Method for measuring three-dimensional contact force of tail end of mechanical hand of teleoperation robot

A technology of a teleoperated robot and a measurement method, which is applied in the field of force parameter determination of a teleoperated robot manipulator, can solve the problems of difficult assembly, high power consumption, low sensitivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

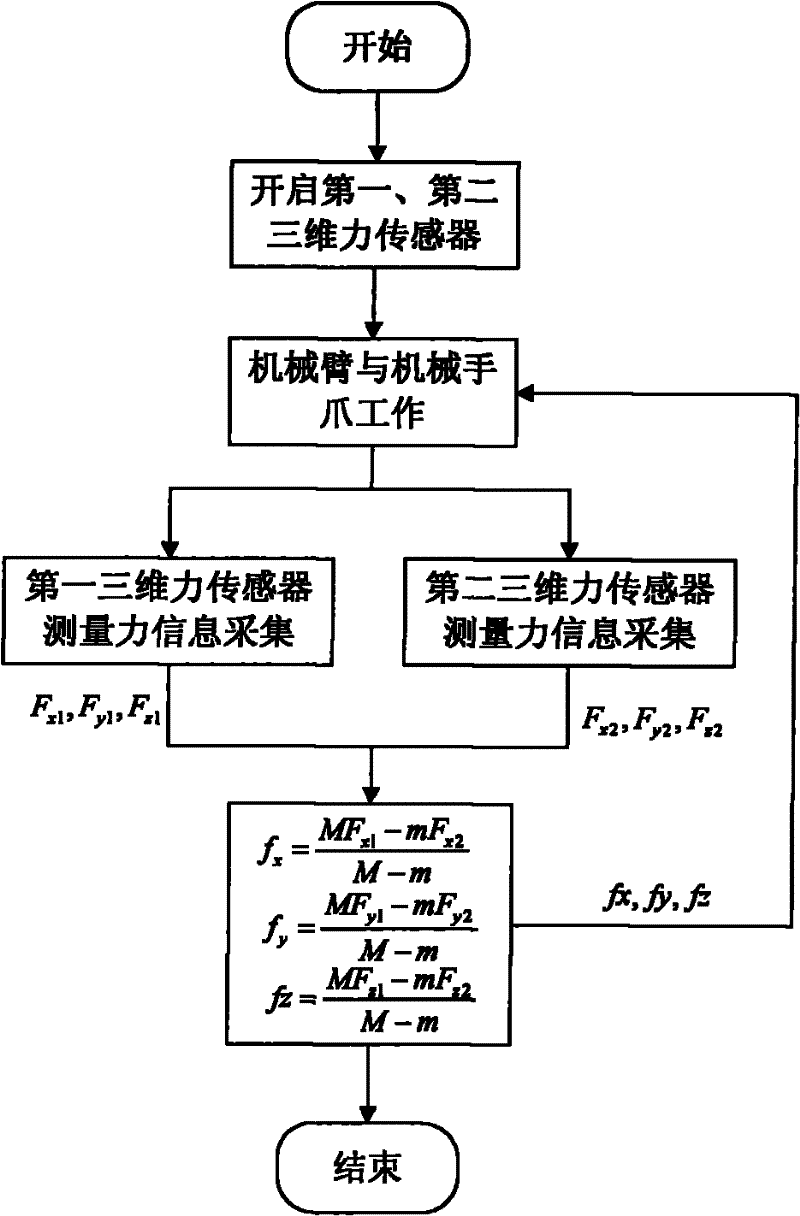

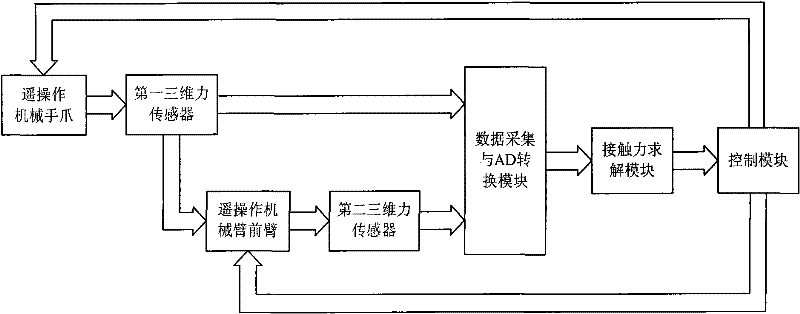

Method used

Image

Examples

Embodiment Construction

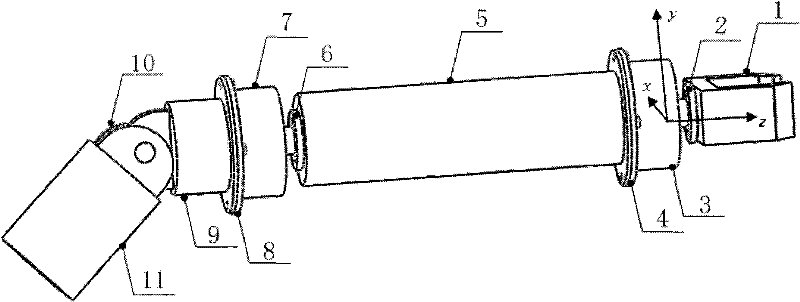

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] refer to figure 2 , is a telepresence remote operation robot manipulator device, and its main task is to carry out operations such as object grasping in extreme environments such as high temperature, high pressure, strong radiation, and suffocation that are difficult for people to approach. It includes a teleoperation manipulator gripper 1, a first three-dimensional force sensor 3, a teleoperation manipulator forearm 5, a second three-dimensional force sensor 7, a teleoperation robot elbow joint 10 composed of a hinge, and the second three-dimensional force sensor is fixed between the hinge and the forearm. The base 9 of the force sensor and the rear arm 11 of the teleoperated mechanical arm. The first three-dimensional force sensor 3 is fixed to the front end of the forearm 5 of the teleoperated manipulator through the flange plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com