High-temperature high-chlorine-resistance reactive red dye for cotton and preparation method thereof

A technology of red dyes and reactive dyes, which is applied in the field of reactive red dyes for high-temperature chlorine-resistant cotton and its preparation. It can solve the problems of poor chlorine resistance stability, active chlorine oxidation damage, discoloration and other problems, and achieve improved chlorine resistance. The effect of increasing stability and improving the ability to resist available chlorine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

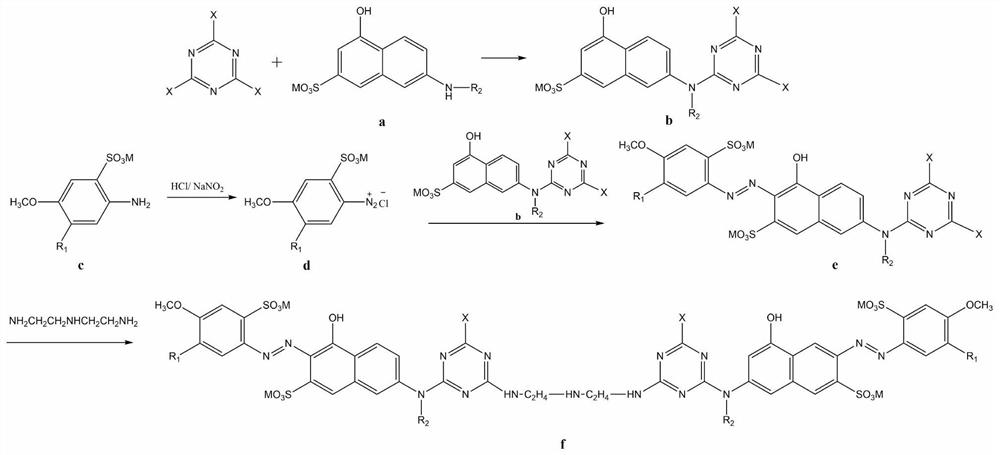

[0038] An embodiment provided by the present invention: a reactive red dye for high-temperature chlorine-resistant cotton, the reactive red dye is a compound shown in general structural formula I-1;

[0039]

[0040]

[0041] The preparation method of the compound shown in the above-mentioned general formula I-1 is carried out according to the following process, and the specific steps include:

