engine 1).

[0068] Step S304, judging the activation mode intended by the driver according to the current state data of the vehicle.

[0069] Step S306, according to the coolant temperature of the engine 1 and the starting mode of the driver's intention, determine the fu...

Embodiment 2

[0101] The difference between this embodiment and Embodiment 1 is that in the process of starting the engine 1 driven by the target component (the first motor 2 or the clutch 3), not only the fuel injection time of the engine 1 is targetedly controlled, but also the target component Execute a pre-drag torque strategy.

[0102] refer to Figure 4 As shown, the method for starting the engine in the dual-motor hybrid system of this embodiment may at least include the following steps S402 to S412.

[0103] Step S402, when the engine start request is received, the current state data of the vehicle is obtained, wherein the current state data of the vehicle at least includes the engine 1 speed and the coolant temperature of the engine 1 (usually the coolant temperature of the engine 1).

[0104] Step S404, judging the activation mode intended by the driver according to the current state data of the vehicle.

[0105] Step S406, judging whether the pre-drag torque application conditi...

Embodiment 3

[0121] The difference between this embodiment and Embodiment 1 is that before starting the engine 1, it is first judged whether the waiting clutch start strategy can be enabled, so that even if there is an engine start request when the P1 motor fails and the vehicle speed is less than or equal to the preset vehicle speed threshold, the Instead of starting with 12V, the clutch is activated when the vehicle speed increases to a value greater than the preset vehicle speed threshold to meet the vehicle speed condition for clutch activation.

[0122] refer to Figure 8 As shown, the method for starting the engine in the dual-motor hybrid system of this embodiment may at least include the following steps S802 to S816.

[0123] Step S802, when the engine start request is received, the current state of the first electric machine 2 is obtained.

[0124] Step S804, if the current state of the first motor 2 is failure, then obtain the current state data of the vehicle, the current state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com