Punching and pesticide applying integrated machine for improving soil with interlayer

An all-in-one machine and soil technology, applied in the direction of soil lifting machinery, application, transplanting machinery, etc., can solve problems such as lack of integrated equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

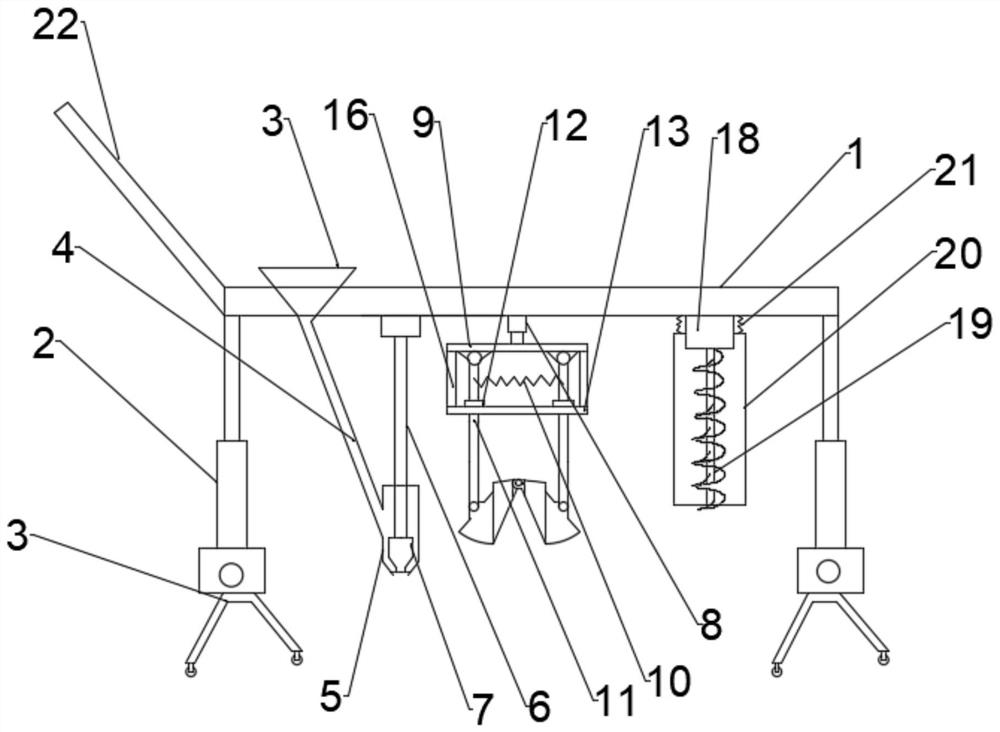

[0036] Such as figure 1 As shown, this embodiment provides an all-in-one punching and spraying machine for improving interlayer soil, including: a support platform 1, the bottom of the support platform 1 is provided with a fertilization device, a transplanting device and a hole-punching device. Both ends of the bottom of the support platform 1 are provided with telescopic moving devices.

[0037] The equipment integrates drilling, transplanting and fertilization, and is suitable for soils with different hardness, improving work efficiency and saving labor costs.

