Method for improving internal heat distribution consistency of water-cooled proton membrane fuel cell stack

A fuel cell stack, heat distribution technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as reducing the performance and life of the stack, affecting the operation of the stack, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

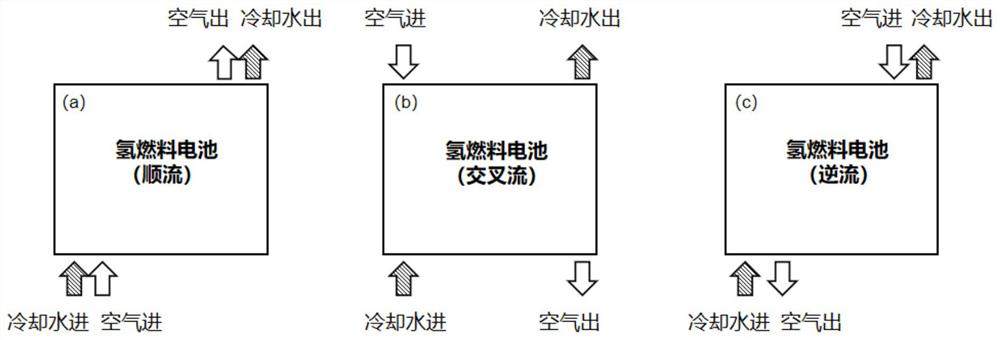

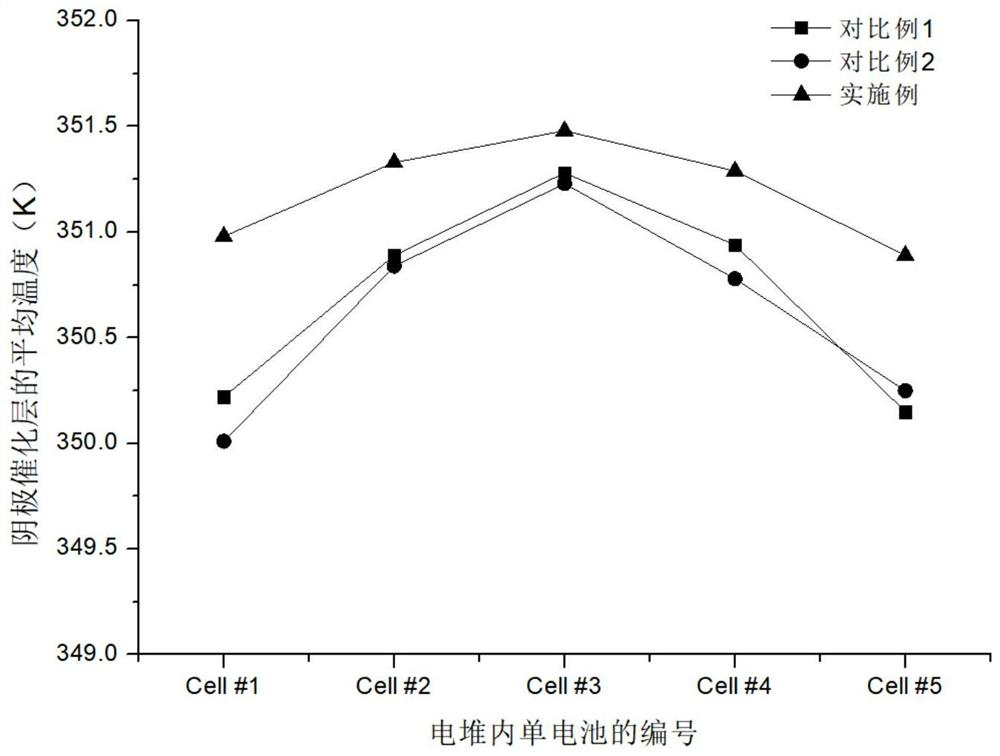

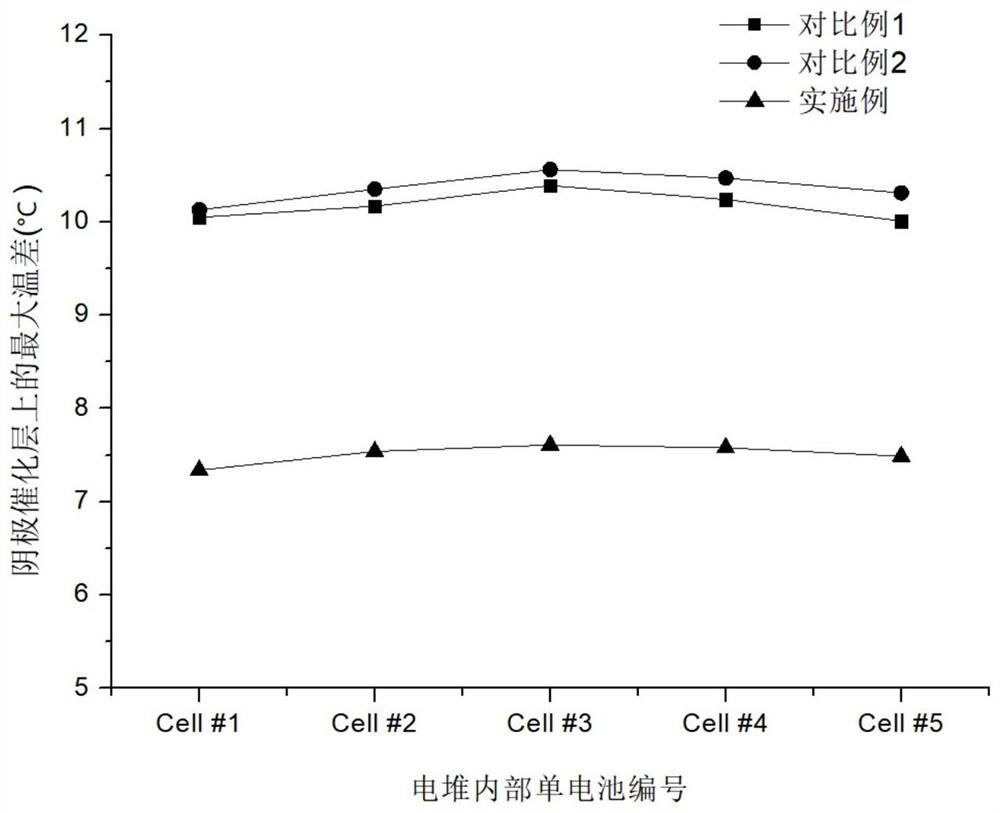

[0024] The embodiment is to arrange the cooling water and the air flow field in countercurrent, so as to improve the uniformity of heat distribution inside the electric stack. The flow field arrangement of embodiment is as figure 1 As shown, the air flow field and the cooling water flow field are arranged countercurrently, the air inlet and the cooling water outlet are on the same side, and the air outlet and the cooling water inlet are on the other side. The flow field structure of hydrogen is the same as that of air, but the direction of flow is opposite, that is, the flow fields of each other are arranged countercurrently. Under the same test operating conditions, the stack temperature distribution was compared between the embodiment and the three flow field arrangements of Comparative Examples 1 and 2. The test operating conditions are shown in Table 1 below. The results of embodiment and comparative example 1 and comparative example 2 are as figure 2 and image 3 show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com