Force measuring device suitable for extreme multi-factor coupling environment

A measuring device and multi-factor technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as high cost, measurement error, and imperceptibility, and achieve reliability problems, high force measurement accuracy, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

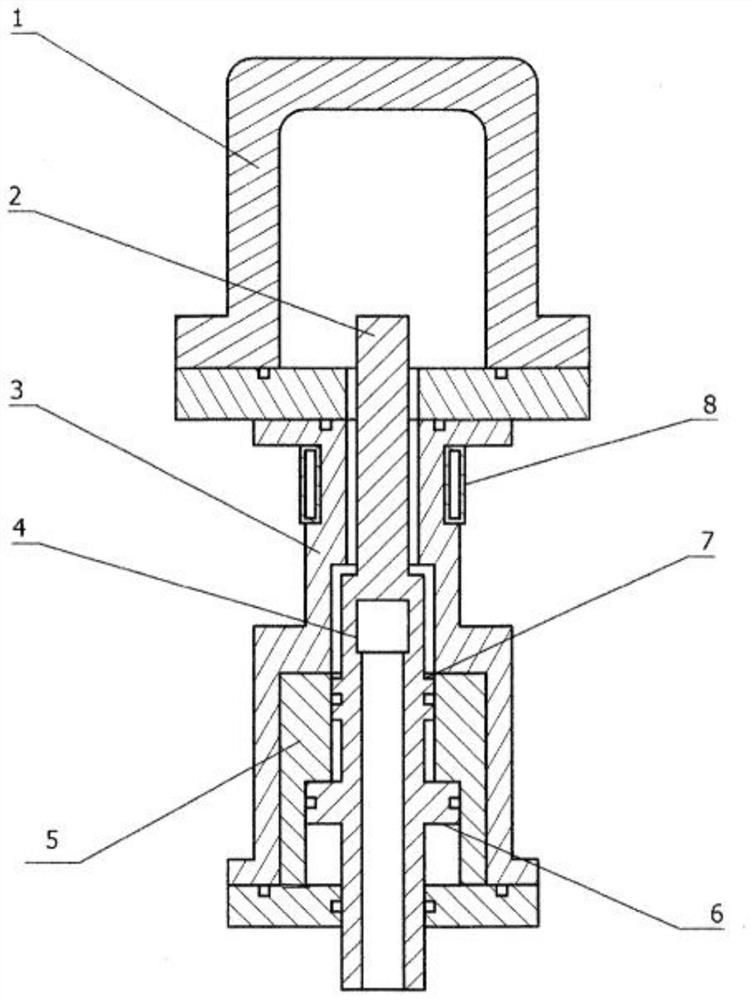

[0025] Attached below figure 1 and specific embodiments to further elaborate the technical solution of the present invention.

[0026] In order to evaluate the service safety of metal materials working in an extreme multi-factor coupling environment such as ultra-high temperature, ultra-high pressure corrosive water or steam environment, the samples are placed in a closed container such as an autoclave in a high temperature and high pressure corrosive water or steam environment. mechanical performance test, figure 1 Shown is a schematic diagram of the testing machine working in the environment of ultra-high temperature and ultra-high pressure corrosive water or steam.

[0027] see figure 1 As shown, the testing machine includes an autoclave (1), and its inner cavity is a high-temperature, high-pressure corrosive water or steam environment chamber, and the force measuring device includes:

[0028] One end of the jacket (3) is connected to the bottom end of the autoclave (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com