Embodiment 2

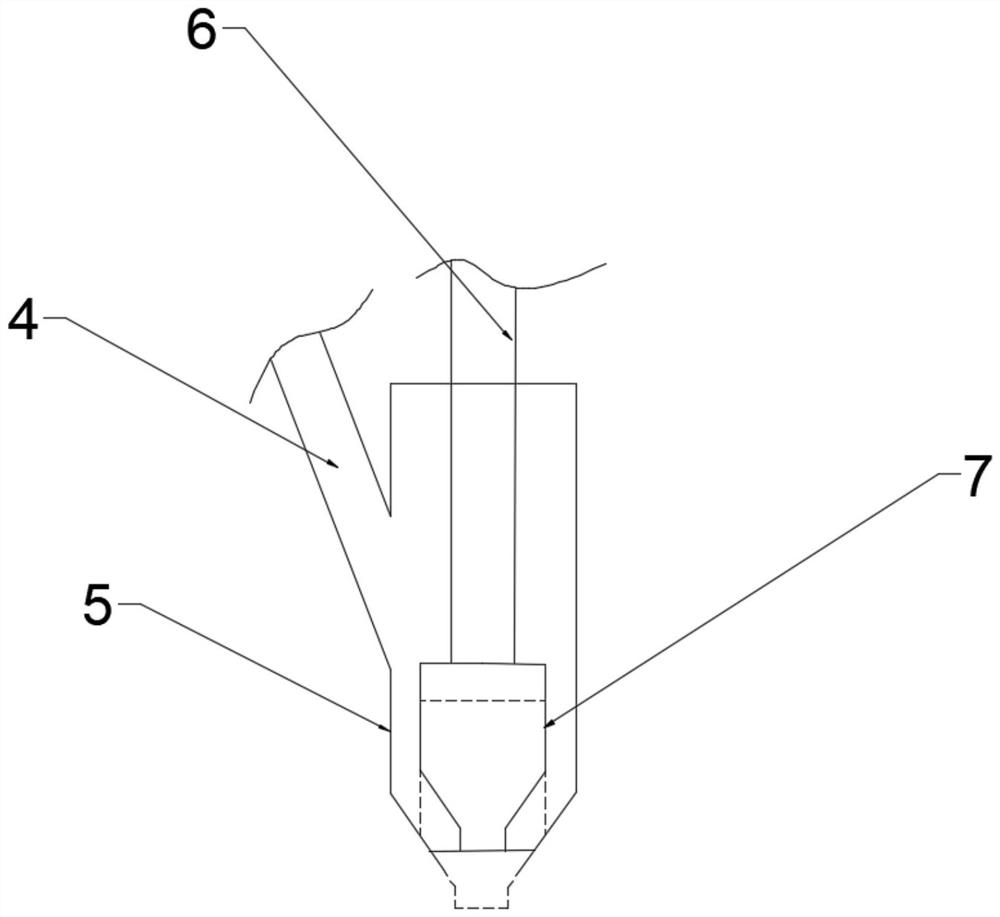

[0039] Such as figure 1 , 2 As shown, the difference between this embodiment and Embodiment 1 is that the fertilization device includes a storage hopper 3, a connecting pipe 4, a discharge cylinder 5, a first hydraulic push rod 6 and a piston head 7, and the storage hopper 3 is embedded On the support platform 1, the outlet end of the storage hopper 3 communicates with the discharge cylinder 5 through the connecting pipe 4, and the body of the first hydraulic push rod 6 is fixed on the bottom of the support platform 1 , the output end of the first hydraulic push rod 6 passes through and extends into the discharge cylinder 5 and then is fixedly connected with the piston head 7, the bottom of the discharge cylinder 5 is provided with a discharge port, the The first hydraulic push rod 6 drives the piston head 7 to move up and down, so that the piston head 7 opens or closes the discharge port.

[0040] Put the fertilizer or soil improver into the storage hopper 3. After the hole...

Embodiment 3

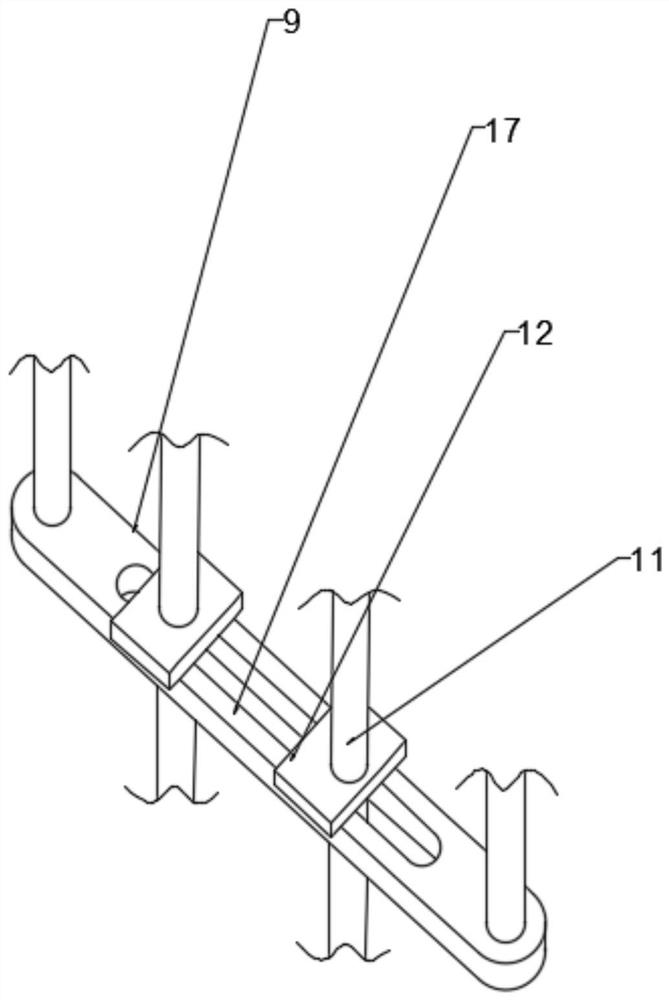

[0042] Such as Figure 3-7 As shown, the difference between this embodiment and Embodiment 1 is that the transplanting device includes a second hydraulic push rod 8, an upper support rod 9, a first telescopic spring 10, a connecting rod 11, a locking member 12, a fixed rod 16 and The lower support rod 13, the body of the second hydraulic push rod 8 is fixed on the bottom of the support table 1, the output end of the second hydraulic push rod 8 is fixedly connected to the middle part of the upper support rod 9, two The upper end of the fixed rod 16 is fixedly connected with the two ends of the upper support rod 9 respectively, and the lower support rod 13 is arranged vertically below the upper support rod 9 and is connected with the two fixed rods 16 by two The upper support rod 9 is fixedly connected, and the two connecting rods 11 are arranged vertically and at intervals on the upper support rod 9, and are all connected to the upper support rod 9 by hinges. There are strip h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com