Novel electric moving and fixing device

An electric and new type of technology, applied in the field of new electric solidifiers, can solve problems such as poor accuracy, and achieve the effects of high reliability, simple sampling process and high weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

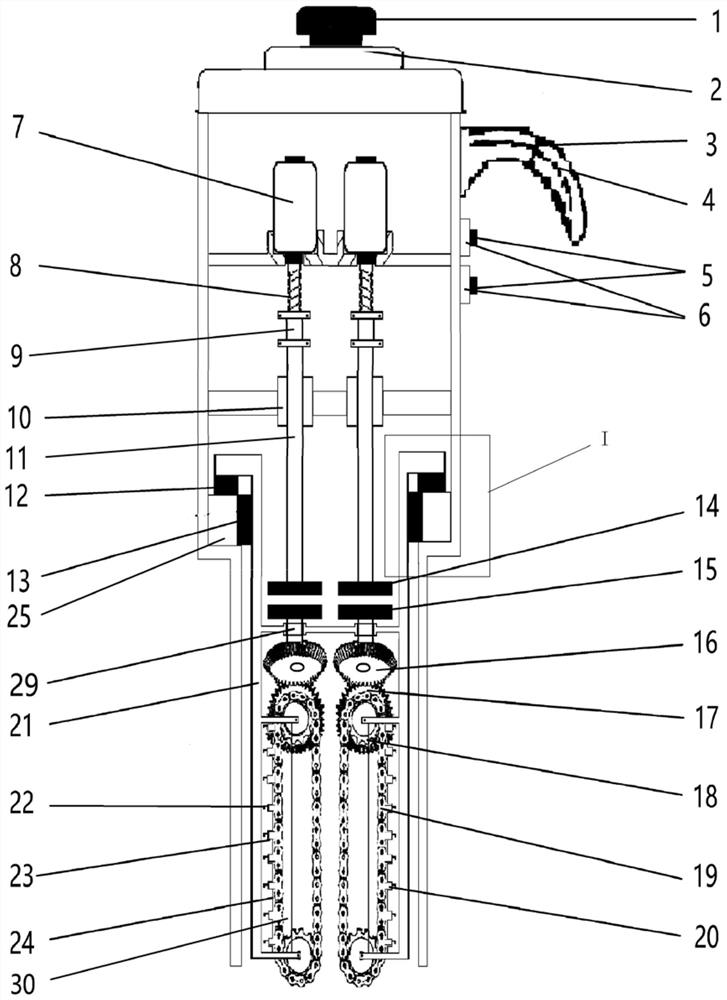

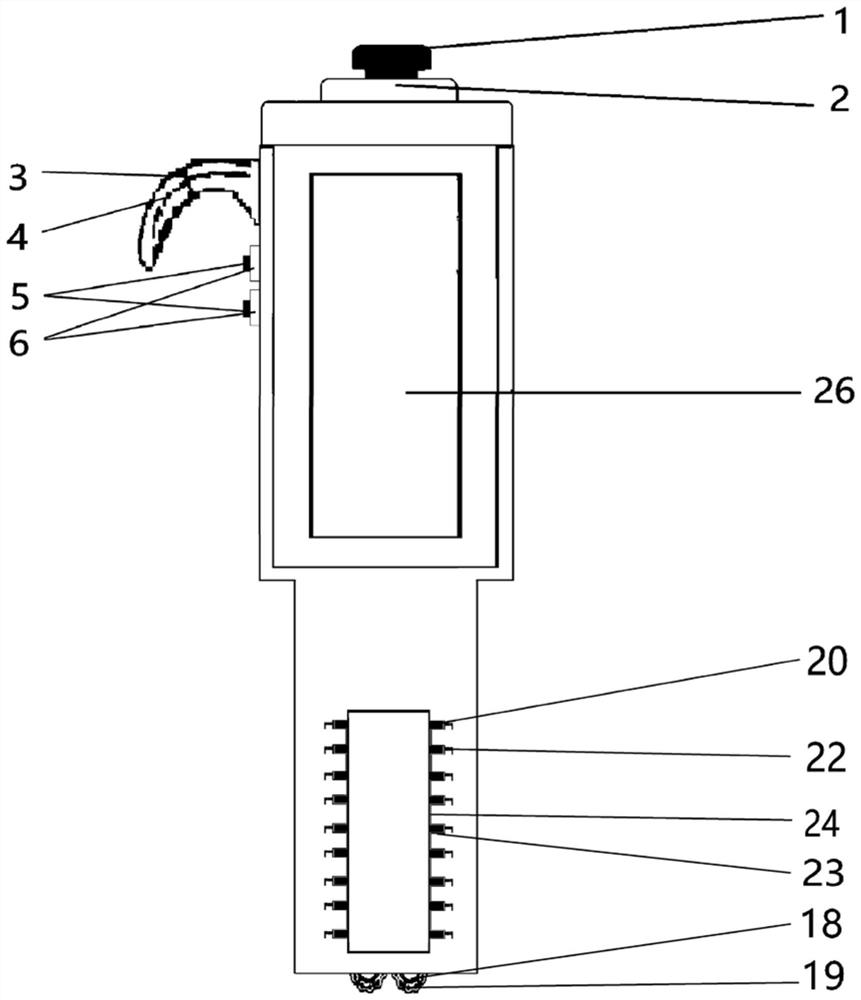

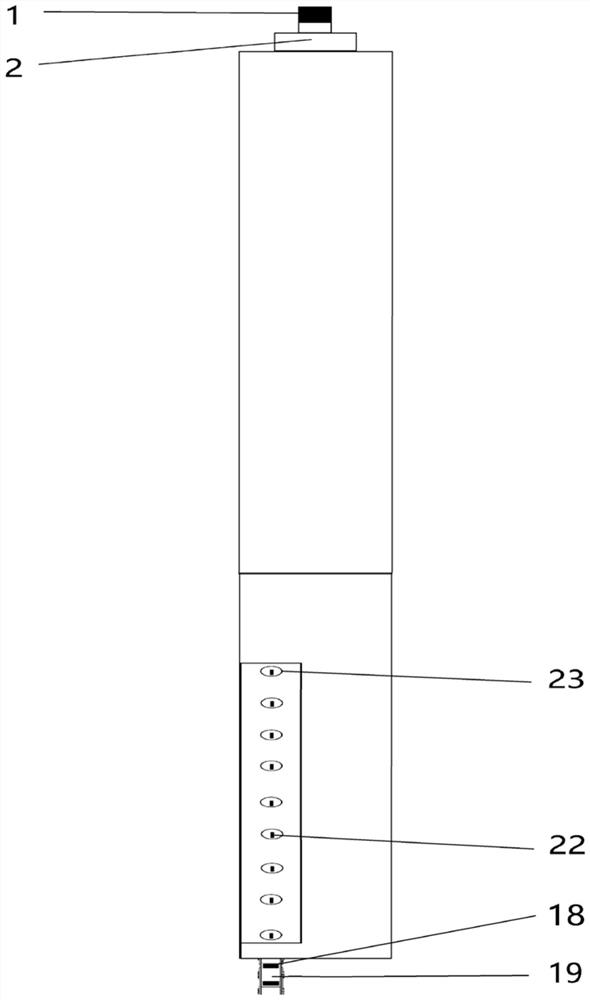

[0030] Such as Figure 1-7 As shown, a new type of electric solid transfer device, including a magnetic drive system, a shock-absorbing weighing system, an operating system, a support frame and a sampling mechanism;

[0031] Described magnetic driving system comprises driving motor 7, power transmission shaft 11, magnetic force transmission head 14, magnetic force driven head 15 and sprocket transmission system to form; The end of the shaft 11 is provided with a magnetic drive head 14, and a magnetic driven head 15 is provided below the magnetic drive head 14, and the magnetic driven head 15 is connected with the sprocket transmission system; two sets of magnetic drive systems are arranged side by side inside the housing;

[0032] The magnetization directions of the magnetic drive head 14 and the magnetic driven head 15 are opposite, and the drive is driven by the mutual attraction of the magnetic force, which can be directly driven without contact, and the interface contact f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com