A method for cleaning shaft furnace burner clogging

A cleaning method and technology for shaft furnaces, which are applied to furnaces, vertical furnaces, furnace types, etc., can solve the problems of impossible elimination of moisture and volatile impurities, large cleaning workload, and burner damage due to bumping, so as to achieve simple and convenient cleaning. , Less cleaning time, reducing the effect of burner sticking impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

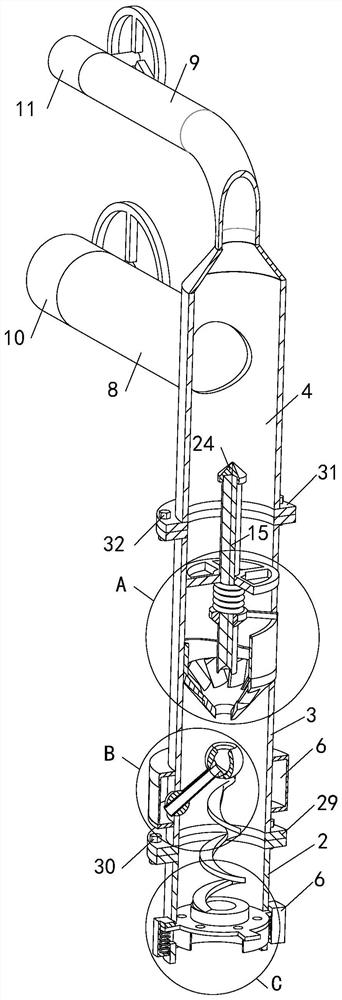

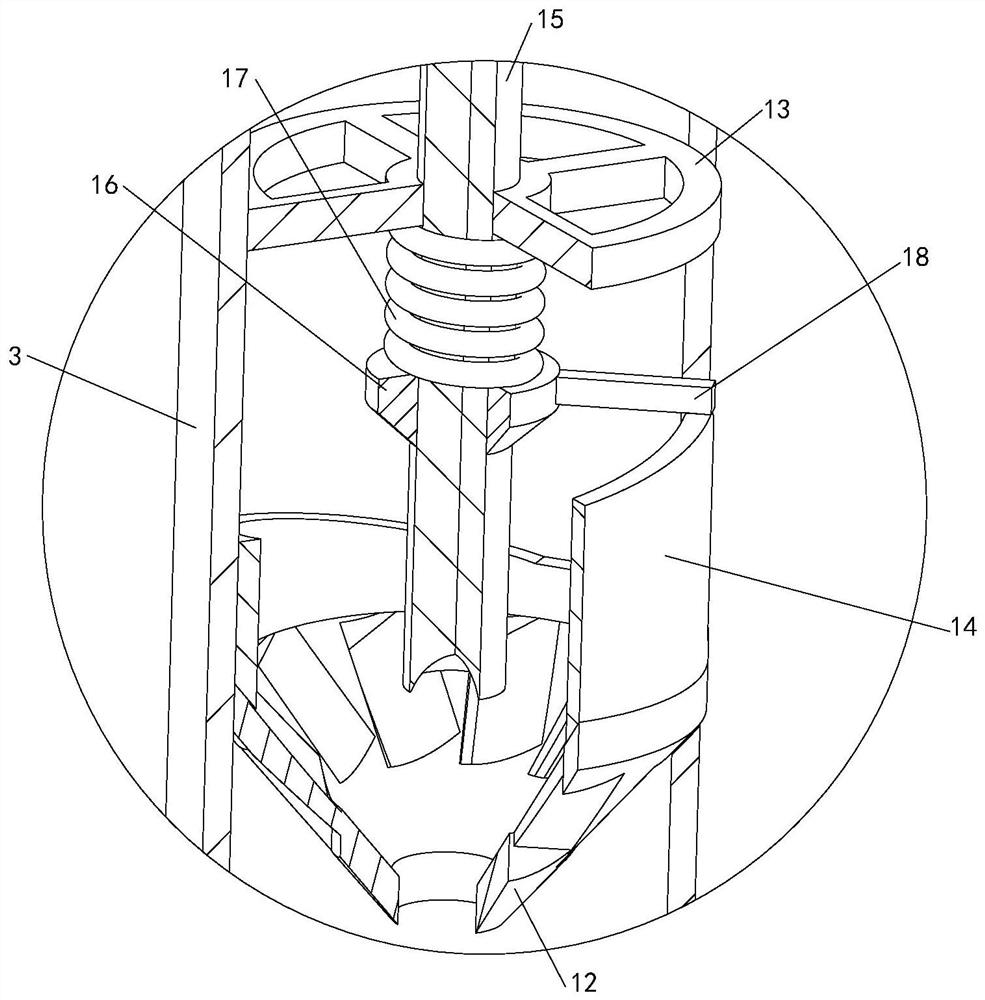

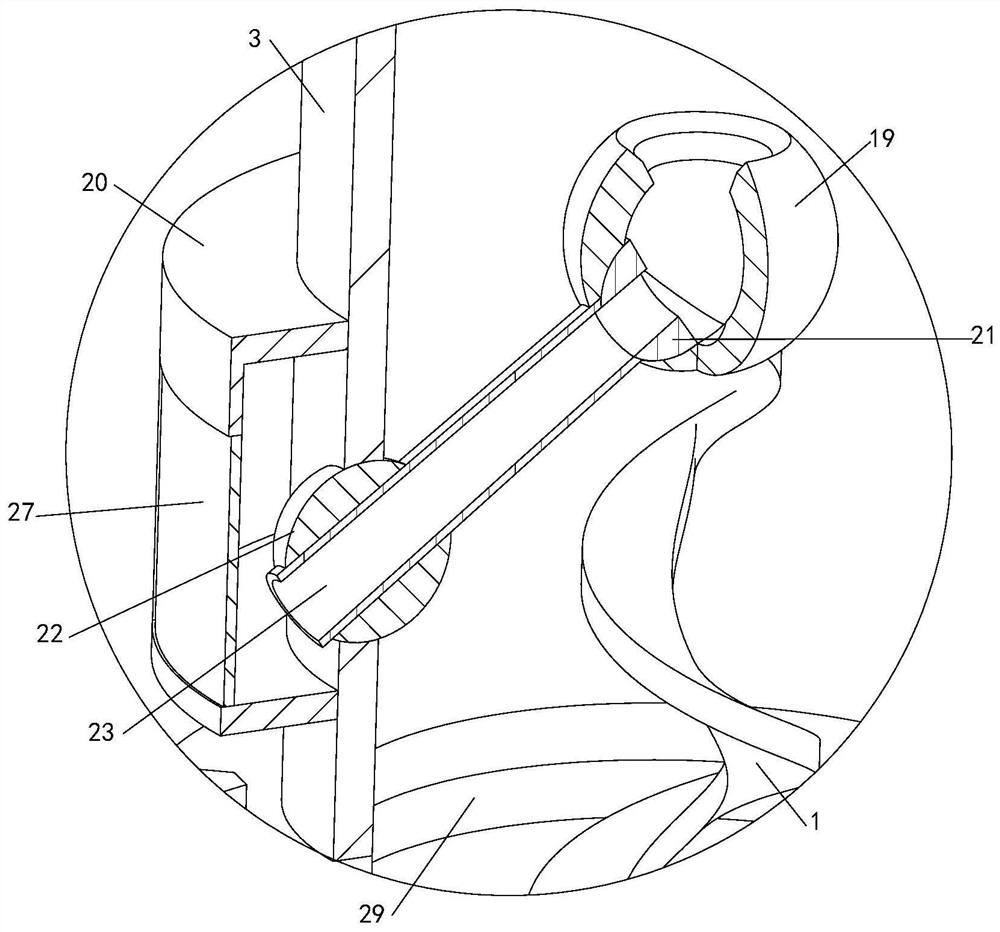

[0034] See Figure 1-8, a cleaning method of the vertical furnace burner blockage, the cleaning method of the vertical furnace burner blockage is based on a vertical furnace burner device to achieve, comprising a burner 1, further comprising a flame cylinder 2, an installation cylinder 3 and a gas supply cylinder 4, a flame cylinder 2 is connected to the mounting cylinder 3, a gas supply cylinder 4 is connected to the mounting cylinder 3, and the gas supply cylinder 4 is connected to the flame cylinder 2 by the mounting cylinder 3, the flame cylinder 2 is connected with a round fin 5, and the flame cylinder 2 is externally fixed to have multiple ear cups that match the round fin 5, Multiple ear cups 6 and round fin 5 are fixed connection elastic spring 7, burner 1 and round fin 5 connected, mounting cylinder 3 is installed with ash suppression mechanism, easy to burner 1 of the impact vibration, thereby facilitating the reduction of burner 1 adhesion impurities, and thus easy to av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com