Copper alloy for laser cladding valve sheet

A copper alloy and laser melting technology, applied in laser welding equipment, metal processing equipment, metal material coating technology, etc., can solve problems such as large hardness deviation, inability to effectively disperse stress, matrix structure and hard phase interface cracks, etc. To achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present disclosure will be described in detail. However, the present disclosure is not limited or restricted by the exemplary embodiments, and the objects and effects of the present disclosure will be naturally understood or become apparent from the following description, and the objects and effects of the present disclosure are not limited only by the following description. Also, in the description of the present disclosure, when it is determined that the detailed description of known technologies related to the present disclosure will unnecessarily obscure the gist of the present disclosure, the detailed description thereof will be omitted.

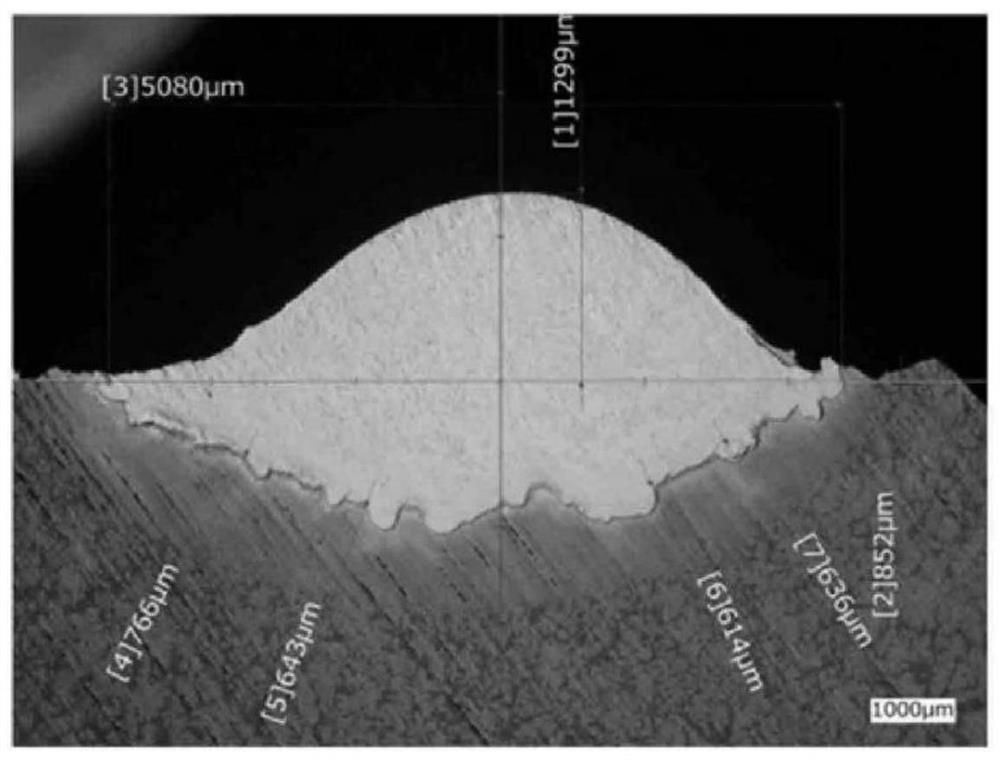

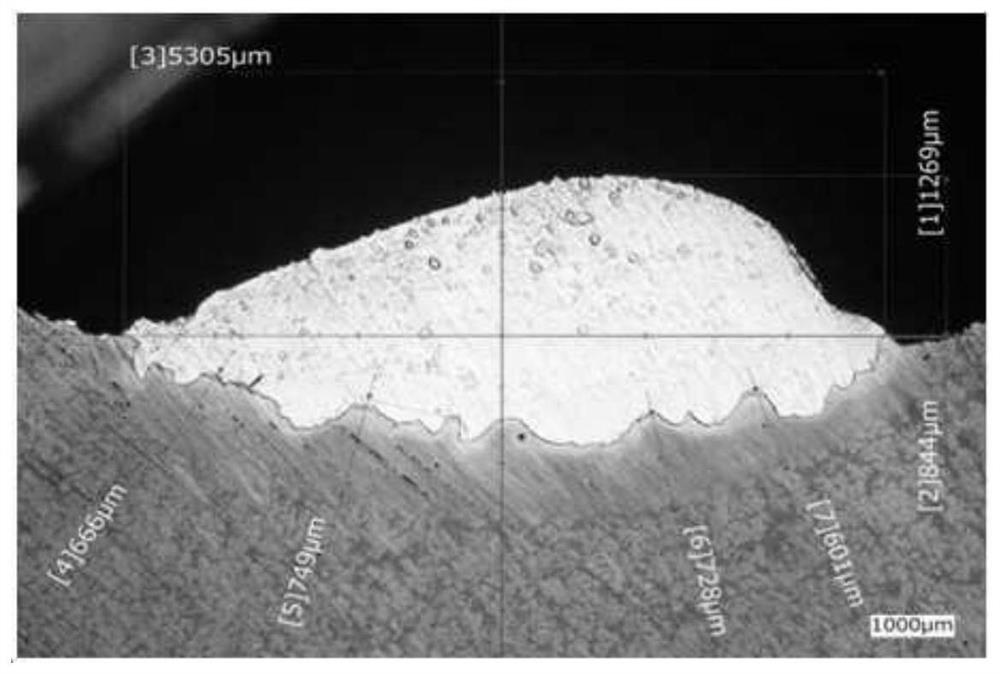

[0020] For the process of forming the matrix structure and the hard phase, the following description can be referred to. The quinary liquid phase single-phase Cu-Ni-Si-Fe-Mo is separated into a Cu-rich liquid phase (including a small amount of Si and N, hereafter referred to as the liquid phase L 1 ) and Fe-Mo-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com