Full-immersion type self-circulation evaporative cooling vehicle-mounted fuel cell system and working method thereof

A fuel cell system, evaporative cooling technology, used in clean energy applications and transportation, and can solve problems such as explosion, mixing, leaks in sealed passages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

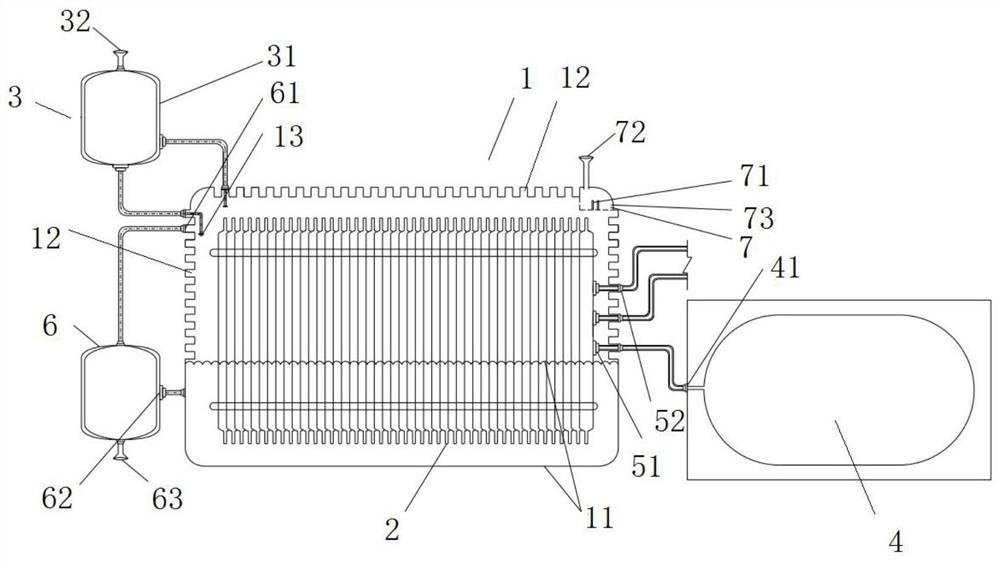

[0030] Referring to the accompanying drawings, it can be seen that the vehicle-mounted fuel cell system of full-immersion self-circulation evaporative cooling is characterized in that it includes a metal sealed box 1 filled with evaporative cooling medium, a fuel cell stack 2 located in the metal sealed box 1, and the metal sealed box 1 The liquid level supply device 3 connected to the top of the left side, and the hydrogen storage tank 4 connected to the right side of the metal sealed box 1;

[0031] The lower part of the metal sealed box 1 has a windshield 11, and the upper part and the top are heat dissipation structures 12;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com