[0042] (1) Preparation of J-acid X-type red reactive dyes

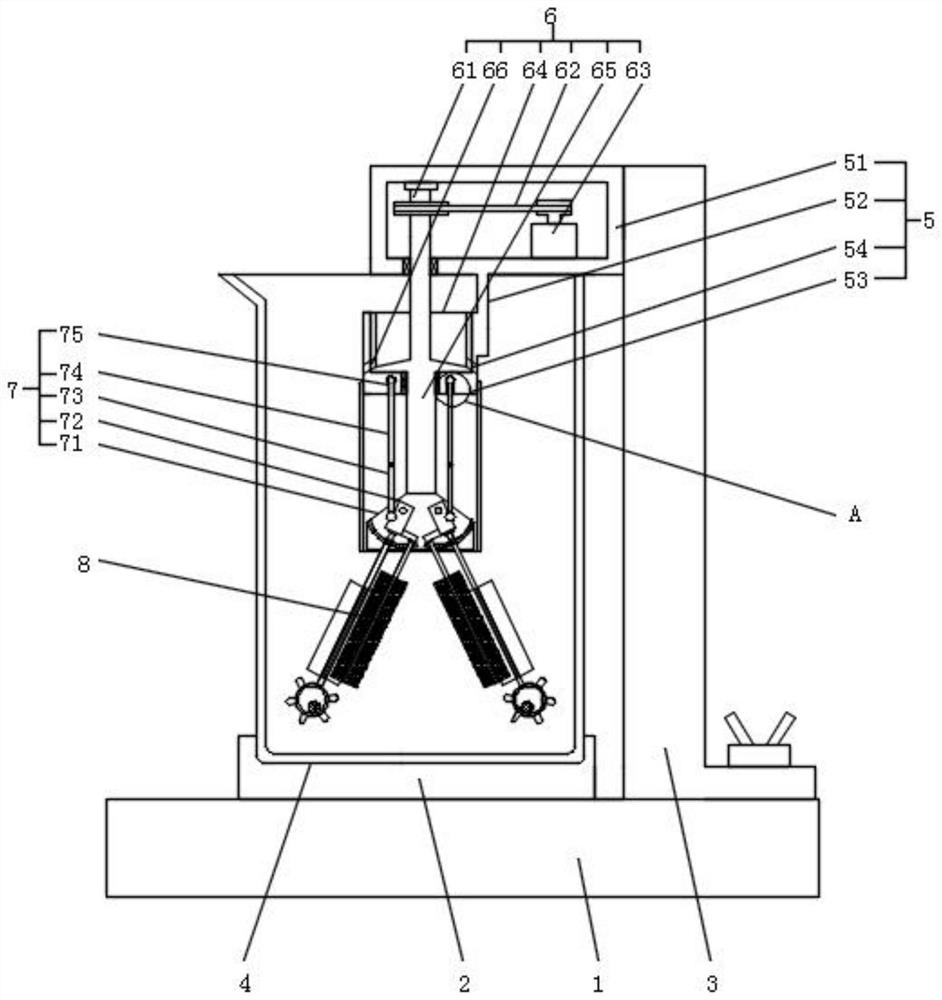

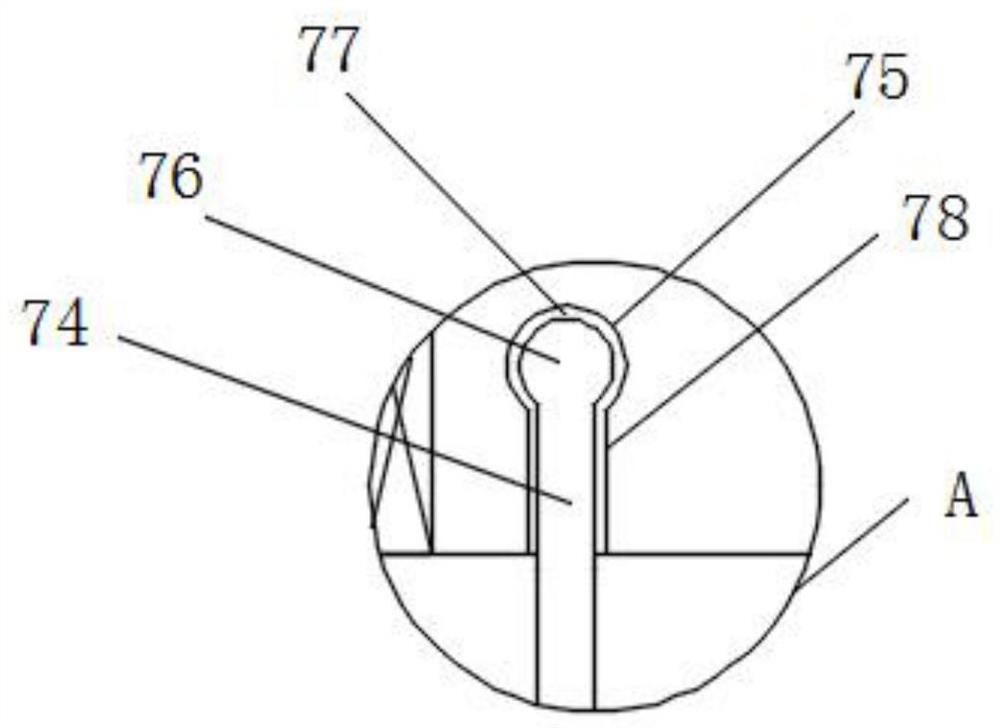

[0043] A1: Put 19.2g of 100% cyanuric chloride in the drum of the beating device, add 200g of ice and 20ml of water into a 1000ml beaker, then place the beaker under the beating device, and beat until viscous. Add 23.9g of 100% 2-amino-5-naphthol-7-sulfonic acid (J acid) and 600ml of water into a 1000ml beaker, adjust the pH of the system to about 6.8 with 15% NaOH solution, stir and dissolve, then slowly add the above In the beating solution of cyanuric chloride, control the reaction conditions at 0-5°C and pH=2-3, con...

Embodiment 2

[0052] An embodiment provided by the present invention: a reactive red dye for high-temperature chlorine-resistant cotton, the reactive red dye is a compound shown in general structural formula I-2;

[0053]

[0054] In the present embodiment, the preparation method of reactive dyes I-2 and the beating device in the A1 step of the preparation method of reactive dyes are the same as in Example 1, except that N-methyl J acid replaces J in I-1 preparation step A1 acid to prepare the corresponding reactive red dye, and reactive dye I-2 was used instead of reactive dye I-1 to prepare the corresponding commercial dye.

Embodiment 3

[0056]An embodiment provided by the invention: a reactive red dye for high-temperature chlorine-resistant cotton, the reactive red dye is a compound shown in general structural formula I-3:

[0057]

[0058] In the present embodiment, the beating device in the A1 step in the preparation method of reactive dyes I-3 and the preparation method of reactive dyes is the same as that of Example 1, except that p-aminoanisole-2,5-disulfonic acid replaces I- 1 The p-aminoanisole-2-sulfonic acid in the preparation step (1) was used to prepare the corresponding reactive red dye, and reactive dye I-3 was used instead of reactive dye I-1 to prepare the corresponding commercial dye.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com